Steel rail temporary fixing structure and longitudinal blocking groove block installation and construction method

A temporary fixing and rail technology, applied in the directions of track, track laying, track maintenance, etc., can solve the problems of difficulty in initial commissioning, maintenance and replacement of rails, poor contact between wheels and rails, and large rail wear. Longevity, the effect of improving the contact relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

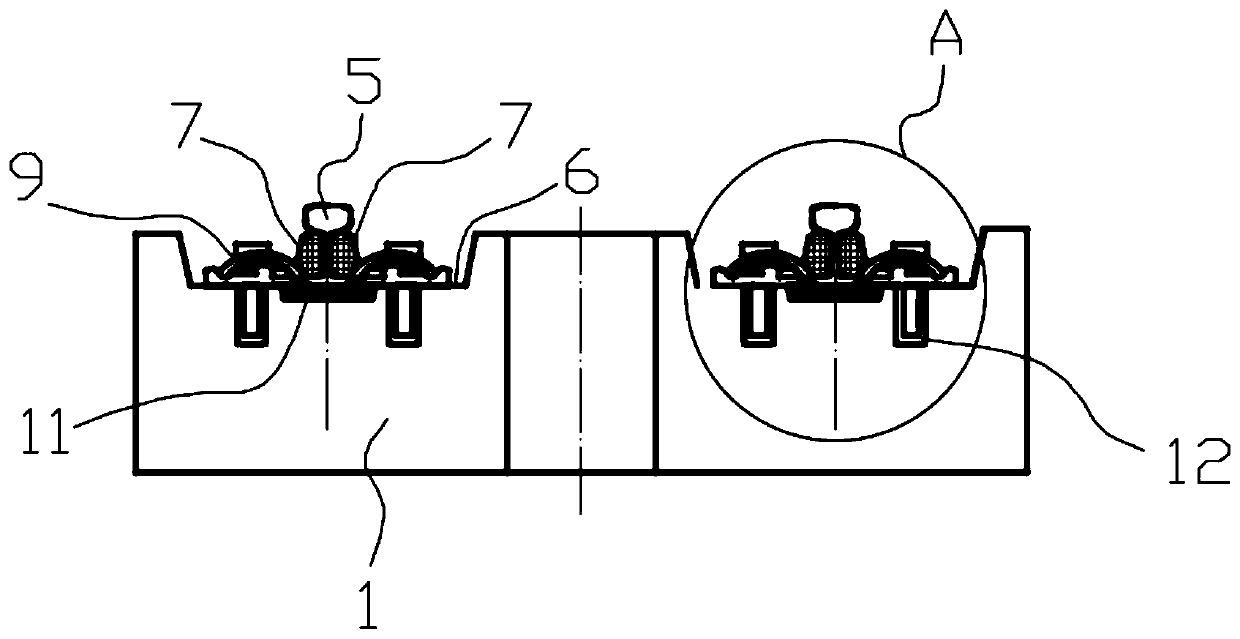

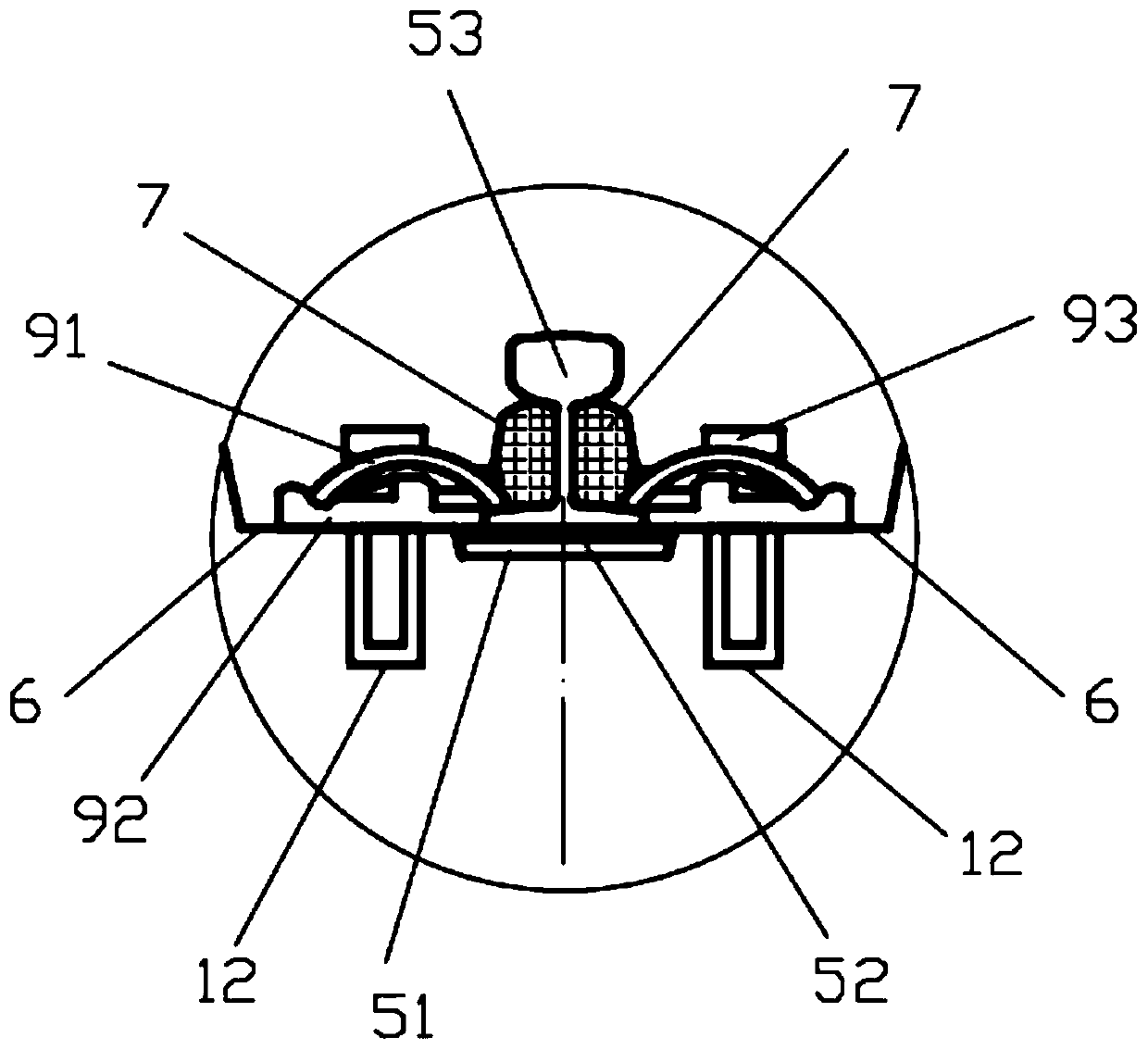

[0033] Such as figure 1 , 2 As shown, the rail temporary fixing structure disclosed in the first embodiment includes a plate body 1, a rail assembly 5 and a temporary fastener 9. There are two longitudinal grooves 4 on the top surface of the plate body 1, and the groove bottom of each longitudinal groove 4 There is a concave rail bearing groove 11 formed in the center. The rail assembly 5 includes a rail 53, which is placed in the rail bearing groove 11, and the rail 53 is fixed on the plate body 1 through a plurality of temporary fasteners 9, and bolt sleeves 12 are pre-embedded on the steps 6 on both sides of the rail bearing groove 11 , the temporary fastener 9 is bolted to the plate body 1.

[0034] The rail assembly 5 also includes a height-adjusting backing plate 52 and a long elastic backing plate 51, the long elastic backing plate 51 is spread on the bottom of the rail groove 11, the rail 53 is pressed on the height-adjusting backing plate 52, and the height-adjustin...

Embodiment 2

[0046]The difference between this embodiment and Embodiment 1 is that: Figure 7 As shown, in this embodiment, the longitudinal groove 4 of the plate body 1 is a low-position embedded groove, and the longitudinal groove block 2 is partially embedded in the plate body 1, and most (for example, 77%) of the longitudinal groove block 2 is exposed to the The top surface of the plate body 1.

[0047] The rail temporary fixing structure of the present invention can temporarily fix the rail components, facilitate the adjustment of the rails, and is suitable for the temporary fixing of the rails during the construction of the continuous support rail system; after the rail line is stabilized and finally fine-tuned, install the longitudinal groove block and Pouring polymer damping materials to accurately position and permanently fix the rail components, provide continuous support and continuous locking for the rails, basically eliminate the vibration source generated by the rails under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com