Handheld dust collector separation method for separating dust cup assembly by one key

A separation method and vacuum cleaner technology, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of shaking dust cups, easy gaps at joints, and affecting the firmness of dust cup components, so as to achieve convenient disassembly and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

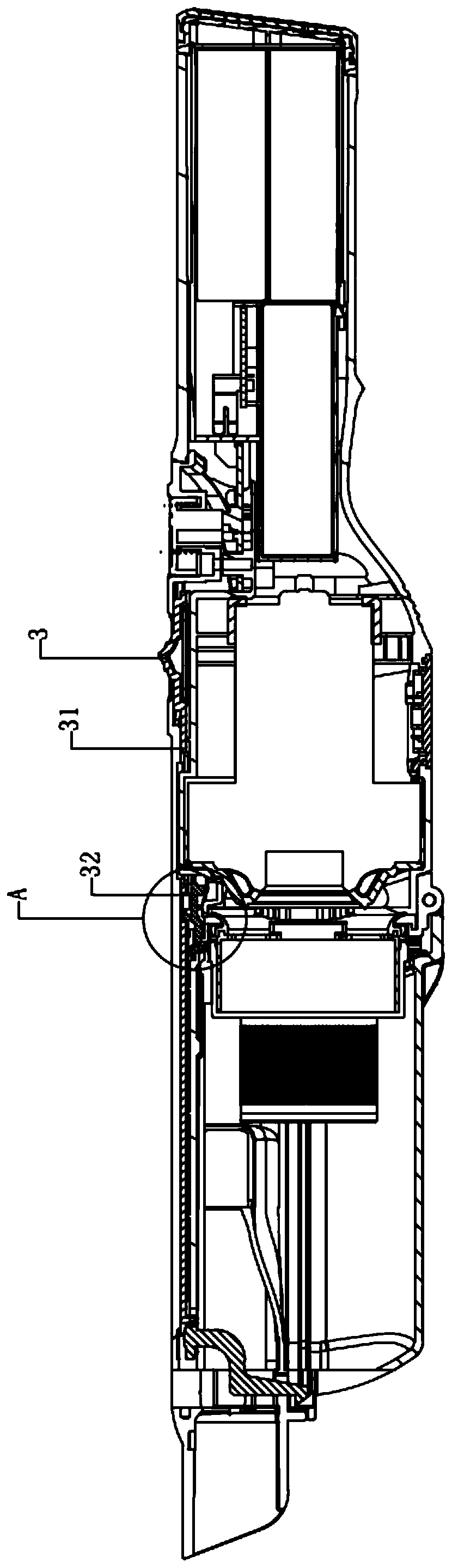

[0031] see Figure 1 to Figure 5 , the figure shows a hand-held vacuum cleaner with one-button separation of the dust cup assembly provided by the embodiment of the present invention, which includes a vacuum cleaner main body 1 and a dust cup assembly 2, and the first end 11 of the vacuum cleaner main body 1 extends outward to form a grip handle 12. The opposite second end 13 extends outward to form a dust cup connecting portion 14, which extends outward along the axial direction of the vacuum cleaner main body 1, and has a first slide rail 141 on the dust cup connecting portion 14, the first The slide rail 141 is arranged along the length direction of the dust cup connecting portion 14, and the second slide rail 21 is arranged on the dust cup assembly 2, and the second slide rail 21 is arranged along the axial direction of the dust cup assembly 2. The second slide rail 21 is inserted into the first slide rail 141 along the length direction of the first slide rail 141 , or the...

Embodiment 2

[0038] see Figure 1 to Figure 5 , the figure shows a hand-held vacuum cleaner with one-button separation of the dust cup assembly provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the locking hook 32 has a driven end 321 and a hook end 322, which are integrally formed between the driven end 321 and the hook end 322, the end of the driving rod 31 pushes or pulls the driven end 321, and the hook end 322 hooks the clamping part 22; specifically , the cross-section of the driven end 321 is L-shaped, the cross-section of the hook end 322 is U-shaped, and the bottom has a hook body 3221 . Through the arrangement of the above structure, it can be ensured that the lock hook is firmly hooked to the dust cup assembly, and the decoupling of the lock hook is facilitated.

Embodiment 3

[0040] see Figure 1 to Figure 5 , the figure shows a hand-held vacuum cleaner with one-button separation of the dust cup assembly provided by Embodiment 3 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: dust cup The assembly 2 includes a dust cup 23 and an air duct 24, and the filter member 25 is detachably inserted into the dust cup 23 from an assembly hole provided on the inner end of the dust cup 23, and the dust cup 23 includes any plane in the height direction of the dust cup 23 The cup body 231 and the cup cover 232 as the dividing surface, the cup body 231 covers at least two sides of the dust cup 23, the cup cover 232 covers at least two sides of the dust cup 23, and the air duct 24 is integrated on the outer end of the cup body 231 , and the air inlet 241 of the air duct 24 extends outward from the outer end of the cup body 231 , and the air outlet 242 of the air duct 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com