Integral vibration reduction sleeper wrapped by polyurethane

A polyurethane, integral technology, used in tracks, roads, ballast layers, etc., can solve the problems of insufficient restraint strength, fast aging speed, and failure of vibration reduction effect, and achieve excellent vibration isolation performance, good water resistance, and high quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

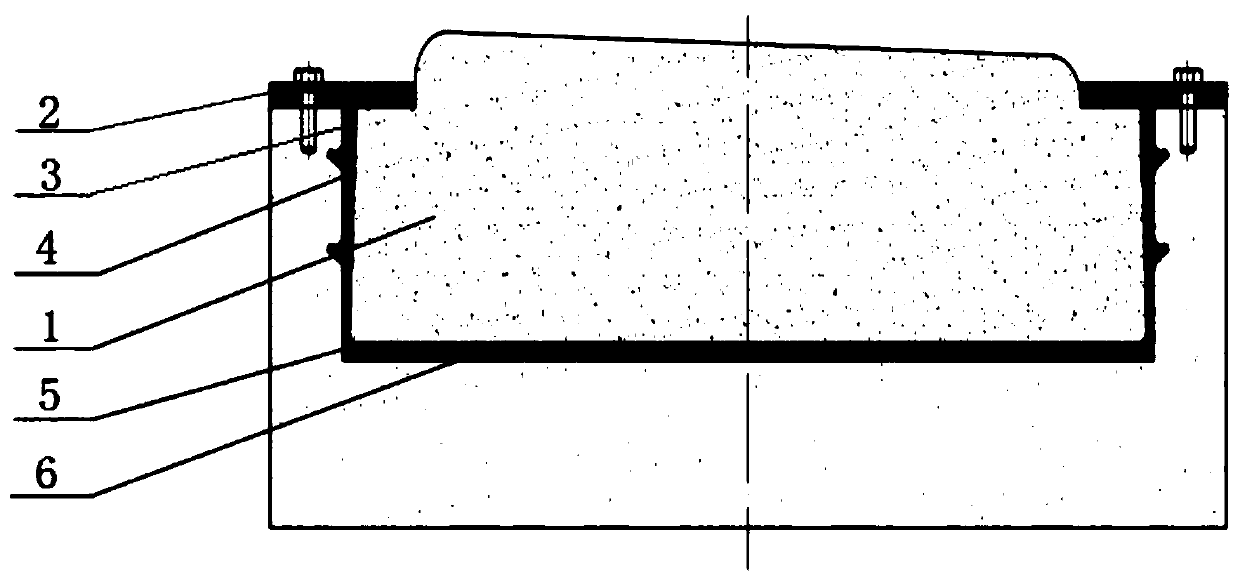

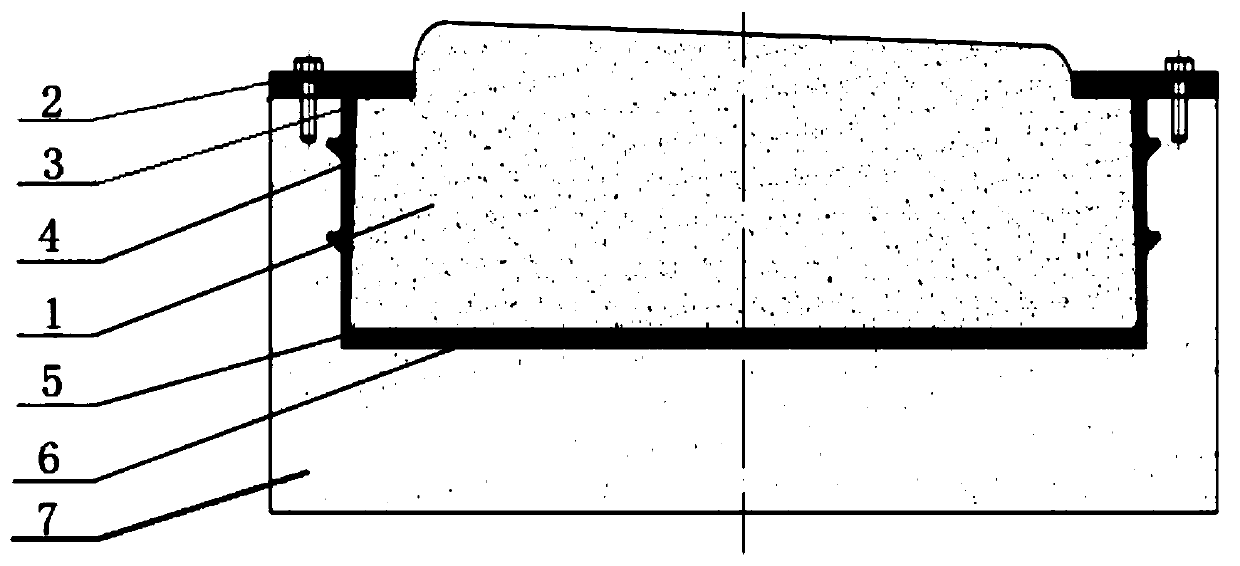

[0029] The polyurethane-wrapped integral vibration-absorbing sleeper is installed directly under the rail and inside the concrete of the ballast bed; specifically, it is achieved by the following methods, please refer to figure 2 , there is a U-shaped cavity inside the ballast bed 7, one end of the elastic withholding plate 2 is fixed on the ballast bed 7, and the elastic withholding plate 2, the sealing layer 3, the polyurethane isolation layer 4, the filling protection layer 5 and the polyurethane elastic layer 6 are formed inside the ballast bed 7 Install the concave-shaped cavity of the sleeper body 1. In the present embodiment 1, the sleeper body 1 is preferably convex, and the convex-shaped sleeper body 1 is installed on the elastic buckle plate 2 and the sealing layer 3, the polyurethane isolation layer 4, and the filling protection. Layer 5 and polyurethane elastic layer 6 formed in the concave cavity. One end of the elastic crimping plate 2 is fixed on the ballast be...

Embodiment 2

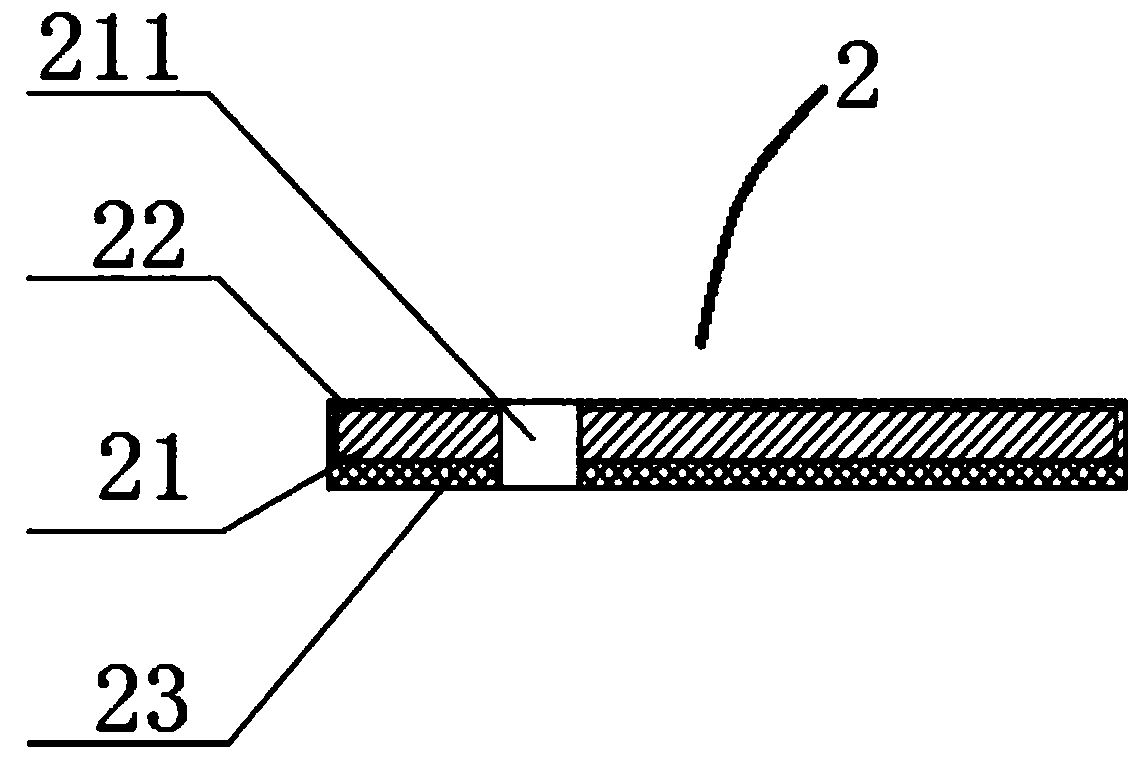

[0031] see image 3 as well as Figure 4 The elastic crimping plate 2 includes a metal branch 21 , an insulating layer 22 and an elastic layer 23 , the insulating layer 22 covers both sides and the top of the metal branch 21 , and the elastic layer 23 covers the bottom of the metal branch 21 . Both ends of the metal branch 21 are provided with fixing holes 212 . The installation and fixing holes are preferably strip-shaped holes, and the number is preferably 2. In this implementation 2, the elastic buckle plate 2 provides a vertical downward constraint to maintain the stability of the overall system of the vibration-damping sleeper; the elastic layer 23 is used for The impact of the sleeper body 1 on the elastic buckle plate 2 is buffered, and the insulating layer 22 wrapped around and on the top of the metal branch 21 is used for insulation and anticorrosion.

Embodiment 3

[0033] see Figure 5 as well as figure 2 , Polyurethane isolation layer 4 adopts polyether polyurethane, which has superior water resistance, aging resistance, wear resistance, and vibration reduction and isolation performance. The polyurethane isolation layer 4 is bonded with the sleeper body 1 by mold casting, which enhances the bonding force between the polyurethane isolation layer 4 and the sleeper body 1, and is firm and stable in quality, while ensuring the lateral binding force of the vibration-damping sleeper. It solves the problem that the rubber boots and the sleeper body are connected in the form of cold bonding and binding in the existing sleeper vibration reduction, which is easily affected by the construction quality and the later vehicle operation. Hanging, the gauge changes greatly, which leads to the failure of the vibration reduction effect and affects the driving safety. The outer side of the polyurethane isolation layer 4 is provided with a reverse eaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com