Environmental-protection paint spraying chamber

A spray booth, environmental protection technology, applied in the field of spray booths, can solve the problems of paint waste, paint mist suction and recovery, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

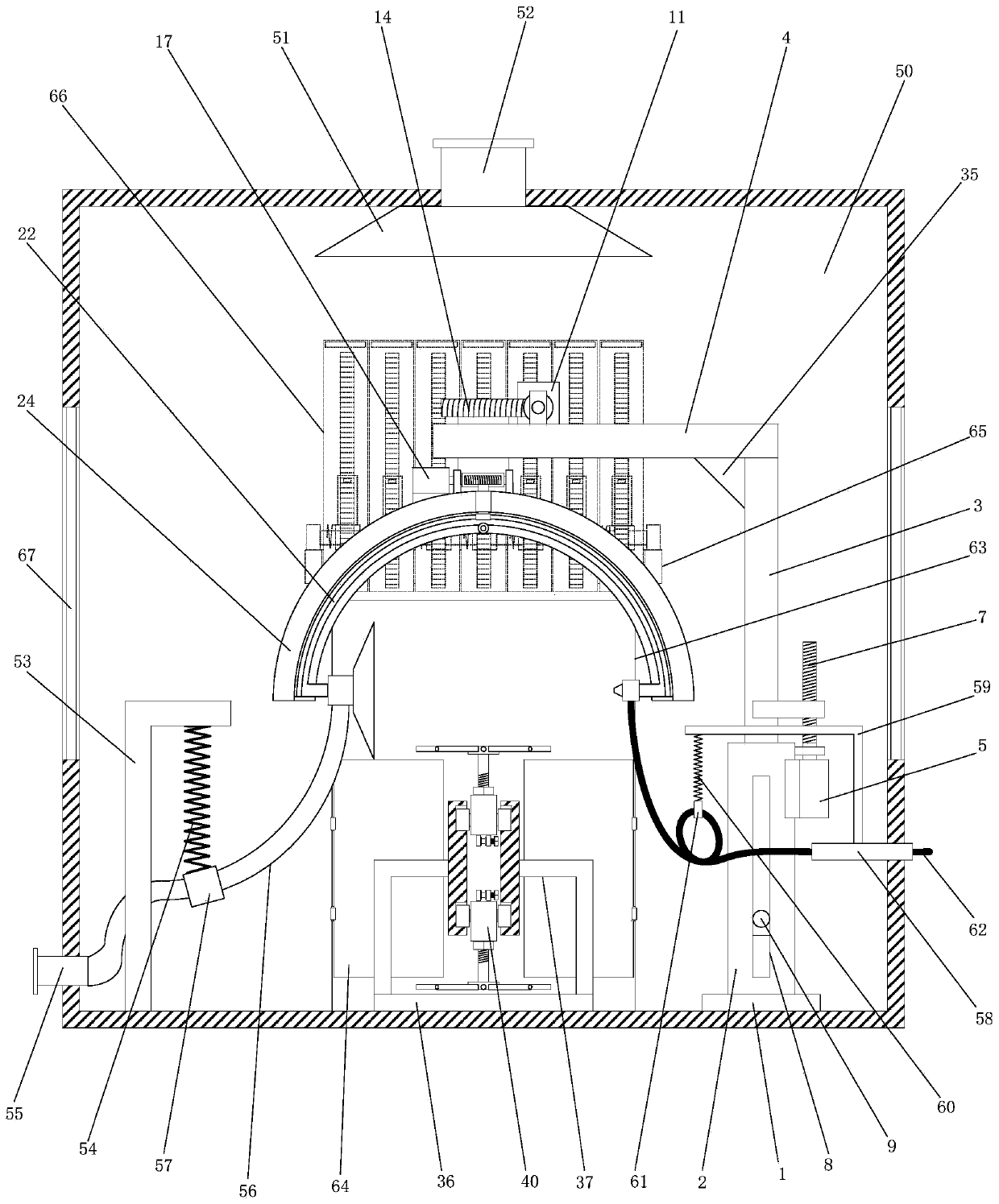

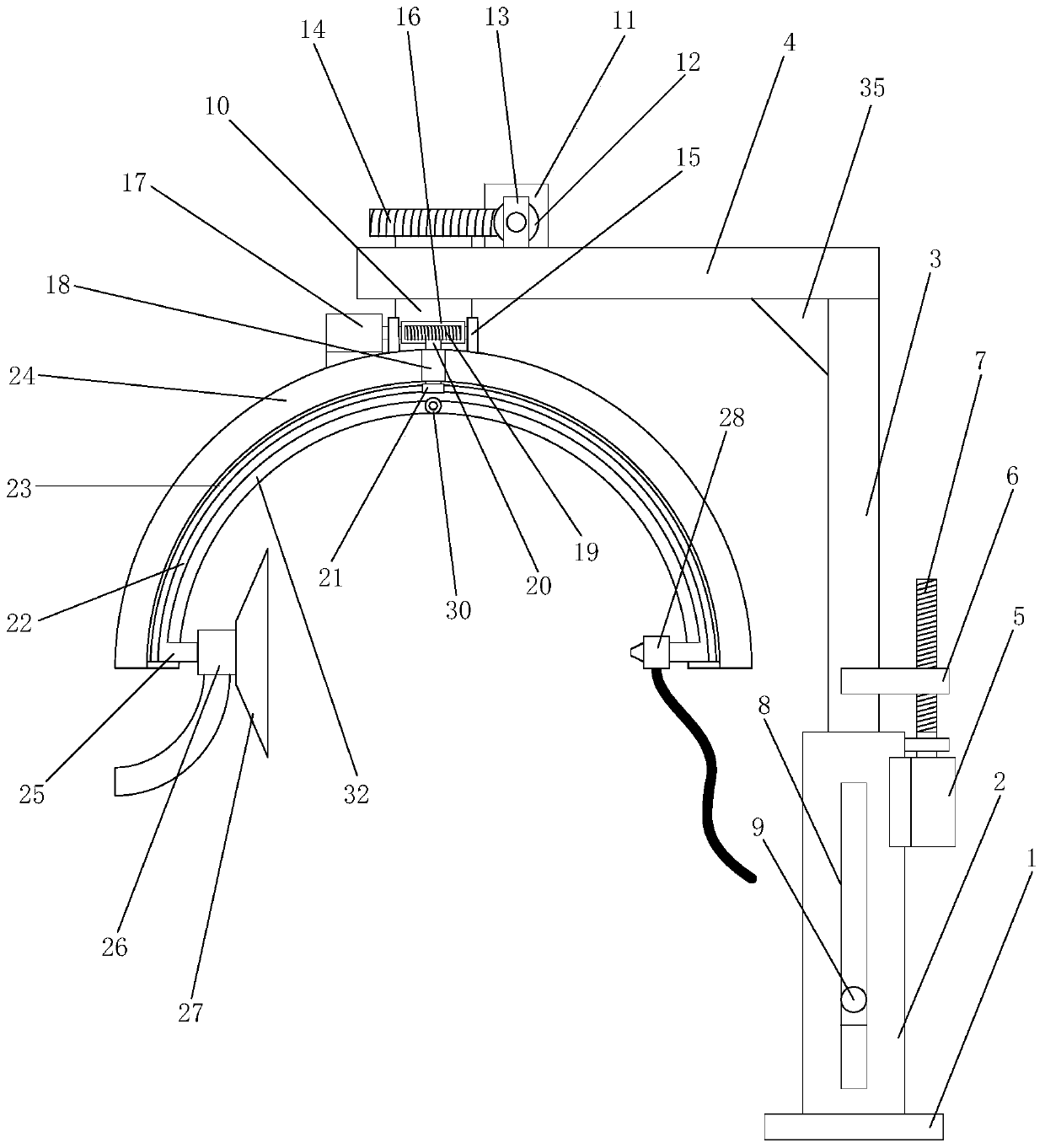

[0026] Such as Figure 1-5 As shown, the environmental protection spray booth disclosed by the present invention includes: a rotary paint spraying mechanism, a workpiece conveying mechanism and a rectangular parallelepiped housing 50;

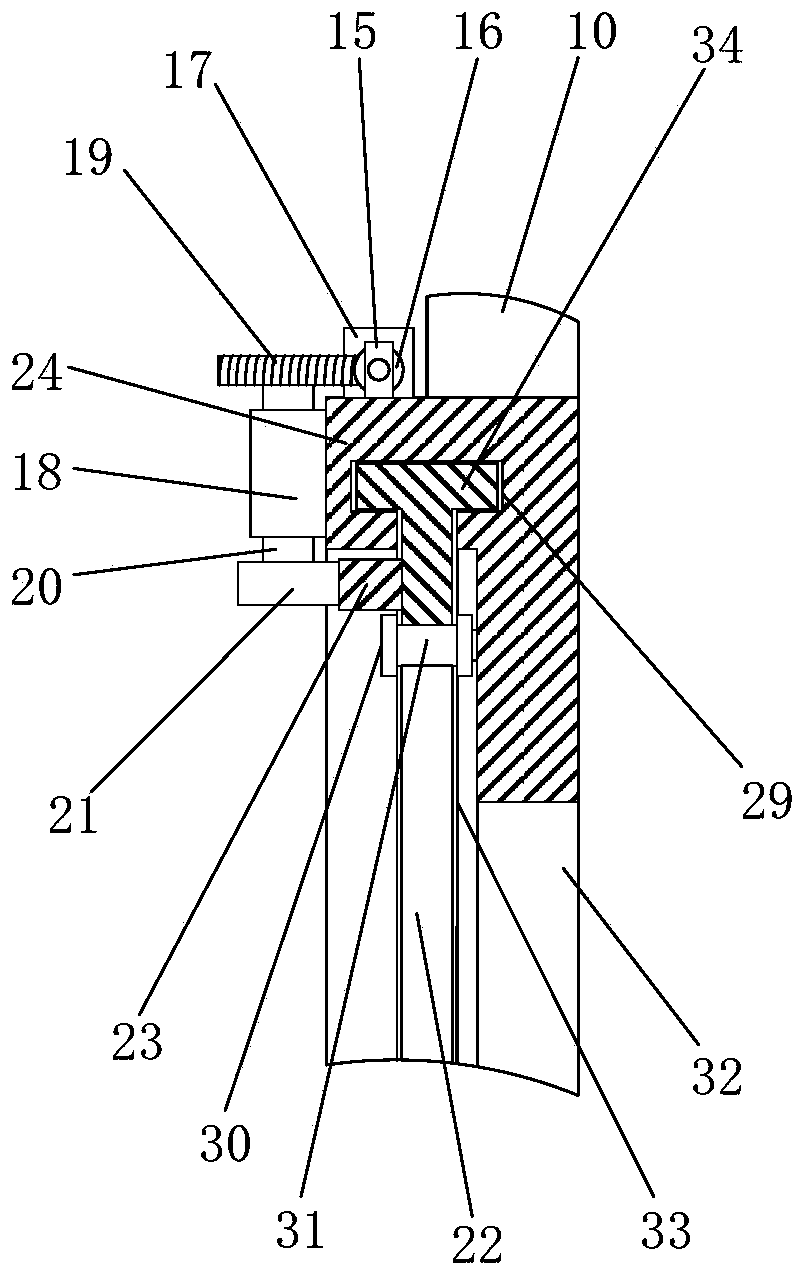

[0027] The rotary painting mechanism includes a lifting bracket, a transverse beam 4, a rotary drive motor 11, an angle adjustment motor 17, a suction cone cover 27, a paint nozzle 28, a semicircular arc plate 24 and a semicircular annular plate 22;

[0028] The lifting bracket is fixedly installed on the bottom of the painting station in the housing 50; one end of the transverse beam 4 is fixedly installed on the lifting bracket; the other end of the transverse beam 4 is vertically rotatably installed with a suspension shaft 10; A rotary drive worm gear 14 is fixedly installed on the upper end of the suspension shaft 10; a rotary drive worm 12 is rotatably installed on the transverse beam 4 through the upper side worm support 13; the rotary dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com