A filling device for sunscreen

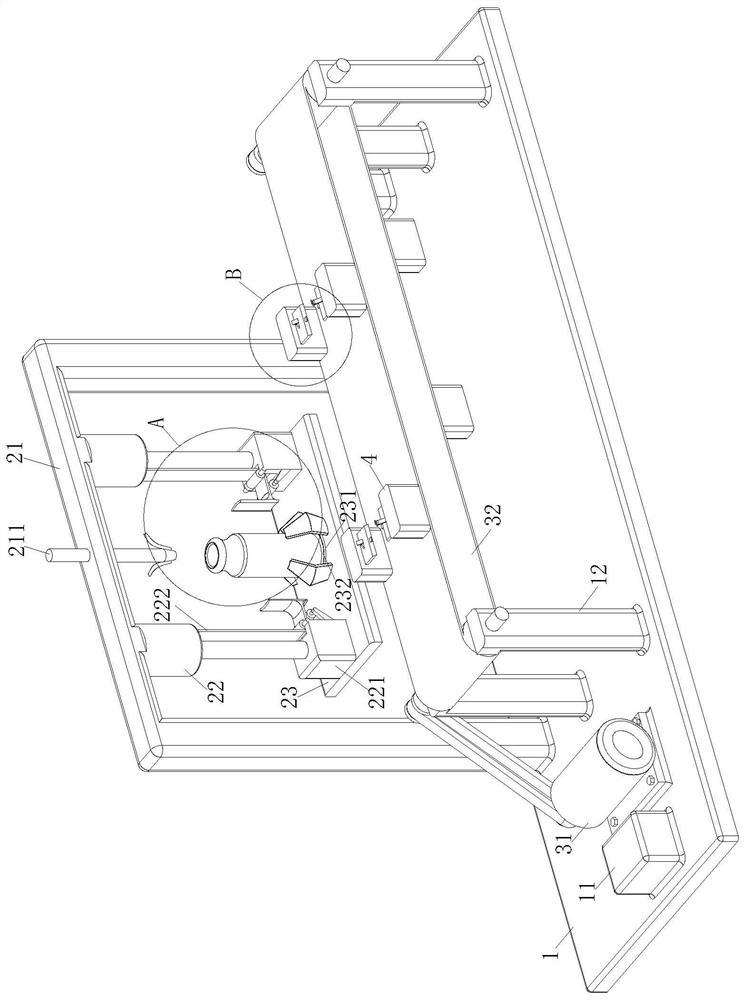

A filling device and sunscreen technology, applied in the field of sunscreen filling devices, can solve the problems of unstable bottling operation, material waste, bottling dumping, etc., and achieve the effects of reducing manual labor, maintaining stability, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

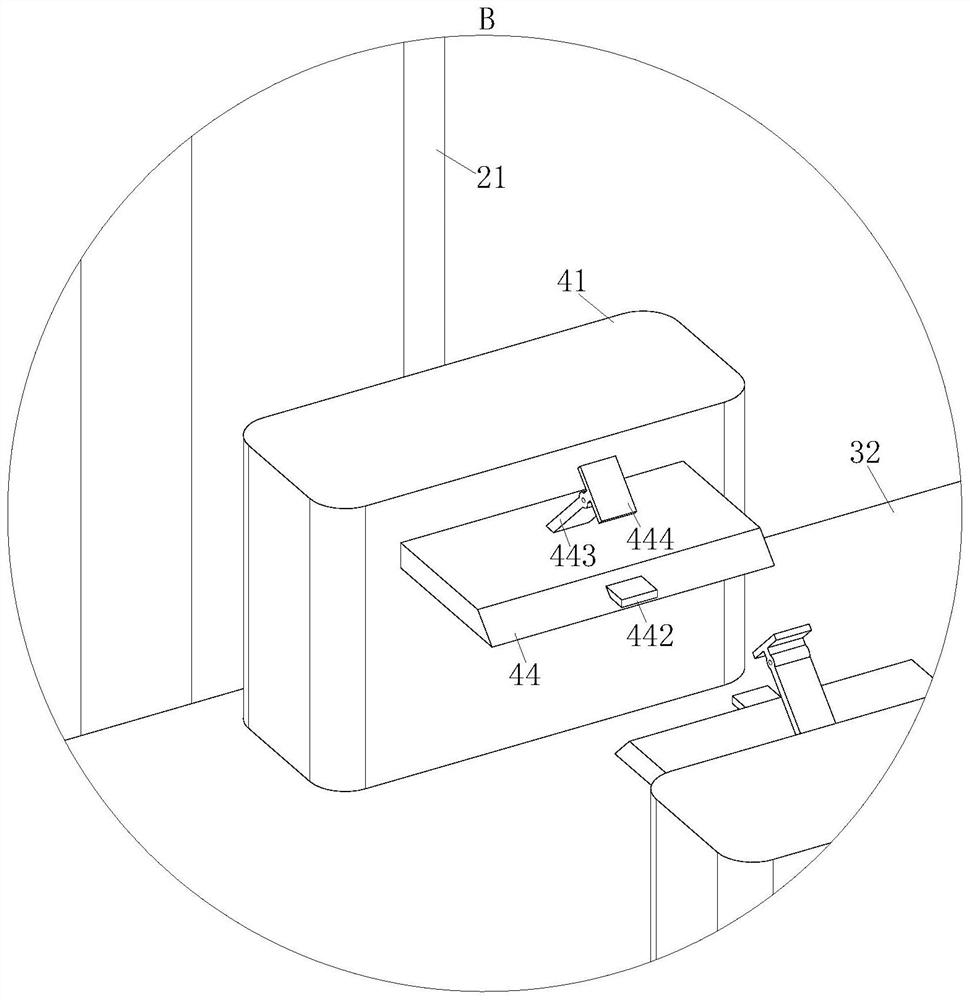

[0026] As an embodiment of the present invention, the stabilizing unit 4 includes a fixed block 41, a rotating rod 42, a torsion spring 43 and a splint 44; The hinged rotating rod 42 between the sides; the outer ring of the rotating rod 42 is sleeved with a splint 44; the splint 44 is connected to the two sides of the inner cavity of the fixed block 41 through a torsion spring 43; during work, the filled packaging bottle When 233 is placed between the two fixed blocks 41, under the action of the gravity of the packaging bottle 233, the lower end surface of the packaging bottle 233 presses the splint 44, and then the splint 44 rotates around the rotating rod 42. Under the torsion force of the torsion spring 43, the splint 44 tightly clamp the packaging bottle 233, so that the packaging bottle 233 is smoothly transmitted on the conveyor belt 32, avoiding the filling of the packaging bottle 233 topple over on the conveyor belt 32, and the compound plant essential oil sunscreen in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com