Rough and fine adjustment needle switch

A technology of coarse and fine adjustment and coarse adjustment, which is applied in the field of coarse and fine adjustment needle switches, which can solve the problems of inability to adjust the oil pressure and flow in a small range, and poor sealing, and achieve the effects of precise adjustment, improved sealing, and improved adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

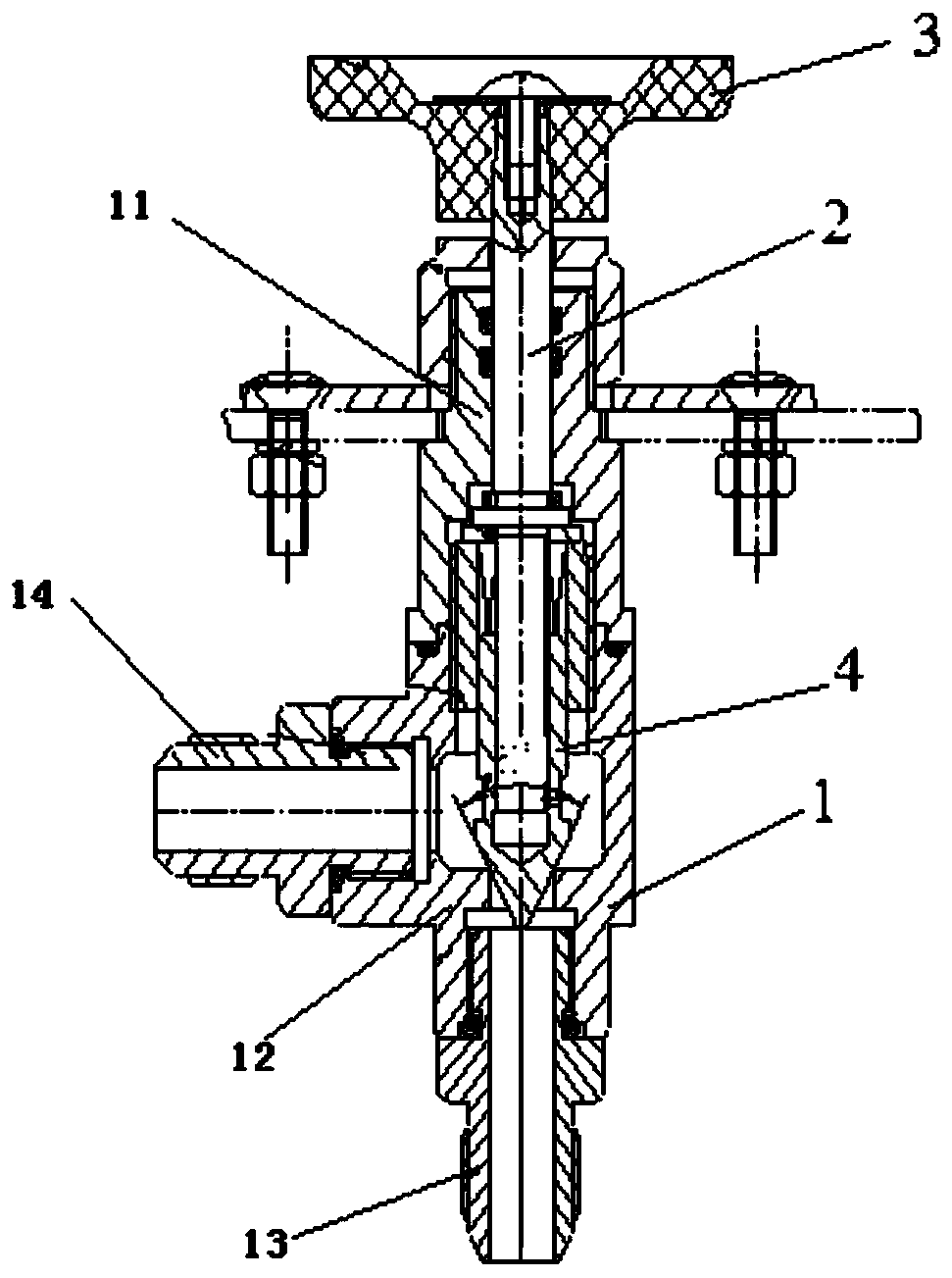

[0058] The structure of a coarse and fine adjustment needle switch of the present invention is as follows:

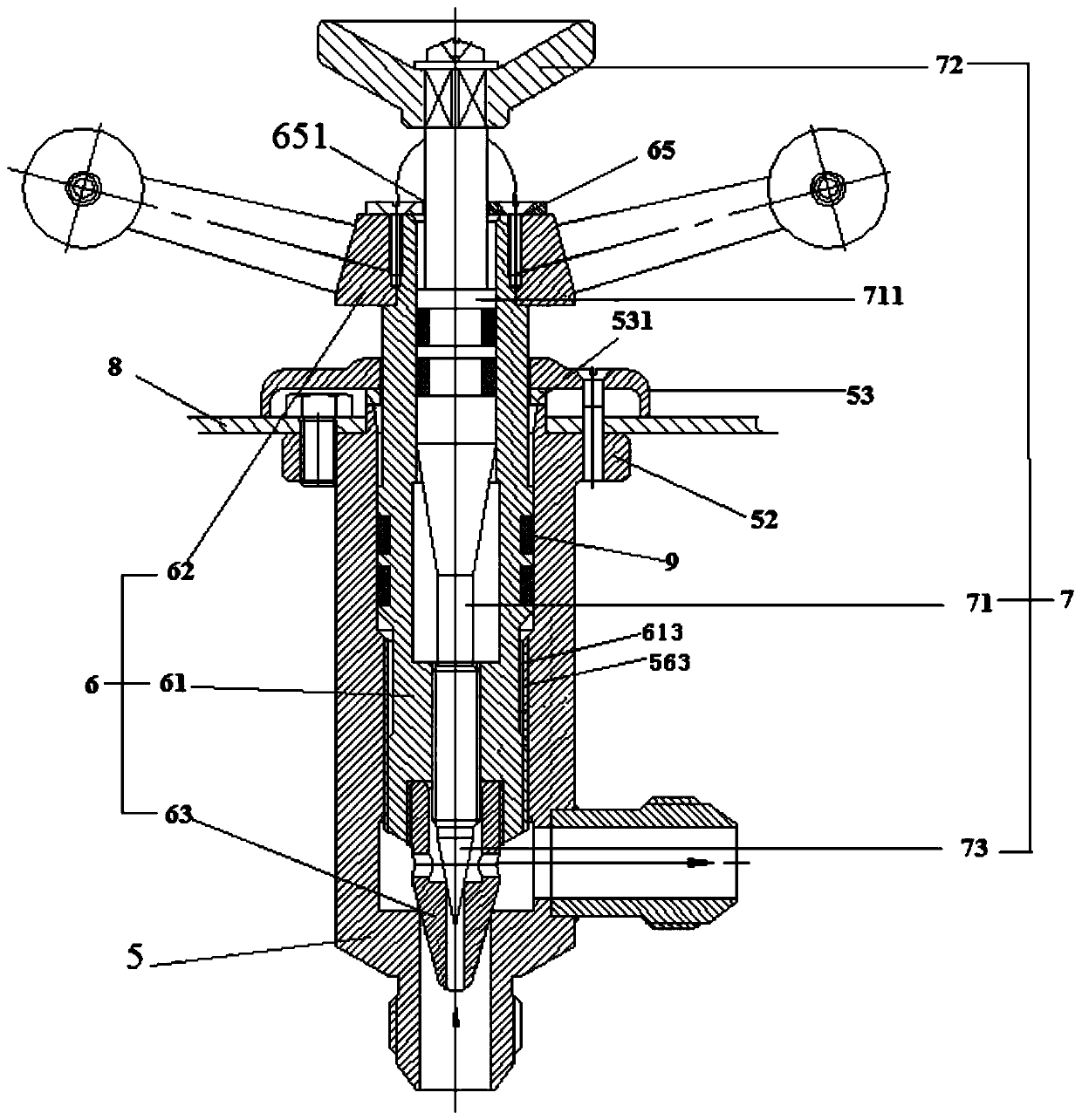

[0059] Such as figure 2 As shown, it includes valve body 5, coarse adjustment assembly 6 and fine adjustment assembly 7;

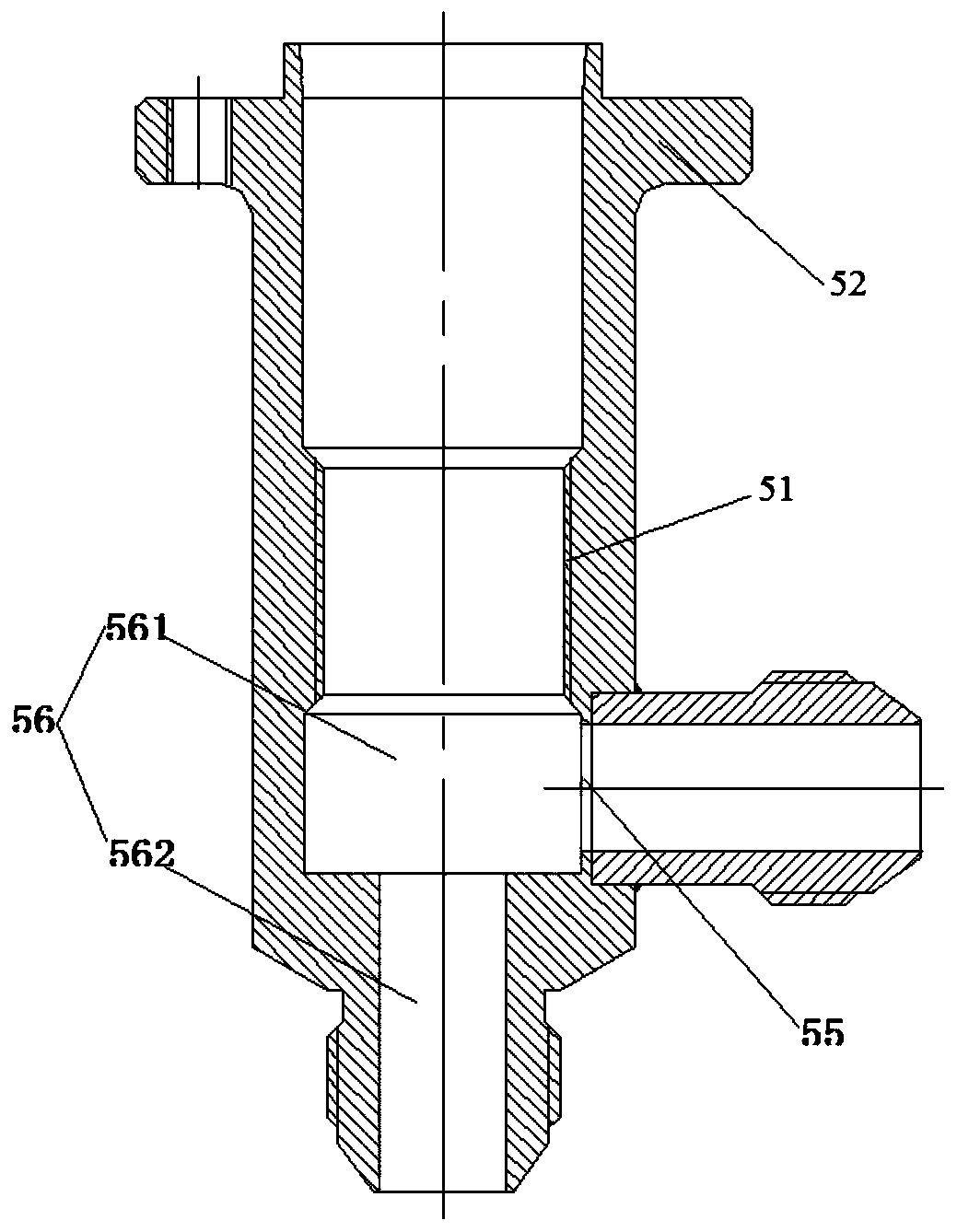

[0060] Such as image 3 As shown, the valve body 5 is provided with a coarse adjustment step hole 56, and the coarse adjustment step hole 56 includes a coarse adjustment large hole 561 and a coarse adjustment small hole 562, and the coarse adjustment small hole 562 is the oil inlet hole of the valve body; the side of the valve body 5 The valve body oil outlet hole 55 communicated with the large coarse adjustment hole 561 is arranged on the wall; the valve body 5 is connected with the mounting plate 8 through the flange 52 provided on its upper end, and the valve body 5 has an integrated structure.

[0061] The coarse adjustment assembly 6 includes a coarse adjustment valve stem 61, a coarse adjustment handle 62 and a coarse adjustment taper plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com