An installation and fixing device for a transmission line tower holding a pole

A technology for fixing devices and pole towers, applied in towers, building types, buildings, etc., can solve the problems of unstable pole-mounted fixed structure and small application range, so as to improve the reliability of equipment operation, increase construction efficiency, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

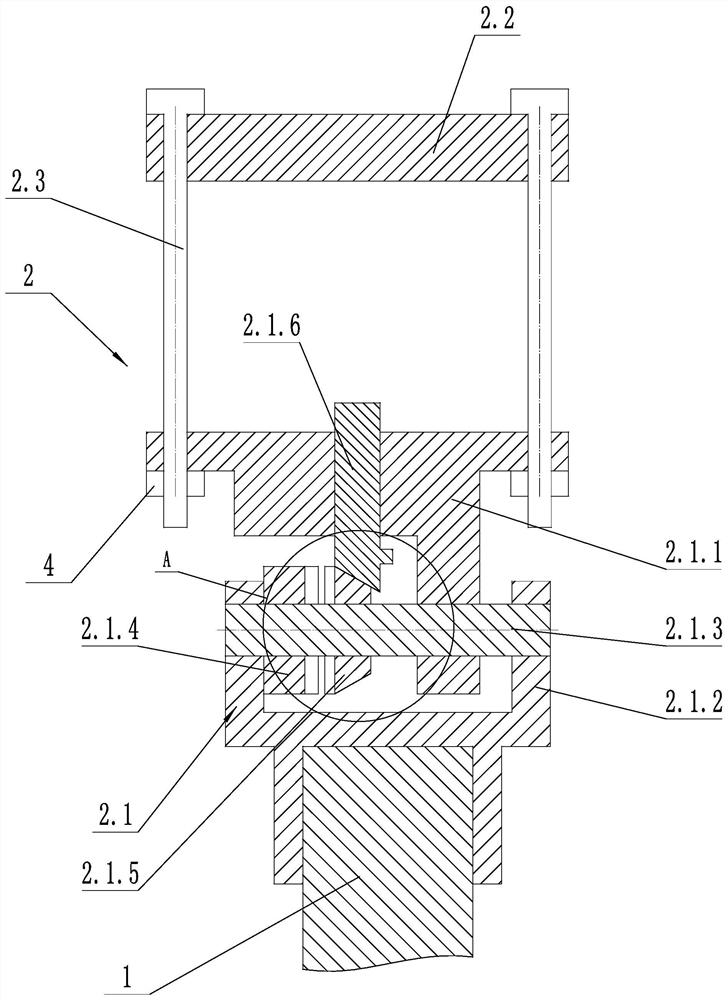

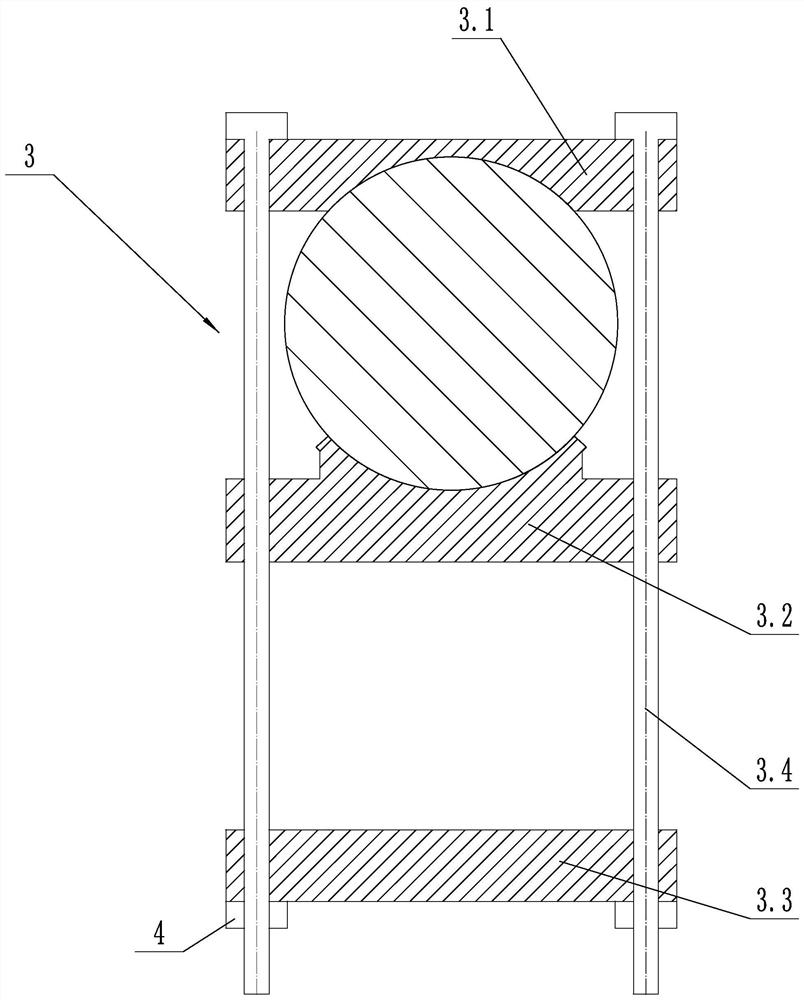

[0026] Such as figure 1 and figure 2 As shown in the figure, a transmission line tower holding pole installation and fixing device includes a holding pole 1, an end fixing part 2 and an intermediate fixing part 3, and the end fixing part 2 includes a connecting part 2.1, a fastener 2.2 and a first fastening screw 2.3; the end of the holding rod 1 is fixed with the connecting piece 2.1; one end of the first fastening screw 2.3 presses the fastening piece 2.2, and the other end of the first fastening screw 2.3 passes through the connecting piece 2.1 and is pressed and connected by the nut 4 2.1 is fixed; the end fixture 2 is provided with a friction pad, and the friction pad is arranged on the surface of the end fixture 2 in contact with the clamped object; the middle fixture 3 includes the first clamping piece 3.1, the middle support piece 3.2. The second clamping part 3.3 and the second fastening screw 3.4, the intermediate support part 3.2 is arranged between the first clam...

Embodiment 2

[0029] Such as figure 1 As shown, on the basis of Embodiment 1, the connecting member 2.1 includes a rotating part 2.1.1, a supporting part 2.1.2, a rotating shaft 2.1.3, a first toothed disc 2.1.4, a second toothed disc 2.1.5 and The locking rod 2.1.6, the rotating part 2.1.1 is fixed to the rotating shaft 2.1.3, the rotating shaft 2.1.3 is connected to the supporting part 2.1.2 in rotation, and the first gear plate 2.1.4 is arranged coaxially with the rotating shaft 2.1.3 and is connected to the support Component 2.1.2 is fixed, the second toothed disc 2.1.5 is coaxially arranged with the rotating shaft 2.1.3, and the second toothed disc 2.1.5 and the rotating shaft 2.1.3 are slidably connected through a spline structure, and the second toothed disc 2.1.5 The sliding direction is parallel to the axis of the rotating shaft 2.1.3; the locking rod 2.1.6 is telescopically connected to the rotating part 2.1.1, and one end of the locking rod 2.1.6 is in contact with the second too...

Embodiment 3

[0032] Such as image 3 As shown, on the basis of Embodiment 2, the locking rod 2.1.6 and the rotating part 2.1.1 are connected through a threaded connection to realize telescopic connection, and the telescopic direction of the locking rod 2.1.6 is the same as that of the second chainring 2.1.5 parallel to the sliding direction. The above-mentioned structure connects the locking rod 2.1.6 with the rotating part 2.1.1 through threaded connection, and the locking rod 2.1.6 can be expanded and contracted by rotating the locking rod 2.1.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com