Combustion type optical fiber preform stretching apparatus and control method thereof

A technology of optical fiber preform and stretching equipment, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of complex structure, large volume of high-frequency induction furnace, etc., achieve the effect of small size, improve work efficiency, and realize integrated control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

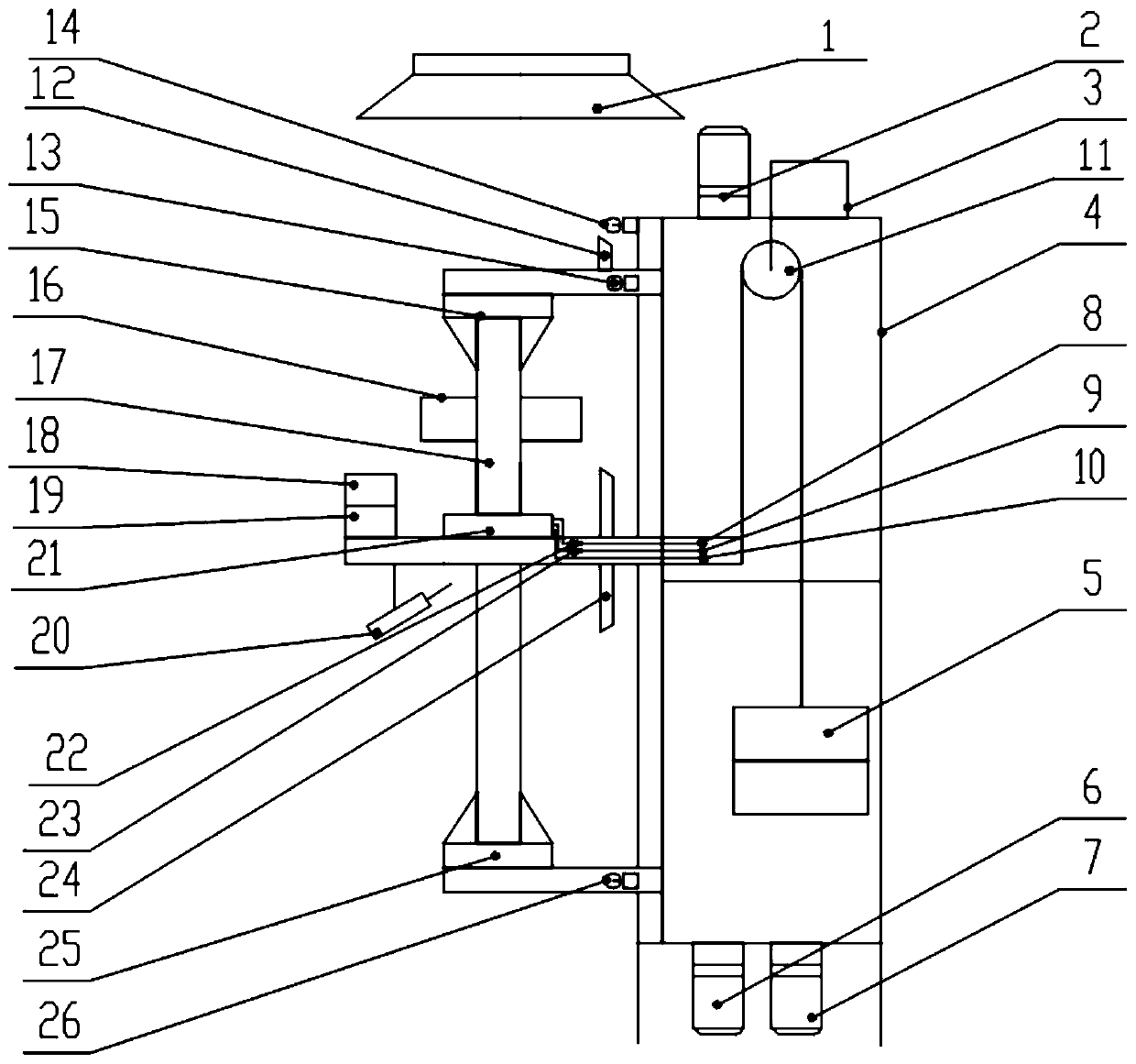

[0032] see figure 1 As shown, the embodiment of the present invention provides a combustion type optical fiber preform drawing equipment, including:

[0033]The main body of the tower, the main body of the tower includes: a tower 4 , an upper chuck device 15 , a lower chuck device 25 and an annular blowtorch 21 . The upper chuck device 15 is installed on the upper end of a pair of vertical guide rails on the front of the tower 4 through the upper chuck lifting device. The upper chuck device 15 is used to clamp the optical fiber preform 17 to move upward. The disc carrier is fixedly installed at the lower end of a pair of vertical guide rails on the front of the tower frame 4. The upper chuck device 15 and the lower chuck device 25 are used to clamp the two ends of the optical fiber preform 17 and drive the optical fiber preform 17 to rotate . The upper chuck device 15 moves up and down freely following the upper chuck lifting device to stretch the optical fiber preform 17 to...

Embodiment 2

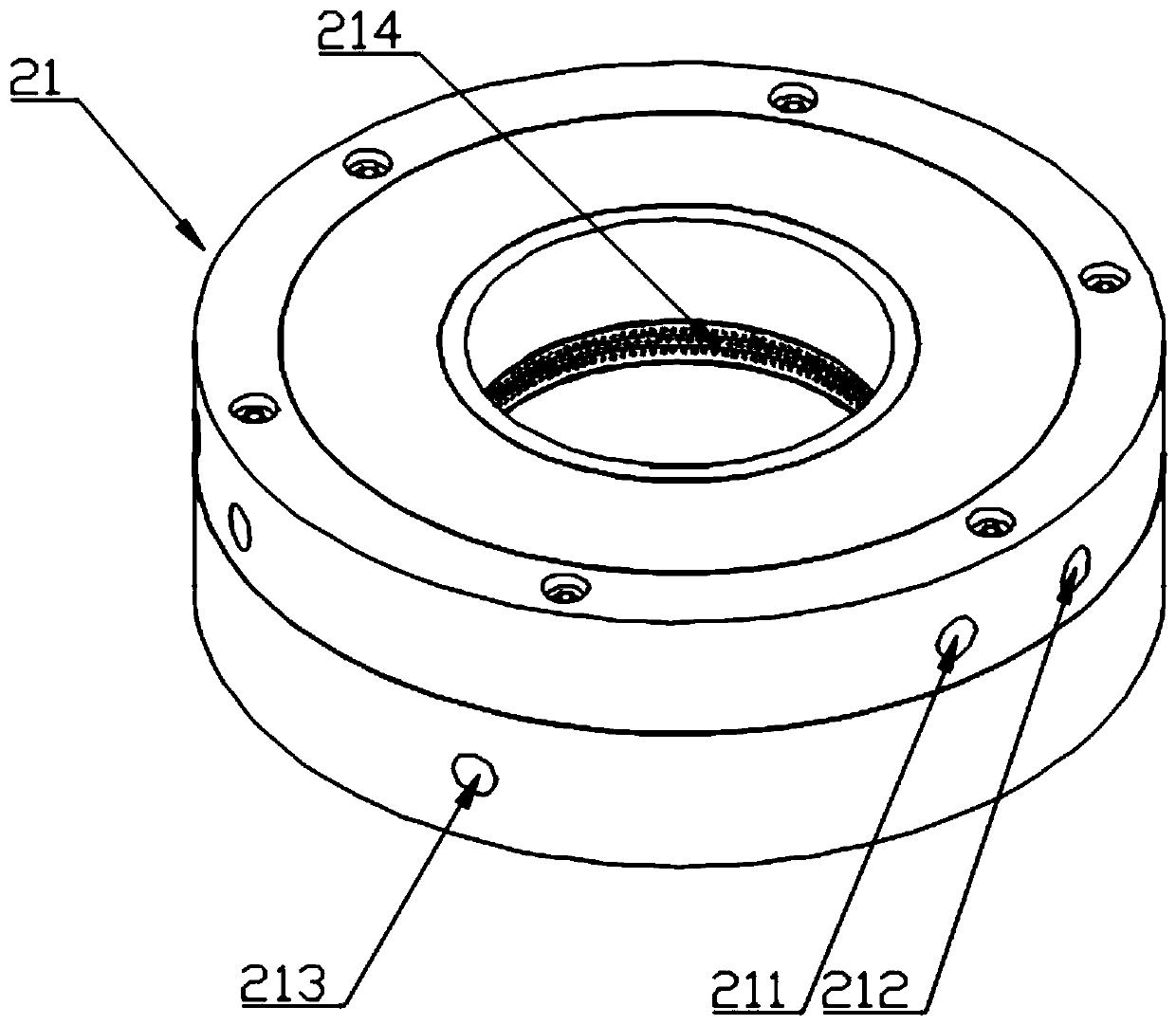

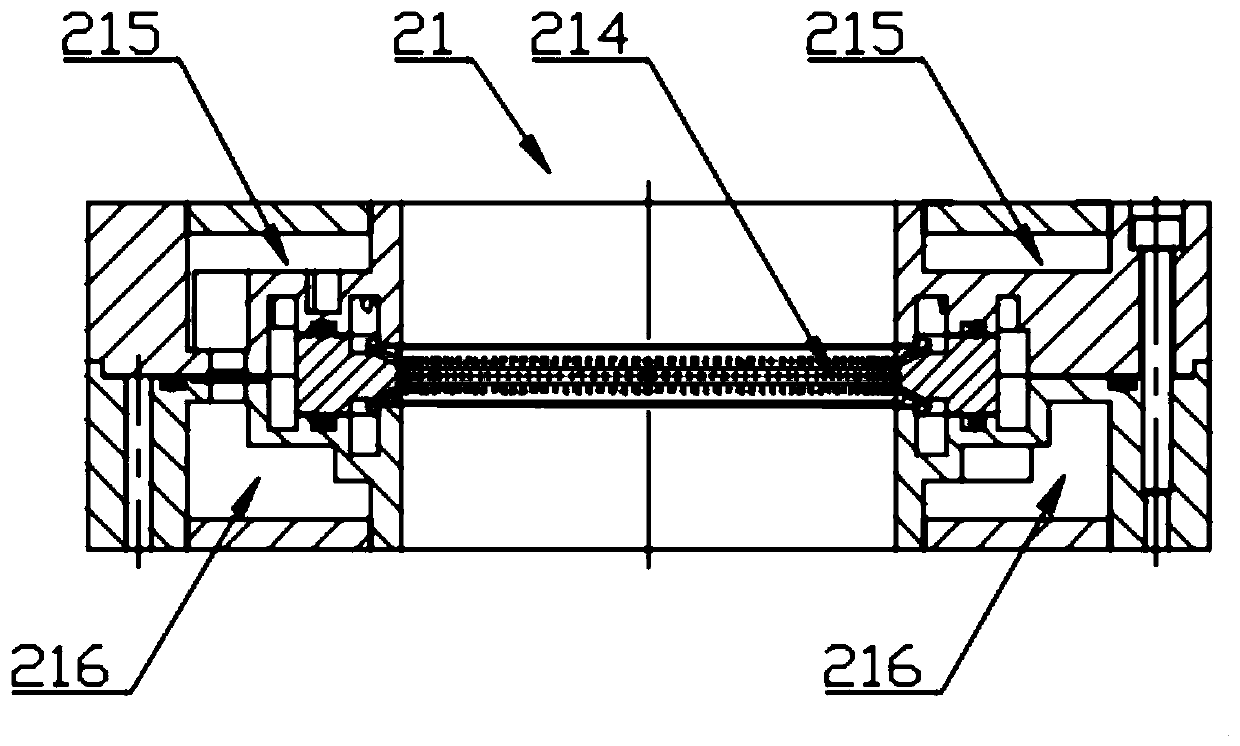

[0040] see figure 2 and image 3 As shown, the embodiment of the present invention provides a combustion-type optical fiber preform drawing equipment. Compared with Embodiment 1, the difference between this embodiment is that the annular blowtorch 21 is a circular structure and a hollow body, and the annular blowtorch 21 adopts Ablation-resistant metallic or ceramic materials. A hydrogen gas inlet 211 and an oxygen gas inlet 212 are provided on the outer wall of the annular blowtorch 21, and the diameters of the hydrogen gas inlet 211 and the oxygen gas inlet 212 are about 10 mm. A plurality of flame holes 214 are arranged on the inner wall of the annular torch 21, and the diameter of the flame holes 214 is about 0.6mm. A plurality of flame holes 214 are uniformly arranged in a ring along the inner wall of the annular torch 21 , and the specific number, arrangement and shape of the flame holes 214 can be specifically set according to actual needs.

[0041] A closed gas mix...

Embodiment 3

[0044] see figure 2 and image 3 As shown, the embodiment of the present invention provides a combustion-type optical fiber preform drawing equipment. Compared with Embodiment 2, the difference between this embodiment is that a process cooling water system is also provided in the ignition cabinet, and the process cooling water system The cooling water pipeline 10 is provided with a filter and a hand valve, the hand valve is used to control the flow of the cooling water pipeline 10 of the process cooling water system, and the filter is used to filter impurities in the cooling water. A water inlet 213 and a water outlet are also provided on the outer wall of the annular torch 21, and the water inlet 213 and the water outlet are far away from each other. A liquid cooling chamber 216 is provided between the outer wall and the inner wall of the annular blowtorch 21. The liquid cooling chamber 216 is an annular structure. The water pipeline 10 communicates, and the water outlet c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com