An automatic nail insertion device for prefabricated laminated panels with self-contained positioning nails

A technology of positioning nails and laminated plates, which is applied in nailing tools, supply devices, nailing tools, etc., can solve the problems of affecting the installation of heating pipes, difficulty in drilling holes, and falling off, and achieves a fast and automated nailing method. High, increase the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

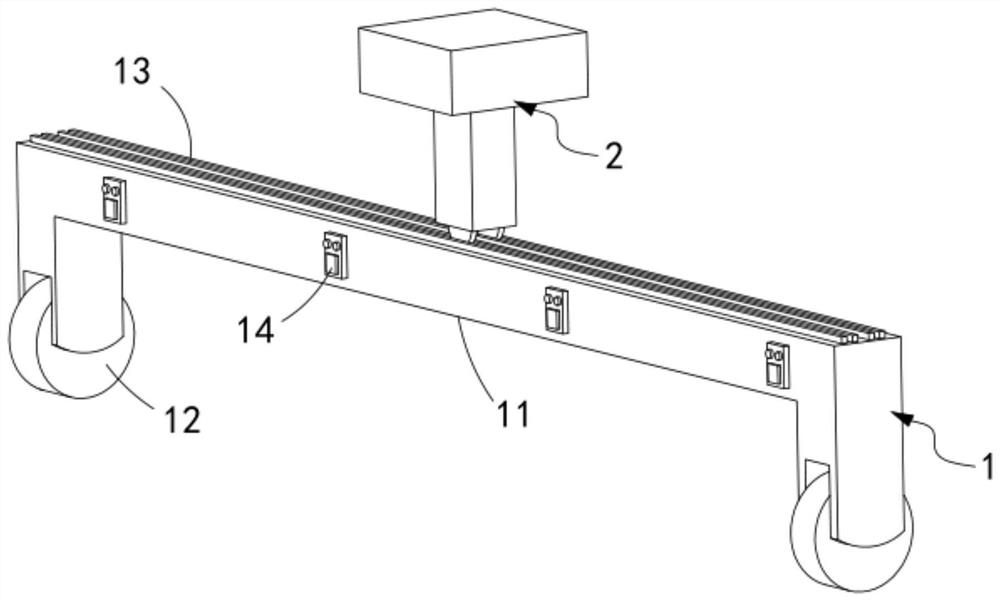

[0069] Such as figure 1 Shown, a kind of plug-in nail 10 retainer, comprising:

[0070] A transverse sliding mechanism 1, which straddles above the prefabricated slab and slides back and forth along the length direction of the prefabricated slab is arranged on the prefabricated slab;

[0071] A longitudinal sliding mechanism 2, the longitudinal sliding mechanism 2 is slidably arranged on the horizontal sliding mechanism 1 along the length direction of the horizontal sliding mechanism 1;

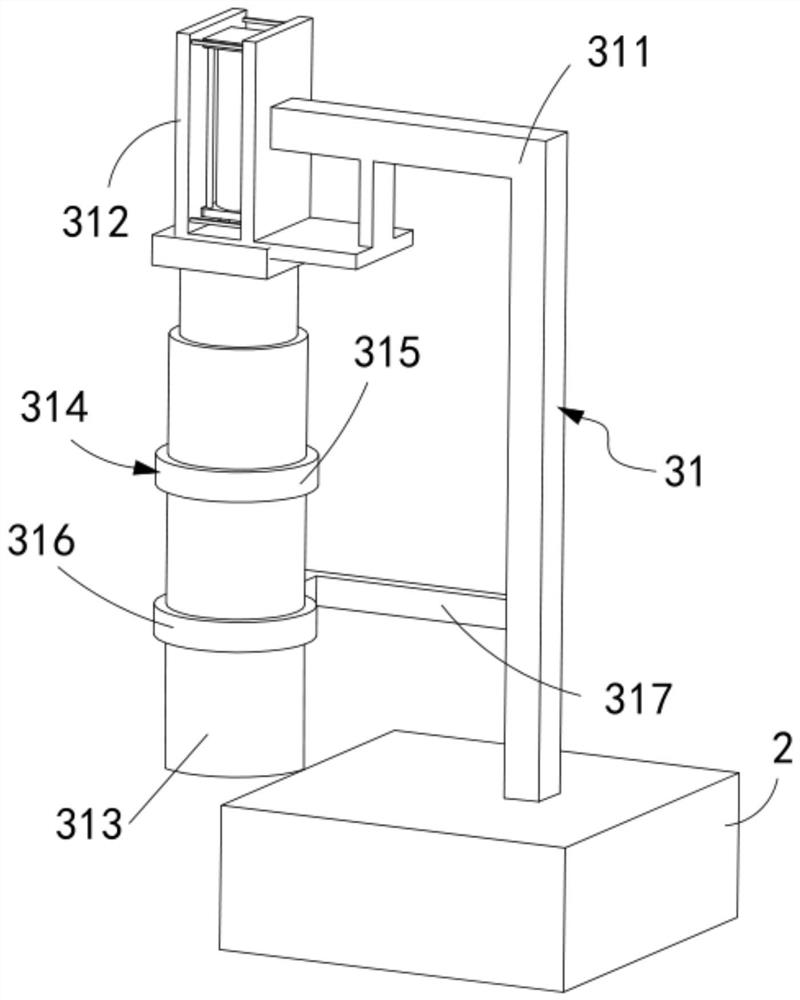

[0072] Nail-introducing mechanism 3, said nail-introducing mechanism 3 includes an insertion assembly 31 arranged on said longitudinal sliding mechanism 2, used for digging holes on the prefabricated board in the closed state and dispersing the cement in the open state into the pits The mud collection assembly 32, the pressure limiting assembly 33 which is sleeved on the insertion assembly 31 and used to limit the cement breaking, and the mud collection assembly 32 is set in conjunction with...

Embodiment 2

[0114] Such as Figure 10 , Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0115] further, such as Figure 10 , Figure 11 As shown, the control assembly 34 includes:

[0116] Positioning rod 341, the positioning rod 341 is fixedly connected with the pull rod b329 and it is arranged in an L-shaped structure, the positioning rod 341 is provided with several groups corresponding to the pull rod b329; and

[0117] Feed groove 342, described feed groove 342 is opened in described gun barrel 313 and its length direction is vertically set with described gun barrel 313 length direction, and described positioning rod 341 is slidably arranged in described feed groove 342 and Sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com