Cam drilling tool suitable for multi-aperture cams

A drilling tool and multi-aperture technology, which is applied in the direction of drilling templates, positioning devices, manufacturing tools, etc. for workpieces, can solve the problem that the drilling accuracy is greatly affected by the technical level and experience of workers, the product quality is difficult to guarantee, and the resource consumption is low. Major problems, to achieve the effect of improving drilling efficiency, saving resources and avoiding resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

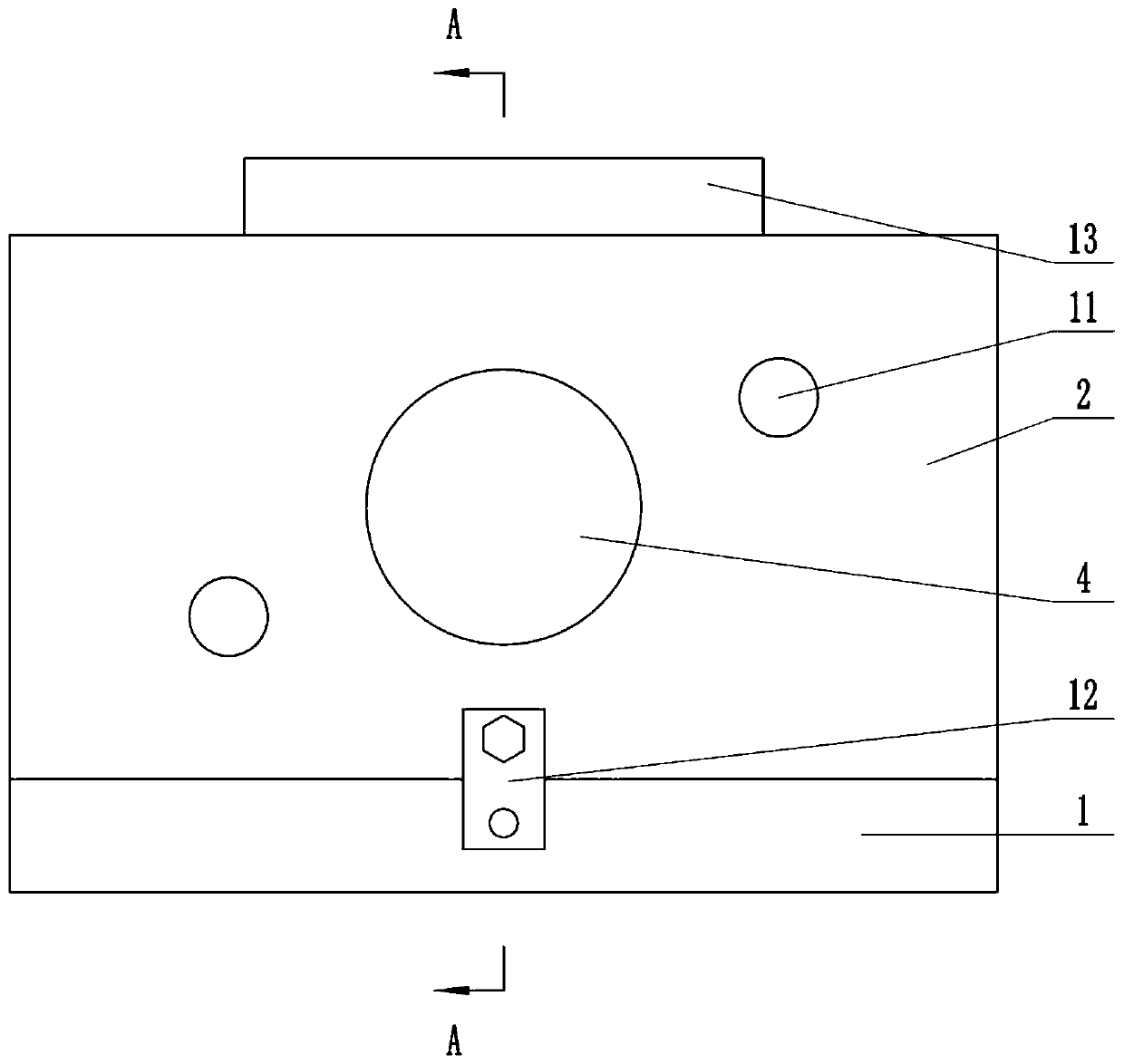

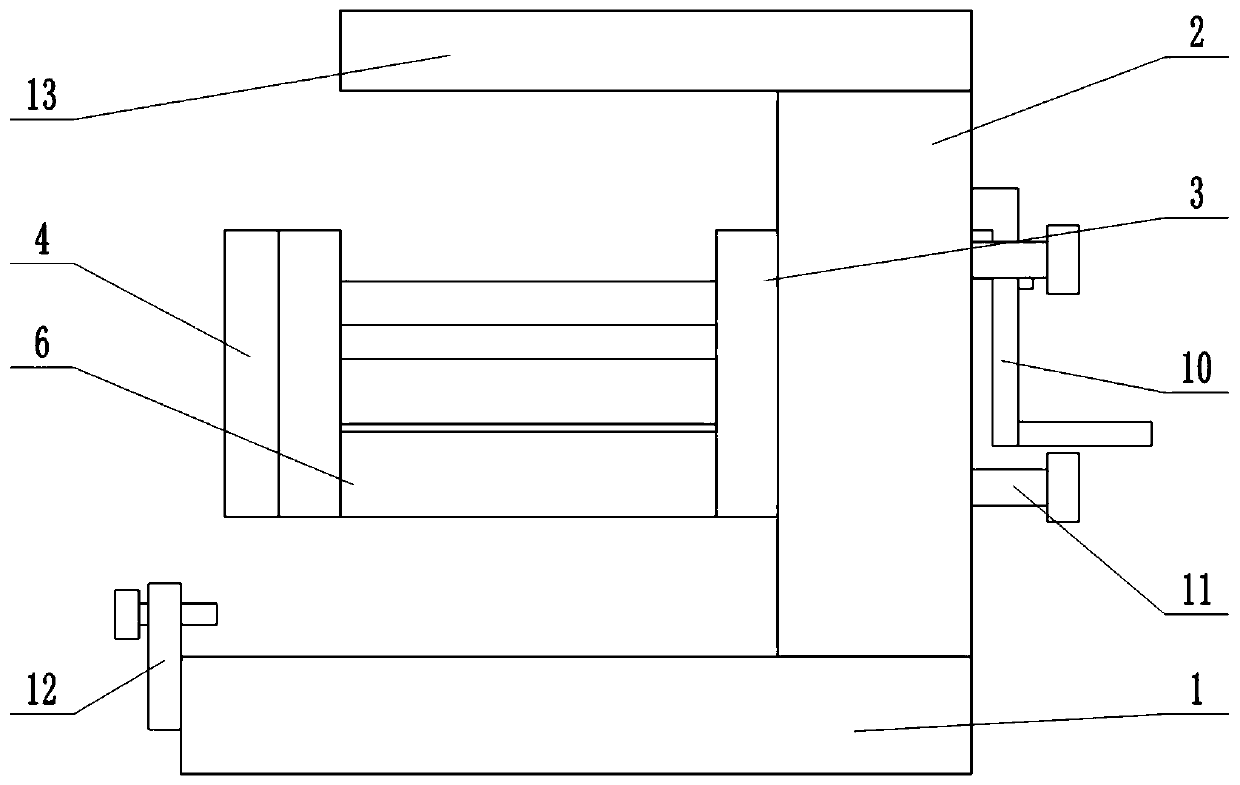

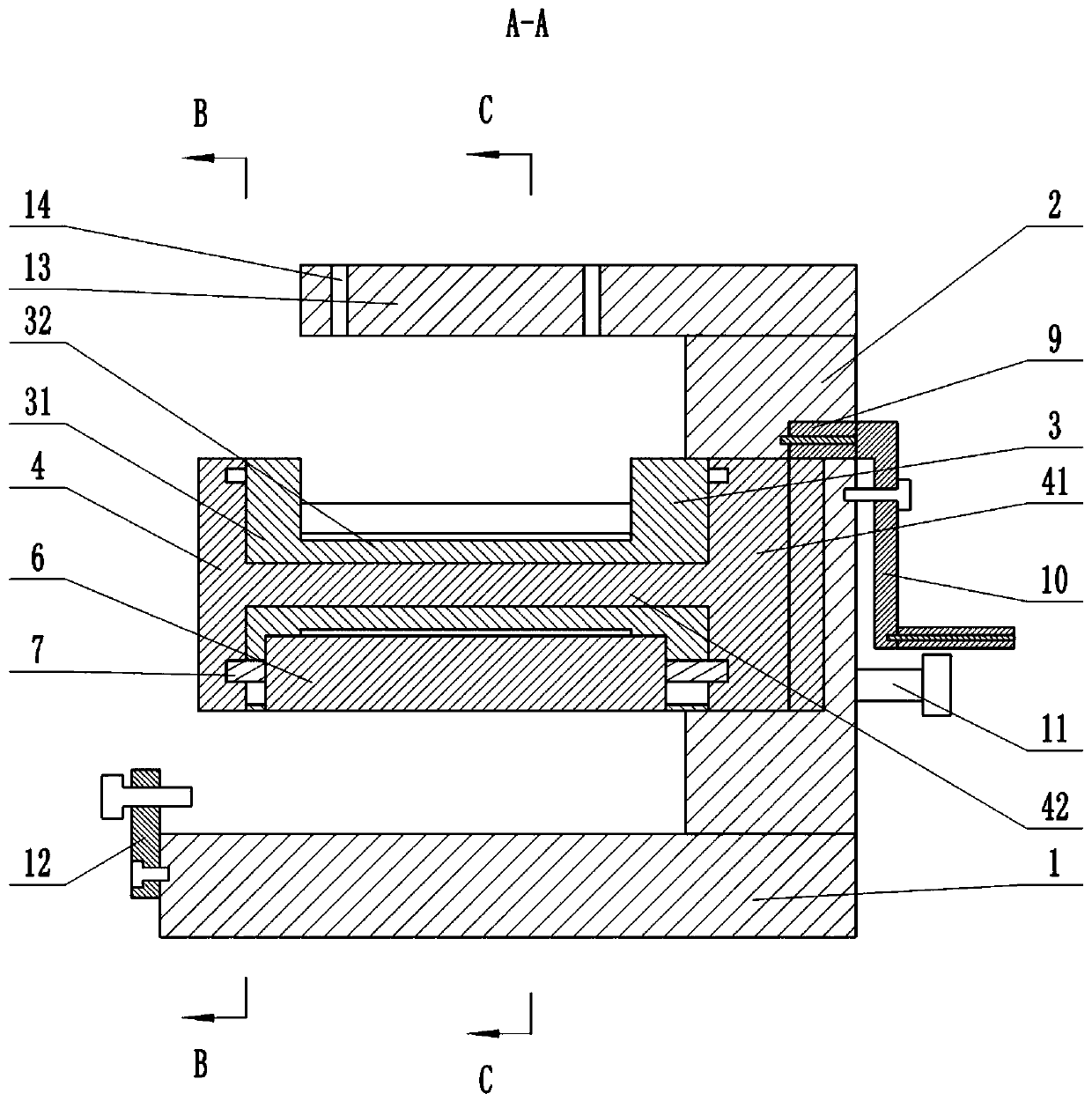

[0039] A cam drilling tool suitable for multi-diameter cams, comprising a bottom plate 1, a vertical support plate 2 is fixed on one side of the top of the bottom plate 1, and a camshaft hole with adjustable support aperture is fixed in the middle of one side of the vertical support plate 2 The support device, the camshaft hole support device is located directly above the bottom plate 1, and the side of the vertical support plate 2 is provided with a handle 10 for adjusting the support radius of the camshaft hole support device,

[0040] The vertical support plate 2 is horizontally provided with several support bolts 11, the side wall of the base plate 1 away from the vertical support plate 2 is provided with a cam locking device 12, and the top of the vertical support plate 2 is fixed with a horizontal support plate 13, The horizontal support plate 13 is positioned directly above the camshaft hole support device, and the horizontal support plate 13 vertically passes through an...

Embodiment 2

[0048] A cam drilling tool suitable for multi-diameter cams, comprising a bottom plate 1, a vertical support plate 2 is fixed on one side of the top of the bottom plate 1, and a camshaft hole with adjustable support aperture is fixed in the middle of one side of the vertical support plate 2 The support device, the camshaft hole support device is located directly above the bottom plate 1, and the side of the vertical support plate 2 is provided with a handle 10 for adjusting the support radius of the camshaft hole support device,

[0049] The vertical support plate 2 is horizontally provided with several support bolts 11, the side wall of the base plate 1 away from the vertical support plate 2 is provided with a cam locking device 12, and the top of the vertical support plate 2 is fixed with a horizontal support plate 13, The horizontal support plate 13 is positioned directly above the camshaft hole support device, and the horizontal support plate 13 vertically passes through an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap