Machine vision and scanning detection device and working method thereof

A technology of scanning detection and machine vision, which is applied in the field of part size detection, can solve the problems of inconvenient positioning and pick-and-place, low scanning detection efficiency, and narrow application range, etc., to achieve lower precision requirements, broaden adaptation and general performance, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

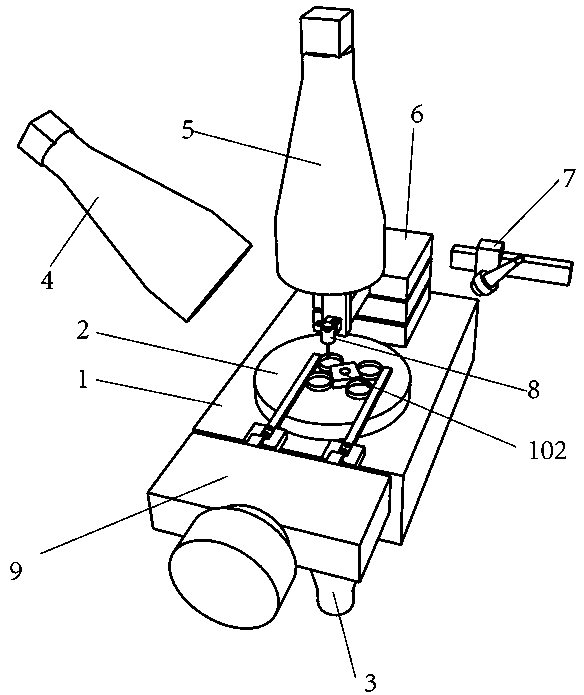

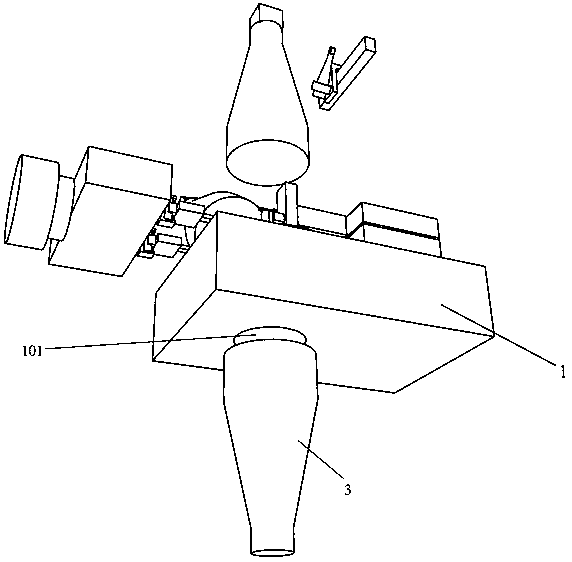

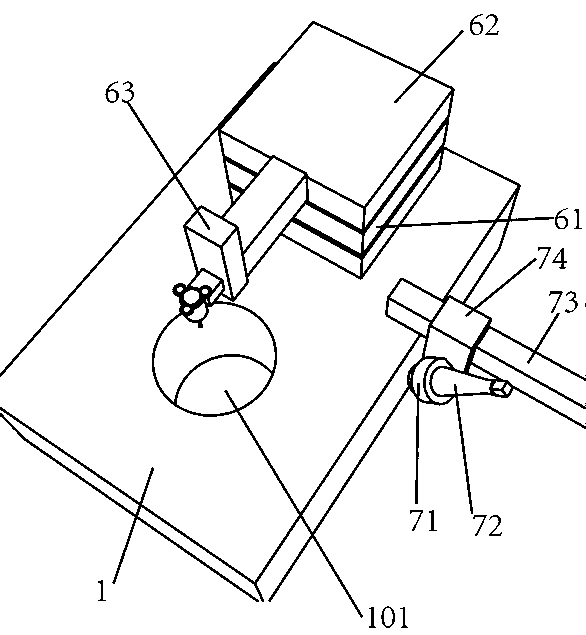

[0043] like Figure 1-8 As shown, a machine vision and scanning detection device includes a detection platform 1, and a perspective hole 101 is provided up and down on the detection platform. The upper surface of the detection table is fixed with a transparent platform 2, and a second camera 5 is erected directly above the transparent platform. One side of the second camera forms a certain angle with the second camera and is aligned with the transparent platform to erect the first camera 4. The other side of the second camera forms a certain angle with the second camera and aligns with the transparent platform to set up a structured light scanning mechanism 7, and the front side of the detection table is provided with a movable fixture 9, which extends to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com