Air intake control method of combustion chamber

A control method, combustion chamber technology, applied to fuel air intakes, combustion air/combustion-air handling, combustion engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings.

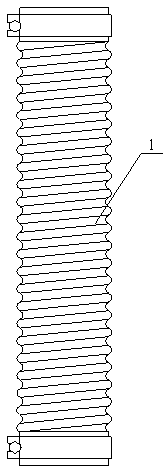

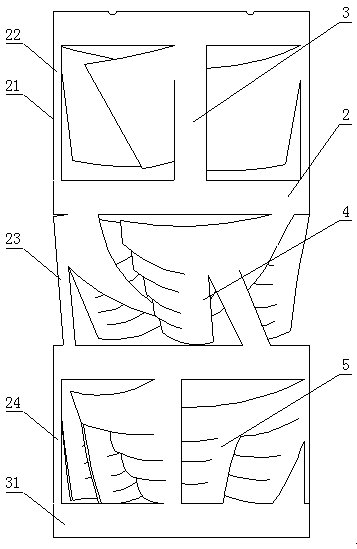

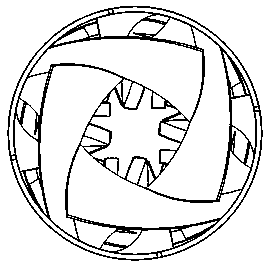

[0057] During specific implementation: if Figure 1 to Figure 14 As shown, a combustion chamber air intake control method relies on physical separation to process the air before entering the engine combustion chamber, so that before the air enters the engine, it completes the unfavorable combustion components represented by nitrogen molecules and oxygen molecules. The representative combustion facilitates the enrichment of the respective components, and makes the two components enter the combustion chamber of the engine in their respective enriched states for combustion.

[0058]In this way, this method belongs to the engine intake front-end treatment technology, but compared with the prior art, this method does not try to completely separate the nitrogen and oxygen components in the air and control and adjust their ratio, but only completes their respective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com