Core-spun yarn homogenizing device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

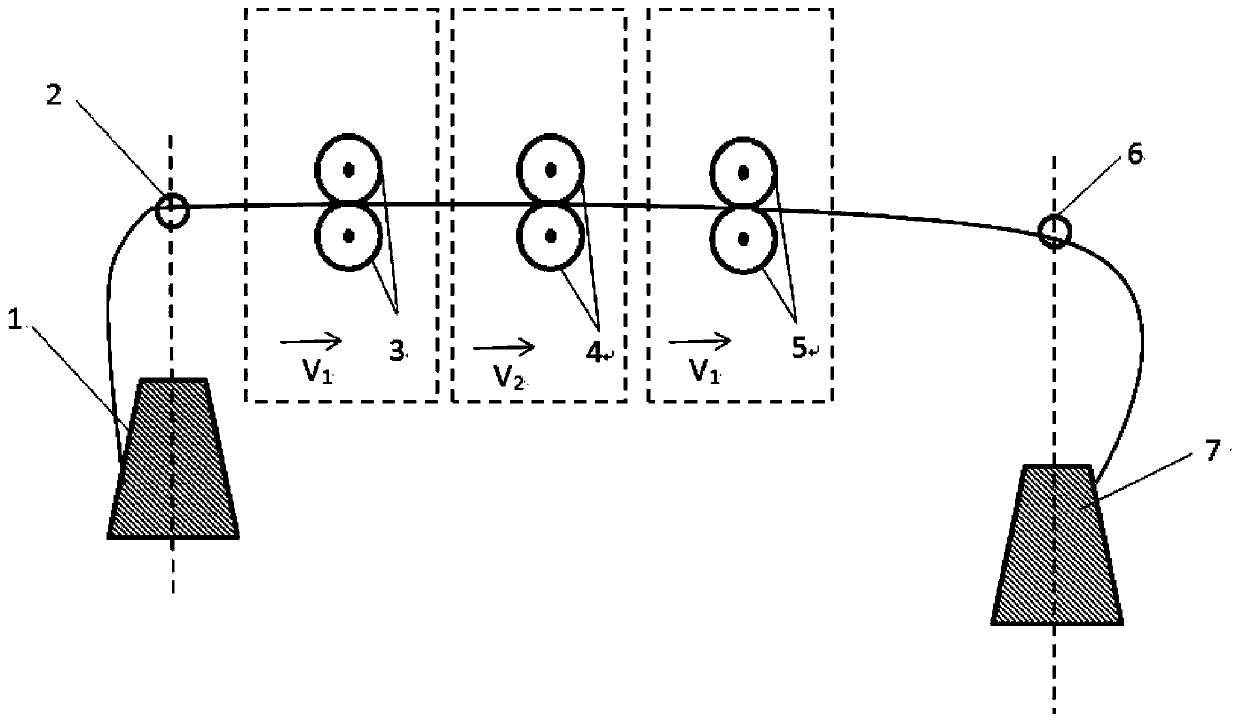

[0049] This embodiment provides a core-spun yarn leveling device, and the structural diagram of the device is as follows: figure 1 As shown, it includes sequentially connected yarn unwinding assembly, first roller 3, second roller 4, third roller 5 and yarn winding assembly.

[0050] The yarn unwinding assembly sequentially includes the yarn bobbin 1 to be adjusted and the first yarn guide ring 2; the centerlines of the yarn bobbin 1 to be adjusted and the first yarn guide ring 2 are located on the same vertical line; The distance between the upper end of the yarn bobbin 1 and the first yarn guide ring 2 is twice the maximum diameter of the upper end of the yarn bobbin 1 to be adjusted.

[0051] The first roller 3 , the second roller 4 and the third roller 3 independently include upper rollers and lower rollers; the lower rollers are actively driven, and the upper rollers are passively driven.

[0052] The linear velocity of the second roller 4 is greater than the linear velo...

Embodiment 2

[0055] This embodiment provides a core-spun yarn leveling device, which includes a yarn unwinding assembly, a first roller 3, a second roller 4, a third roller 5 and a yarn winding assembly connected in sequence.

[0056] The yarn unwinding assembly sequentially includes the yarn bobbin 1 to be adjusted and the first yarn guide ring 2; the centerlines of the yarn bobbin 1 to be adjusted and the first yarn guide ring 2 are located on the same vertical line; The distance between the upper end of the yarn bobbin 1 and the first yarn guide ring 2 is 1.5 times the maximum diameter of the upper end of the yarn bobbin 1 to be adjusted.

[0057] The first roller 3 , the second roller 4 and the third roller 3 independently include upper rollers and lower rollers; the lower rollers are actively driven, and the upper rollers are driven passively.

[0058] The linear velocity of the second roller 4 is greater than the linear velocity of the first roller 3 and the third roller 5, and the l...

Embodiment 3

[0061] This embodiment provides a core-spun yarn leveling device, which includes a yarn unwinding assembly, a first roller 3, a second roller 4, a third roller 5 and a yarn winding assembly connected in sequence.

[0062] The yarn unwinding assembly sequentially includes the yarn bobbin 1 to be adjusted and the first yarn guide ring 2; the centerlines of the yarn bobbin 1 to be adjusted and the first yarn guide ring 2 are located on the same vertical line; The distance between the upper end of the yarn bobbin 1 and the first yarn guide ring 2 is twice the maximum diameter of the lower end of the yarn bobbin 1 to be adjusted.

[0063] The first roller 3 , the second roller 4 and the third roller 3 independently include upper rollers and lower rollers; the lower rollers are actively driven, and the upper rollers are driven passively.

[0064] The linear velocity of the second roller 4 is greater than the linear velocity of the first roller 3 and the third roller 5, and the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com