Light-weight wood structure heat-insulation and sound-insulation fabricated wall body

A technology of thermal insulation, sound insulation, and wooden structure, which is applied to walls, building components, building structures, etc., and can solve the problems of poor sound insulation and thermal insulation effects of light walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

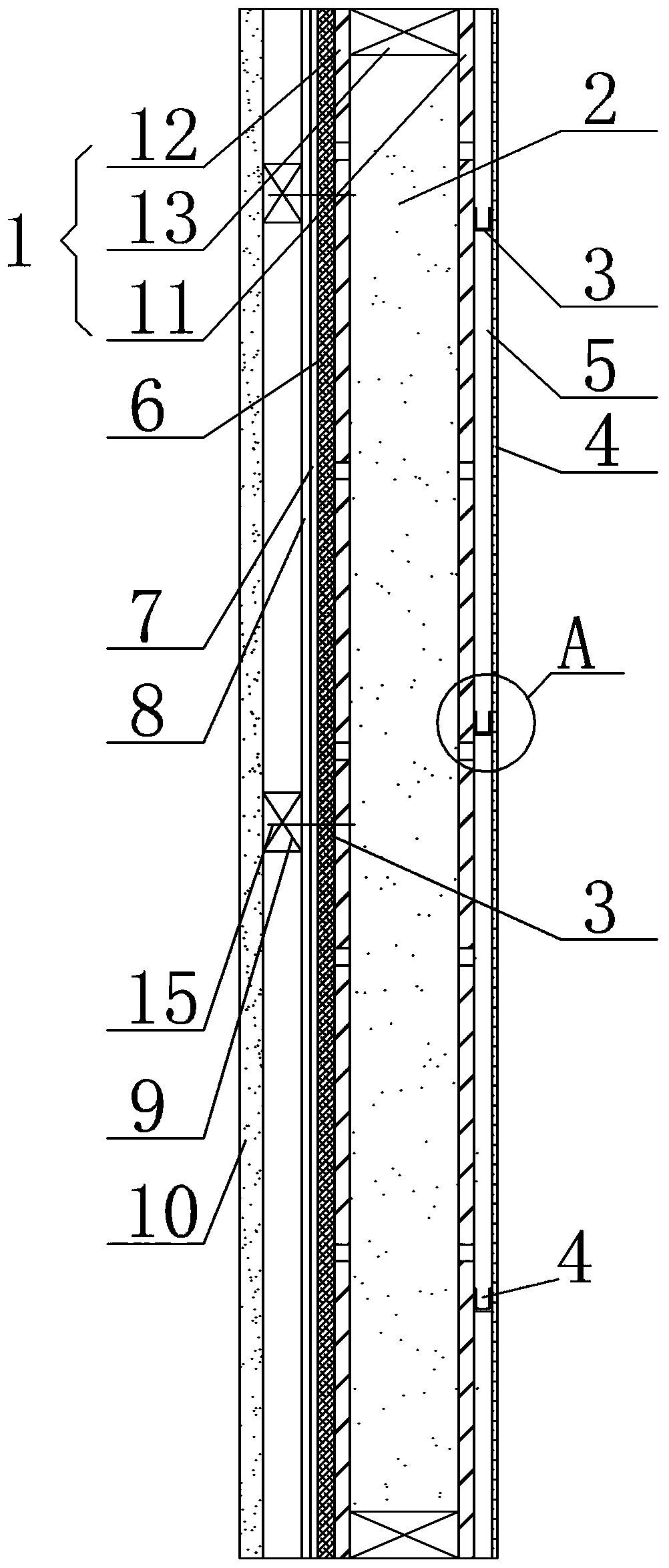

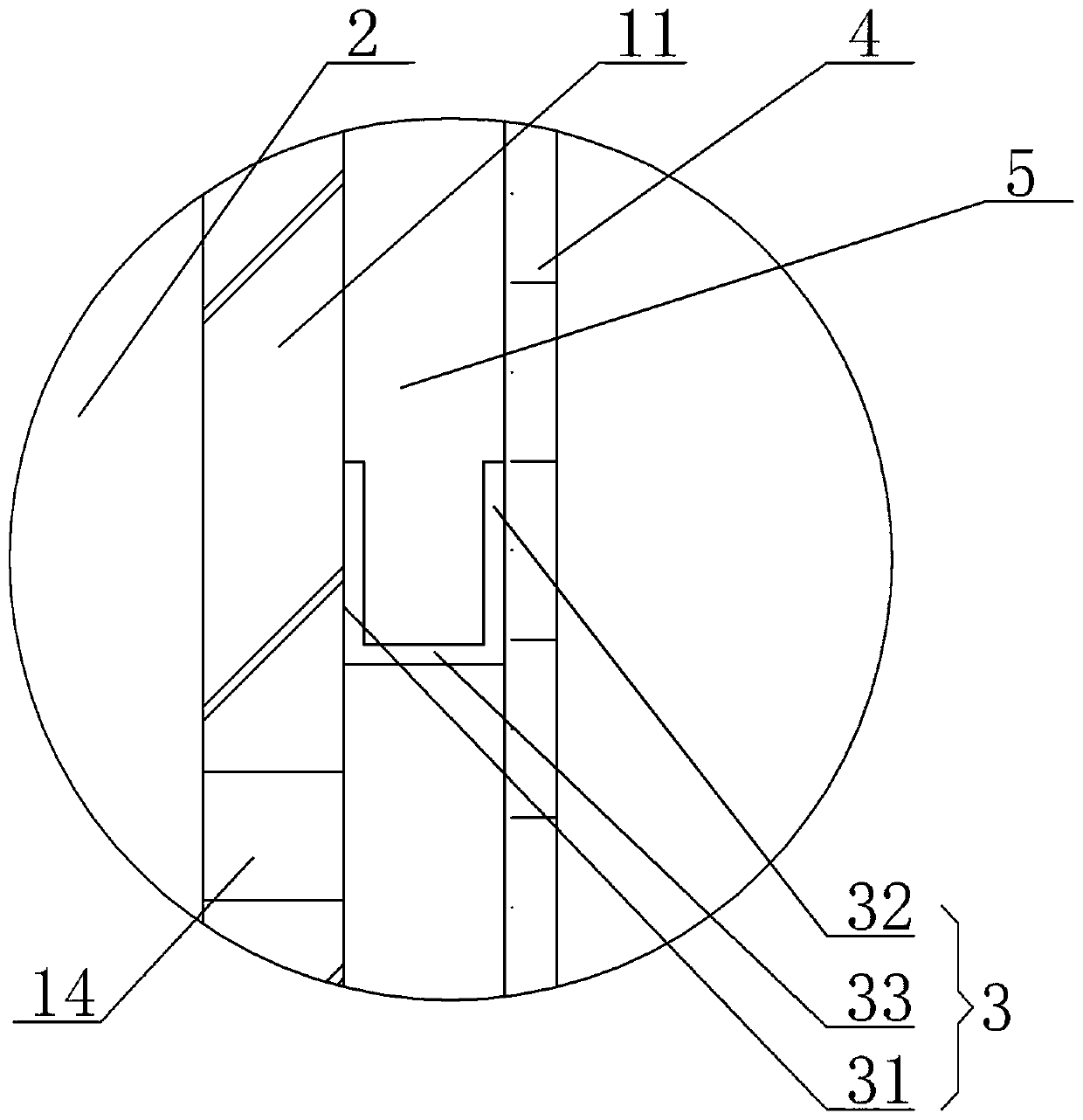

[0019] Assembled wall for thermal insulation and sound insulation of light wood structure, see figure 1 , figure 2 : It includes a frame structure 1 with an inner cavity structure formed by wooden standard materials, the inner cavity of the frame structure 1 is filled with thermal insulation cotton 2, the frame structure 1 includes two side panels for fixing the wall, respectively It is an inner side plate 11 and an outer side plate 12. The inner side plate 11 of the frame structure 1 is covered with a number of connecting cross bars 3 arranged in parallel from top to bottom, and each connecting cross bar 3 includes a first transverse connecting part 31, The second transverse connecting portion 32, the outwardly convex connecting portion 33, the first transversely connecting portion 31 is used to fix the inner side plate 11 at the corresponding position of the frame structure 1, and the two sides of the outwardly protruding connecting portion 33 relative to the thickness dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com