Method for corrected determination of frictional energy generated in a clutch during launch of a vehicle with a manual transmission

A manual transmission and clutch technology, applied to clutches, mechanical equipment, etc., can solve problems such as difficulties in determining frictional energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

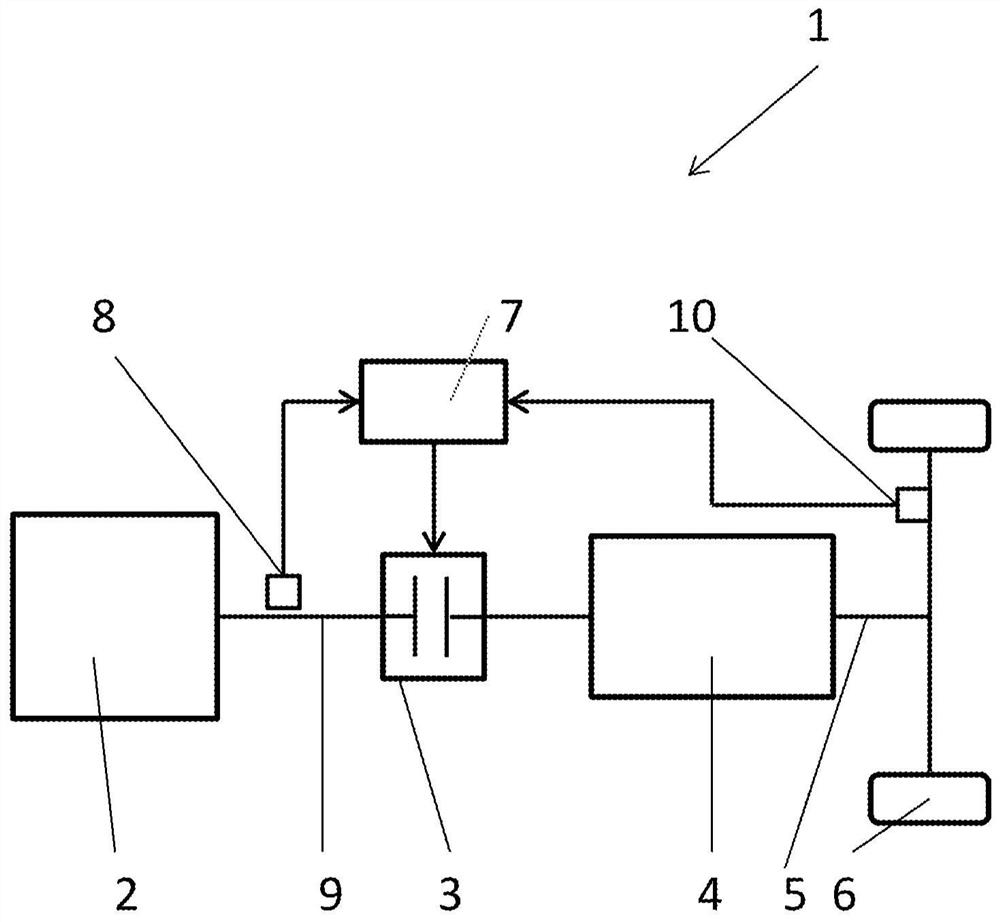

[0016] figure 1 A schematic schematic diagram of a drive train 1 of a vehicle is shown. The drive train 1 includes an internal combustion engine 2 and a clutch 3 for transmitting the torque provided by the internal combustion engine 2 . Here, the clutch 3 is connected to the transmission 4 , via which the torque generated by the internal combustion engine 2 is transmitted to the output shaft 5 and thus to the drive wheels 6 of the vehicle. The clutch 3 can be controlled here by means of a clutch controller 7 . The engine speed of the internal combustion engine 2 is measured by means of a rotational speed sensor 8 , which is located opposite a crankshaft 9 connected to the internal combustion engine 2 and the clutch 3 . Wheel speed sensor 10 determines the wheel speed effected by the transmitted drive torque. In this case, two rotational speed sensors 8 , 10 are connected to a clutch controller 9 .

[0017] Since there are no gear position and transmission speed sensors in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com