Method for repairing overall non-excavation sewage pipe through hot water overturning curing

A sewage pipeline, trenchless technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of excavation and construction, and achieve the effect of reducing cost, fast speed and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

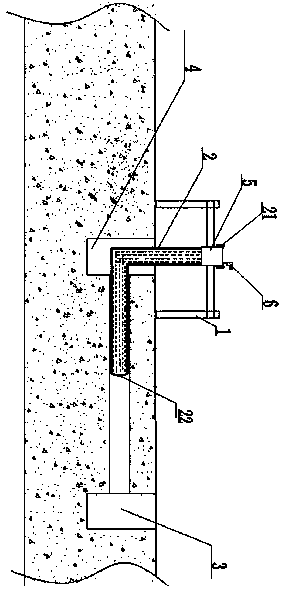

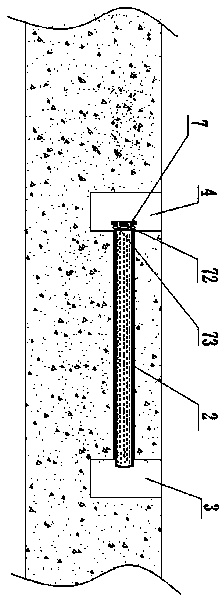

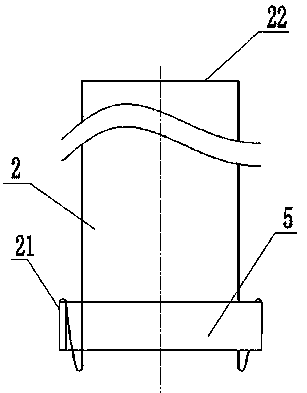

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0033] This embodiment discloses a method for overall repair of trenchless sewage pipelines by using hot water inversion and solidification, including the following steps:

[0034] (1) Clean the pipeline between the two sewage wells 3 and 4;

[0035] (2) After the cleaning is completed, the water in the pipeline is pumped out by the pump;

[0036] (3) Use the closed-circuit television system to detect the cleaned pipeline, collect the image of the inner wall of the pipeline through the camera, find out the damage, and judge whether it meets the repair requirements, whether there is structural damage, such as collapse, if there is no structural damage Damage, such as cracks, etc. can be carried out to the next step, of course, it can also be detected manually, and the manual d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com