An iron-sulfur nutrient slow-release ball for sludge heavy metal bioleaching

A bioleaching and heavy metal technology, applied in the field of environmental pollution control, can solve the problems of easy precipitation of sulfur powder, loss with water, and difficulty in control, etc., to achieve the effect of enriching the total amount of nutrients, improving growth status, and increasing contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

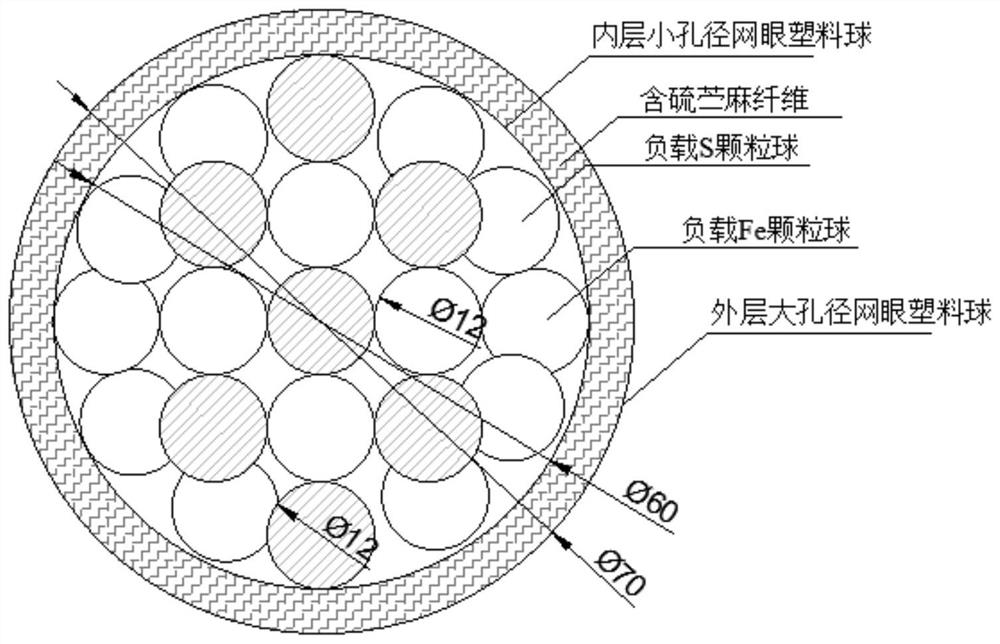

[0048] An iron-sulfur nutrient slow-release ball used for heavy metal bioleaching of sludge in the present invention:

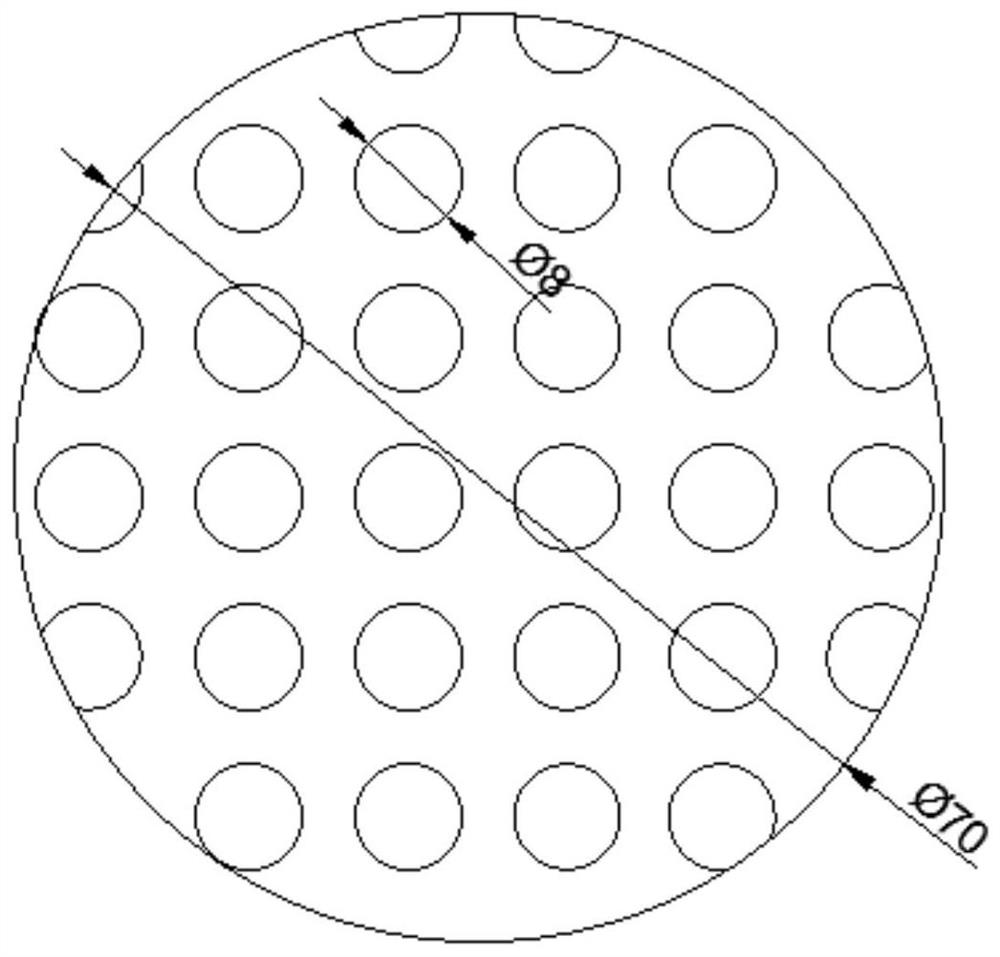

[0049] It consists of two parts: the inner part is a small particle ball loaded with iron-sulfur nutrition; the outer part is a plastic-fiber composite mesh large spherical shell; the inner small particle ball loaded with iron-sulfur nutrition is filled in the outer plastic-fiber composite mesh large spherical shell , together constitute iron-sulfur nutrient slow-release balls.

[0050] The small particle balls loaded with iron-sulfur nutrition are composed of two kinds of monomer particle balls uniformly mixed, which are respectively monomer-loaded Fe particle balls and monomer-loaded S particle balls; monomer-loaded Fe particle balls and monomer-loaded S particle balls The ratio of the number of small pellets loaded with iron-sulfur nutrition is 4:6; the dosage of small pellets loaded with iron-sulfur nutrients is 220 / m 3 ;The individual weight of small pe...

Embodiment 2

[0073] An iron-sulfur nutrient slow-release ball used for heavy metal bioleaching of sludge in the present invention:

[0074] It consists of two parts: the inner part is a small particle ball loaded with iron-sulfur nutrition; the outer part is a plastic-fiber composite mesh large spherical shell; the inner small particle ball loaded with iron-sulfur nutrition is filled in the outer plastic-fiber composite mesh large spherical shell , together constitute iron-sulfur nutrient slow-release balls.

[0075] Further, the small particle balls loaded with iron-sulfur nutrition are composed of two kinds of monomer particle balls, which are respectively monomer-loaded Fe particle balls and monomer-loaded S particle balls; monomer-loaded Fe particle balls and monomer-loaded The number ratio of S pellets is 4:6; the dosage of small pellets loaded with iron-sulfur nutrition is 260 / m 3 ;The individual weight of small pellets loaded with iron-sulfur nutrition is 20-26g;

[0076] The plas...

Embodiment 3

[0097] An iron-sulfur nutrient slow-release ball used for heavy metal bioleaching of sludge in the present invention:

[0098] It consists of two parts: the inner part is a small particle ball loaded with iron-sulfur nutrition; the outer part is a plastic-fiber composite mesh large spherical shell; the inner small particle ball loaded with iron-sulfur nutrition is filled in the outer plastic-fiber composite mesh large spherical shell , together constitute iron-sulfur nutrient slow-release balls.

[0099] Further, the small particle balls loaded with iron-sulfur nutrition are composed of two kinds of monomer particle balls, which are respectively monomer-loaded Fe particle balls and monomer-loaded S particle balls; monomer-loaded Fe particle balls and monomer-loaded The number ratio of S pellets is 4:6; the dosage of small pellets loaded with iron-sulfur nutrients is 240 / m 3 ;The individual weight of small pellets loaded with iron-sulfur nutrition is 20-26g;

[0100] The plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com