Lead zinc ore shallow underground mining, separating and filling integrated system

A lead-zinc ore, shallow technology, applied in ore dressing system, lead-zinc ore mining field, can solve the problems of small-scale production capacity, inability to realize water recycling, no integrated footprint of concentrated ore, etc., to achieve good production convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] The preferred embodiment of the integrated system for shallow underground mining, selection and filling of lead-zinc mines of the present invention is:

[0036] include:

[0037] Underground mining lifting and waste rock transfer systems, underground crushing systems, underground concentrator systems, filling systems and auxiliary production facilities are all arranged in shallow strata;

[0038] The integrated system for shallow underground mining, selection and filling of the lead-zinc mine adopts a mixed well and a ramp to jointly develop a transportation system. The underground mining hoist system, underground concentrator system, filling system and auxiliary production facilities are connected to the ground through the ramp, And has an independent ventilation system and a second safety exit;

[0039] The shallow underground mining, dressing and filling integrated system of the lead-zinc mine has only ramp exits and return air shafts arranged on the surface, and the surface...

specific Embodiment

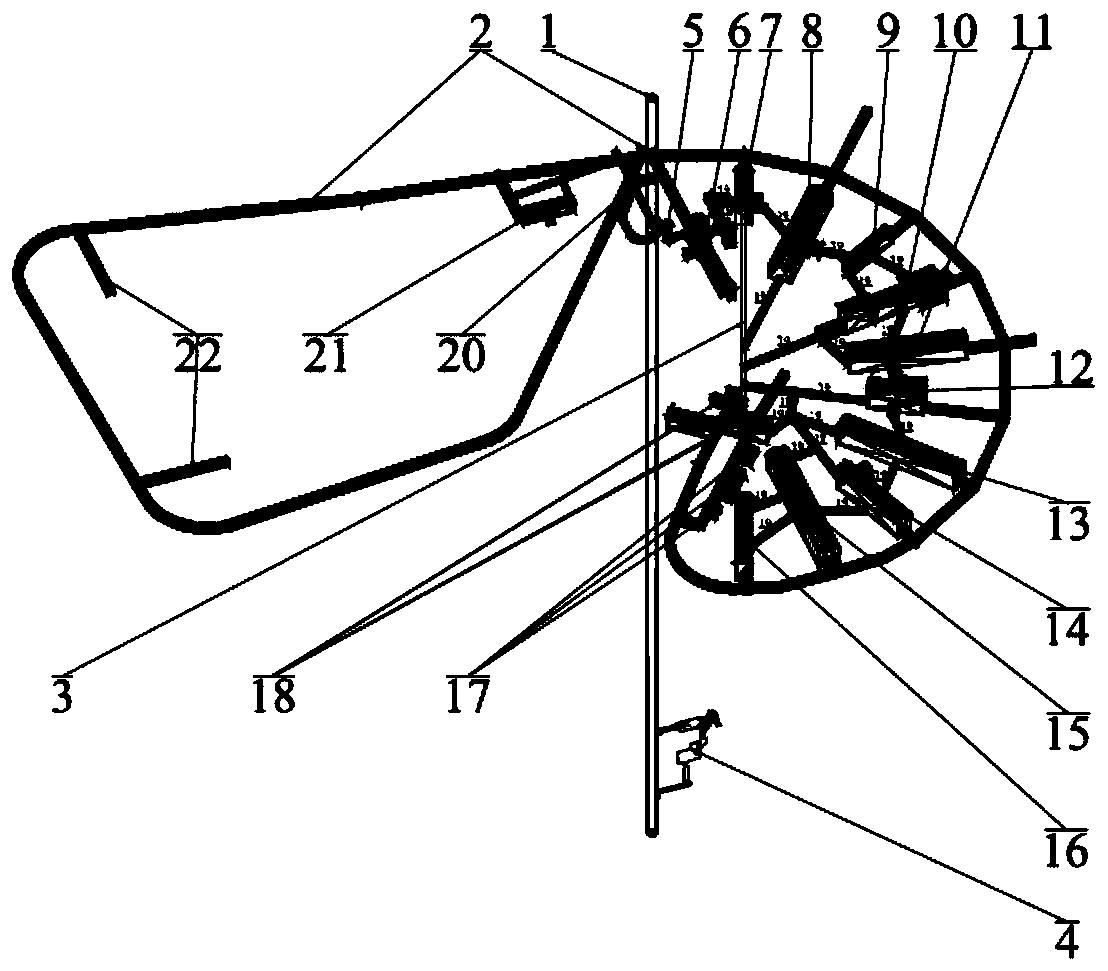

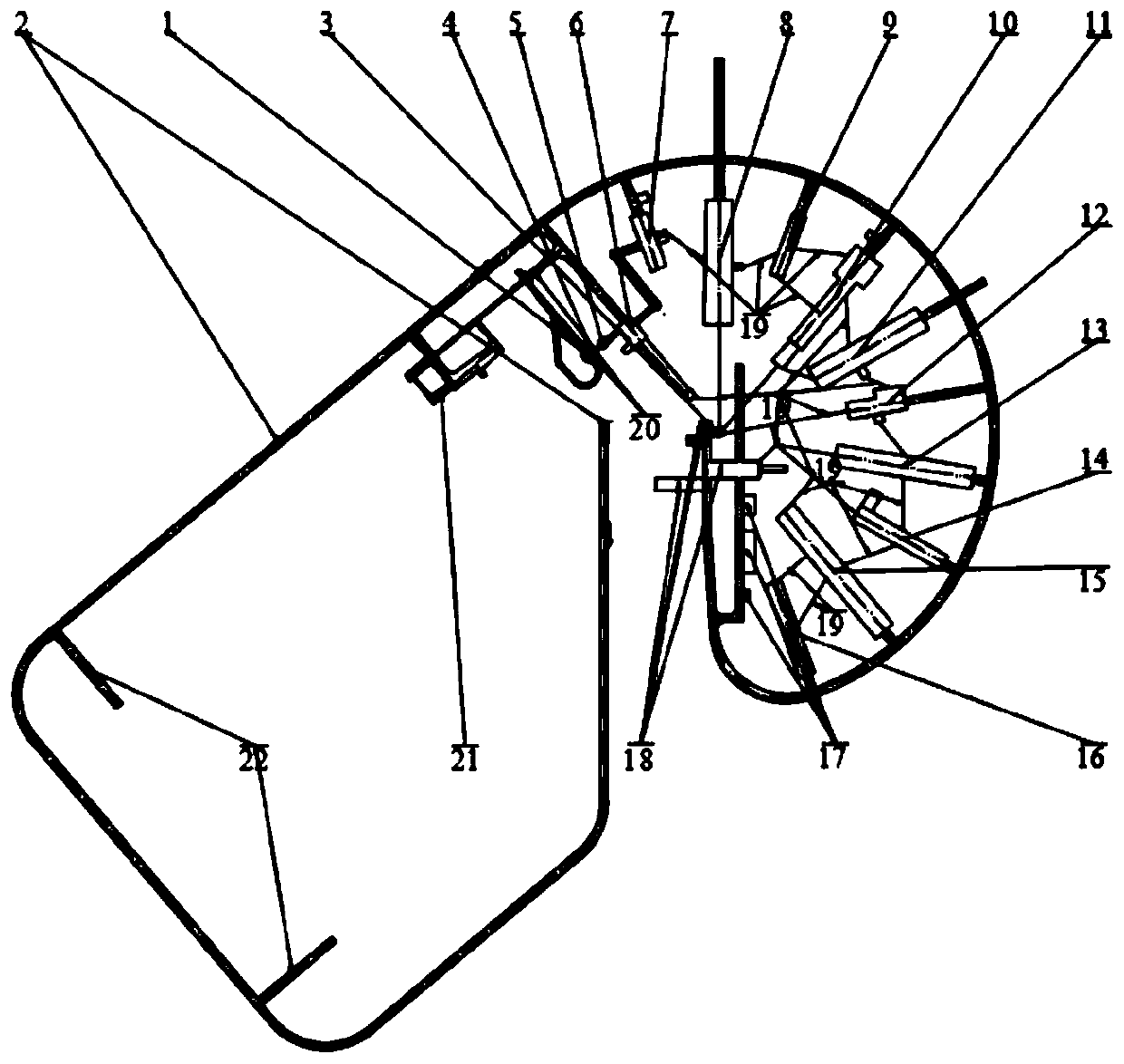

[0047] An integrated system for shallow underground mining, selection and filling of lead-zinc mines, such as figure 1 , figure 2 Shown:

[0048] (1) Underground mining lifting and crushing system

[0049] 1) The embodiment system uses a mixed well as the underground mining hoisting system, the wellhead coordinates Y=3558134.24; X=40399019.72; Z=+22m, the bottom elevation is -747m, the net diameter of the wellbore is φ6.5m, and concrete support is adopted. The thickness is 400mm. Cages and skips are arranged in the shaft, which is responsible for the transportation of ore, waste rock, equipment, materials, and personnel access. The surface facilities of the mixed wells are semi-buried shaft towers, and the discharging yards, waste rock and personnel material vehicles are arranged in underground methods, connected to the ground through ramps. There is a ladder room in the shaft as a safety exit.

[0050] 2) The ore primary crushing chamber of the embodiment system is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com