A diaphragm-free electrochemical lithium extraction system and lithium extraction method thereof

An electrochemical, non-diaphragm technology, applied in the direction of improving process efficiency, can solve the problems of inability to achieve lithium extraction operation, high energy consumption, low extraction efficiency, etc., and achieve easy automatic operation, efficient separation and enrichment, structure and Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

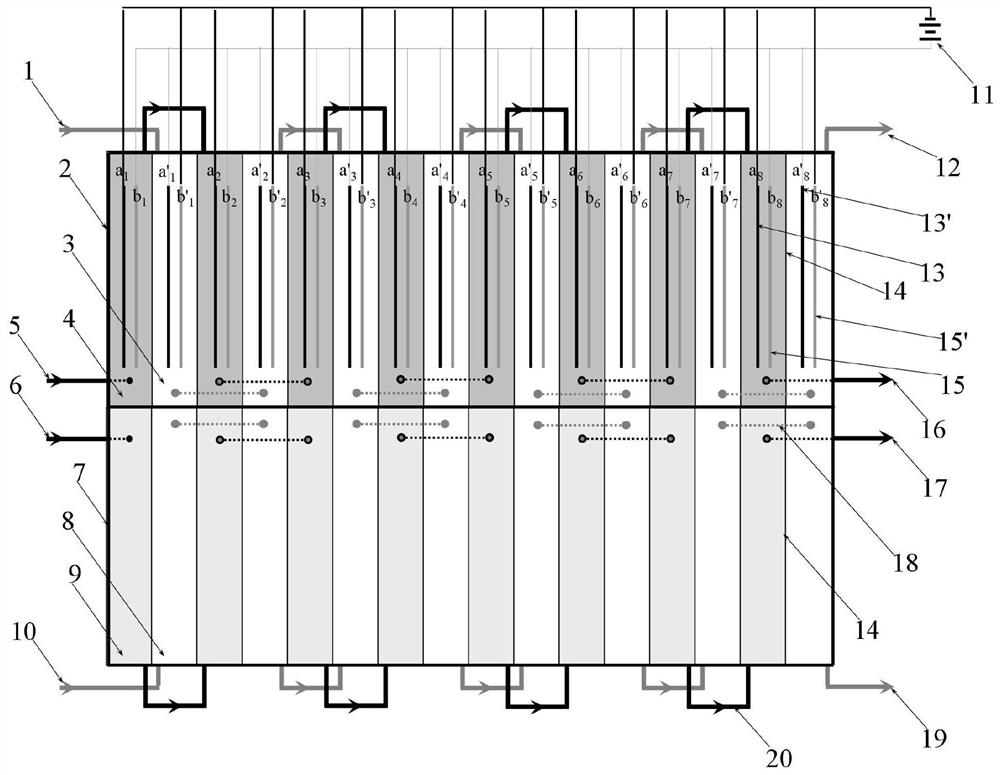

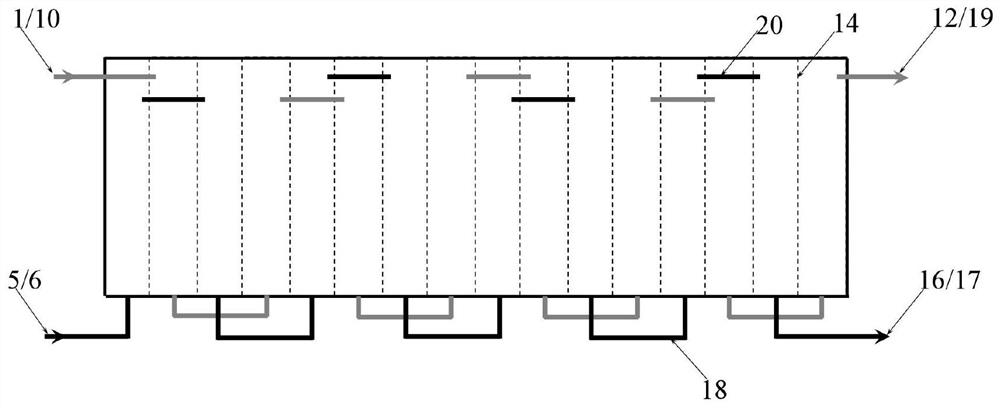

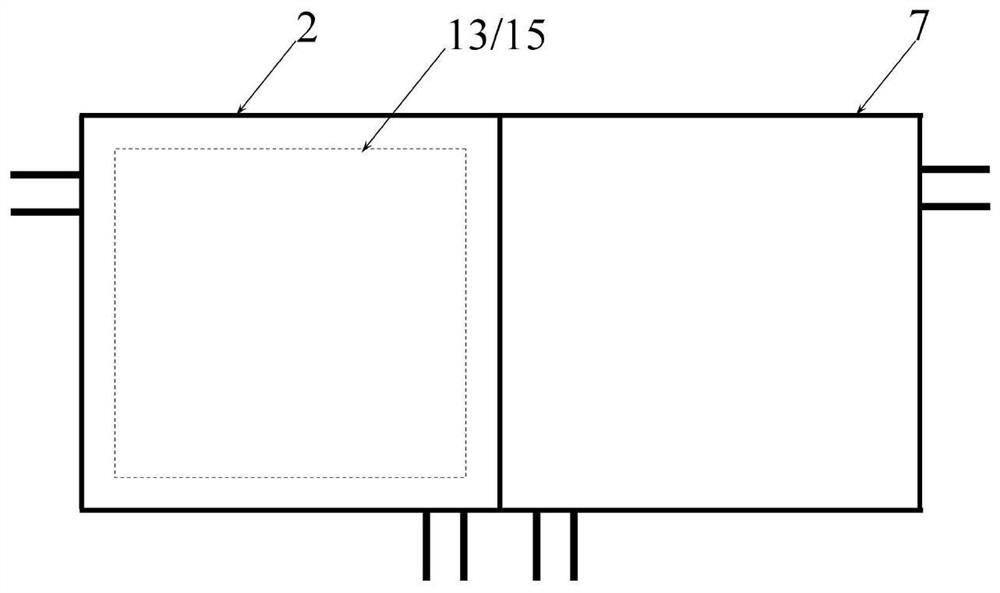

[0028] An electrode reciprocating lithium extraction system without diaphragm, which can realize eight-stage extraction, see Figure 1~3 , the system includes an electrolytic tank 2, a washing tank 7, a power supply 11, a plurality of lithium-absorbing electrodes 13, a plurality of lithium-removing electrodes 13', a plurality of electron-losing balance electrodes 15, and a plurality of electron-gaining balance electrodes 15'. The electrolytic tank is arranged side by side with the washing tank. A plurality of separators 14 are installed in the electrolytic cell at intervals in parallel, and the separator divides the electrolytic cell into a plurality of raw material pools 4 and a plurality of recovery pools 3, the raw material pools and the recovery pools are arranged alternately, and the multiple raw material pools are connected in series through connecting pipes , multiple recovery tanks are connected in series through connecting pipes. Install a lithium absorbing electrode...

Embodiment 2

[0035] An electrode circulation type lithium extraction system without a diaphragm, which can realize eight-stage lithium extraction. The main difference between this device and the device in Example 1 is that there is no washing tank, but two washing tanks are set at both ends of the electrolytic tank. The cell electrode washing cell washes the electrodes in the raw material cell, and the recovery cell electrode cleaning cell washes the electrodes in the recovery cell.

[0036] The plurality of lithium-absorbing electrodes, the plurality of lithium-removing electrodes, the plurality of electron-losing balance electrodes, and the plurality of electron-gaining balance electrodes are connected to a circulation type lithium extraction device, and the circulation type lithium extraction device is programmed so that the electrodes are separated between the electrolytic cell and the Reciprocating movement between washing pools.

[0037] The specific electrode cycle movement mode is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com