Buried culvert desilting system

A technology of concealed culverts and rakes, which is applied in the field of decontamination equipment, can solve the problems of insufficient light in culverts, a large number of operating points, and poor visibility of dredging operations, and achieve the effect of improving dredging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

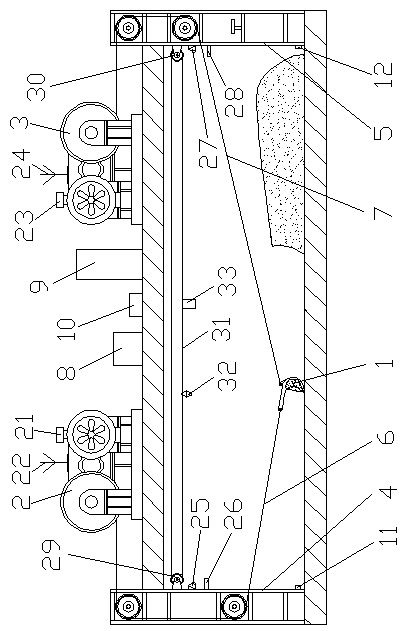

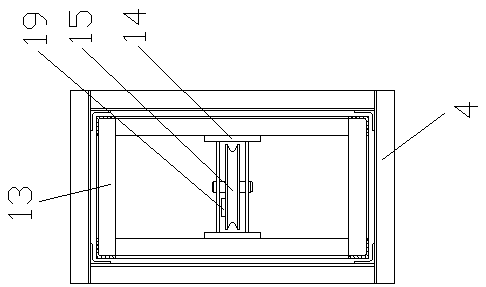

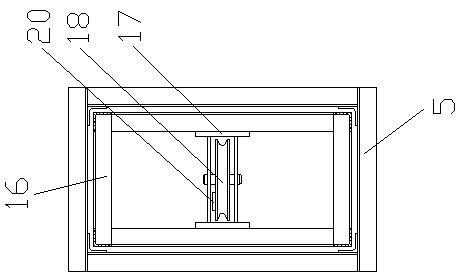

[0046] A hidden culvert dredging system, including a rake bucket 1, and also includes a main traction hoist 2, an auxiliary traction hoist 3, a main support frame 4, an auxiliary support frame 5, a main traction wire rope 6, an auxiliary traction wire rope 7, a PLC controller 8, A frequency converter 9 and a display 10 electrically connected to the PLC controller 8, a main proximity switch 11 for monitoring the position of the rake bucket 1 is fixed on the bottom of the main support frame 4, and a main proximity switch 11 for monitoring the position of the rake bucket 1 is fixed on the bottom of the auxiliary support frame 5. The auxiliary proximity switch 12 at the bucket 1 position, the main proximity switch 11 and the auxiliary proximity switch 12 are electrically connected to the PLC controller 8 respectively, the main traction wire rope 6 is wound on the main support frame 4, and one end of the main traction wire rope 6 is connected to the main The traction hoist 2 is conn...

Embodiment 2

[0049] A hidden culvert dredging system, including a rake bucket 1, and also includes a main traction hoist 2, an auxiliary traction hoist 3, a main support frame 4, an auxiliary support frame 5, a main traction wire rope 6, an auxiliary traction wire rope 7, a PLC controller 8, A frequency converter 9 and a display 10 electrically connected to the PLC controller 8, a main proximity switch 11 for monitoring the position of the rake bucket 1 is fixed on the bottom of the main support frame 4, and a main proximity switch 11 for monitoring the position of the rake bucket 1 is fixed on the bottom of the auxiliary support frame 5. The auxiliary proximity switch 12 at the bucket 1 position, the main proximity switch 11 and the auxiliary proximity switch 12 are electrically connected to the PLC controller 8 respectively, the main traction wire rope 6 is wound on the main support frame 4, and one end of the main traction wire rope 6 is connected to the main The traction hoist 2 is conn...

Embodiment 3

[0053] A hidden culvert dredging system, including a rake bucket 1, and also includes a main traction hoist 2, an auxiliary traction hoist 3, a main support frame 4, an auxiliary support frame 5, a main traction wire rope 6, an auxiliary traction wire rope 7, a PLC controller 8, A frequency converter 9 and a display 10 electrically connected to the PLC controller 8, a main proximity switch 11 for monitoring the position of the rake bucket 1 is fixed on the bottom of the main support frame 4, and a main proximity switch 11 for monitoring the position of the rake bucket 1 is fixed on the bottom of the auxiliary support frame 5. The auxiliary proximity switch 12 at the bucket 1 position, the main proximity switch 11 and the auxiliary proximity switch 12 are electrically connected to the PLC controller 8 respectively, the main traction wire rope 6 is wound on the main support frame 4, and one end of the main traction wire rope 6 is connected to the main The traction hoist 2 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com