Anaerobic decompose furnace for domestic garbage

A domestic waste and decomposition furnace technology, applied in coking ovens, coking carbon-containing materials, petroleum industry, etc., can solve the problems of difficult disposal, long decomposition time, and high energy consumption, and achieve the effect of low energy consumption for waste decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

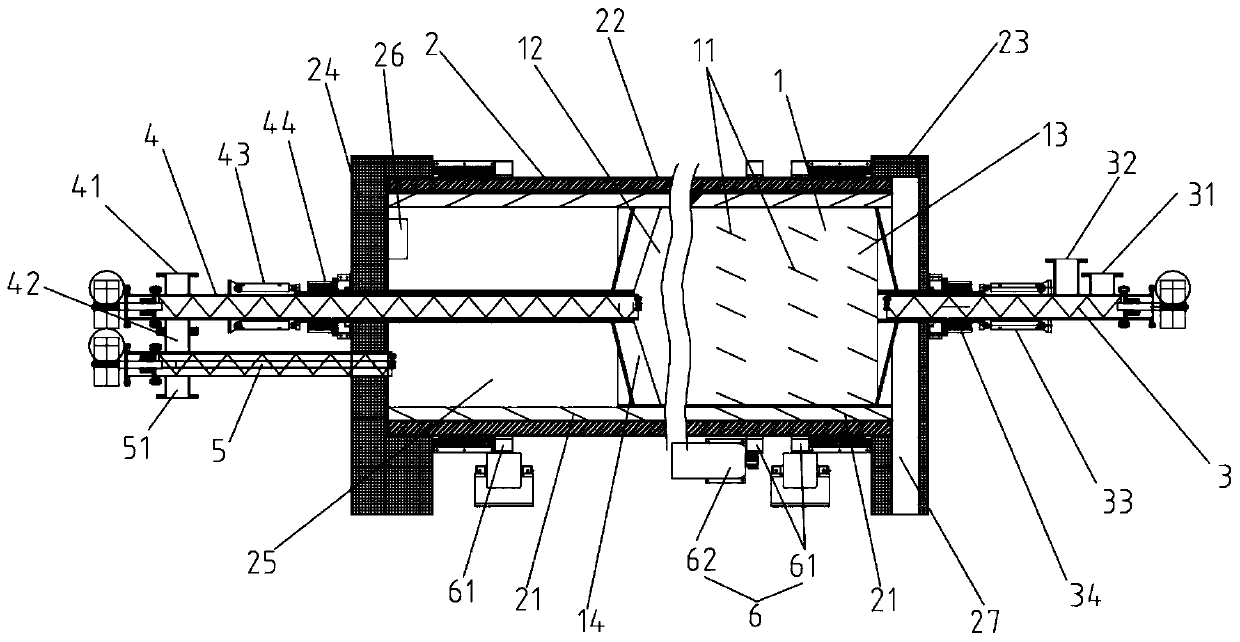

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] like figure 1As shown, the domestic waste anaerobic decomposition furnace disclosed by the present invention includes an inner cylinder 1, an outer cylinder 2, a drive mechanism 6, a first feeder 3, a second feeder 5 and a discharger 4, an outer cylinder 2 and The inner cylinder 1 is horizontal, the inner cylinder 1 is made of heat-conducting material, the outer cylinder 2 is made of thermal insulation material, the driving mechanism 6 is connected with the outer cylinder 2, the inner cylinder 1 is inside the outer cylinder 2 and the inner cylinder 1 and the outer cylinder 2 Coaxial fixed connection, the outer cylinder 2 has a heating chamber 25 between its rear end and the rear end of the inner cylinder 1, the heating chamber 25 is provided with a heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com