Robot spraying trajectory planning method based on large complex curved surface model

A complex surface and trajectory planning technology, applied in the direction of injection device, design optimization/simulation, etc., can solve the problems of linkage control difficulty, cost increase, and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0049] The robot spraying trajectory planning method based on a large complex curved surface model disclosed by the present invention first performs digital-analog off-line planning, and then performs actual spraying planning;

[0050] The specific steps of the digital-analog offline planning process are as follows:

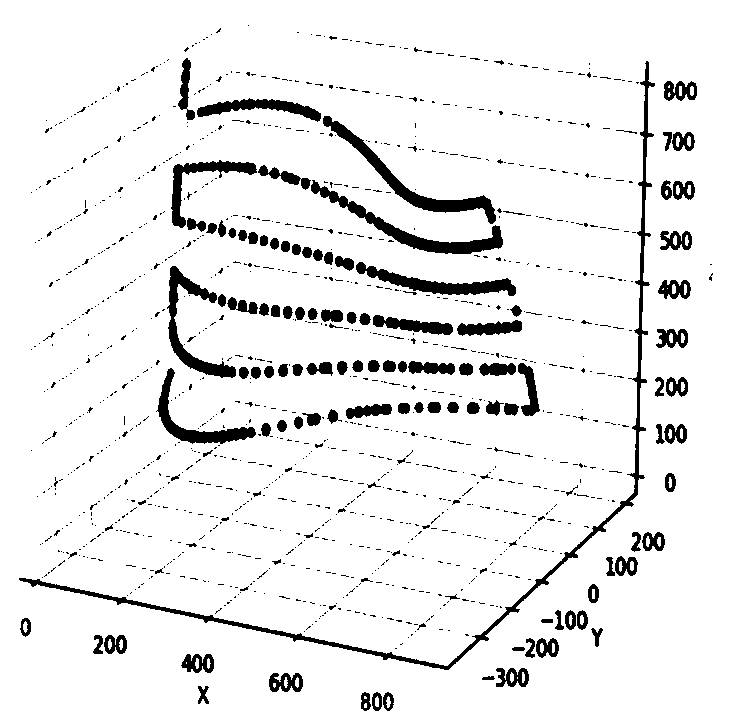

[0051] Step 1, such as figure 1 As shown in the first part of the flow chart, according to the assembly relationship between the X, Y, Z three-degree-of-freedom mobile platform and the robot used in the actual spraying, as well as the assembly relationship between the spraying tool and the robot, the following is established in the CAD software: figure 2 The X, Y, Z three-degree-of-freedom mobile platform model, robot model and spray gun tool model are shown. Among them, the base of the robot model is fixedly connected with the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com