Method for conducting numerical simulation on water-soluble viscosity reducer flooding of common thickened oil

A numerical simulation, water-soluble technology, applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve problems such as restricting development, inability to obtain reservoir engineering design, etc., achieving less parameter requirements, strong practicability, good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Such as figure 1 as shown, figure 1 It is the numerical simulation method of ordinary heavy oil water-soluble viscosity reducer flooding in this example.

[0036] Step 101, collecting the basic performance parameters and experimental data of the water-soluble viscosity reducer. The concentration of water-soluble viscosity reducer at room temperature is 1.02mPa.s, and the mass density is 1023kg / m 3 , when the mass concentration of the water-soluble viscosity reducer is 0.1%, 0.3%, 0.5%, 0.8%, and 1%, the concentration of the oil-water mixture obtained is 14.5, 8.4, 6.5, 5.3, and 4.7mPa.s.

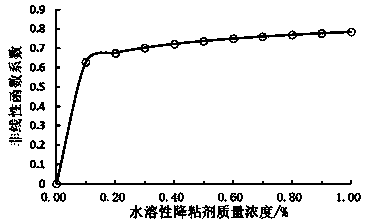

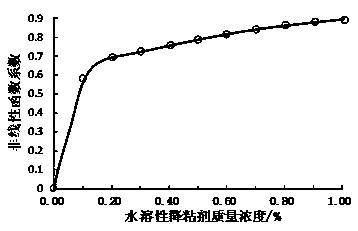

[0037] Step 102, on the basis of step 101, carry out trend line fitting to the experiment of reducing the viscosity of crude oil by water-soluble viscosity reducer, and obtain the fitted power formula:

[0038] y=4.73×x 0.486 .

[0039] Step 103, on the basis of step 102, calculate the viscosity of the oil-water mixture under different mass concentrations of the water-soluble vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com