Degumming process of non-foaming beef tallow for hot pot

A butter and degumming technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of large loss of butter flavor, large loss of neutral oil, low yield of finished oil, etc., to achieve significant degumming effect and high yield , the effect of low flavor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

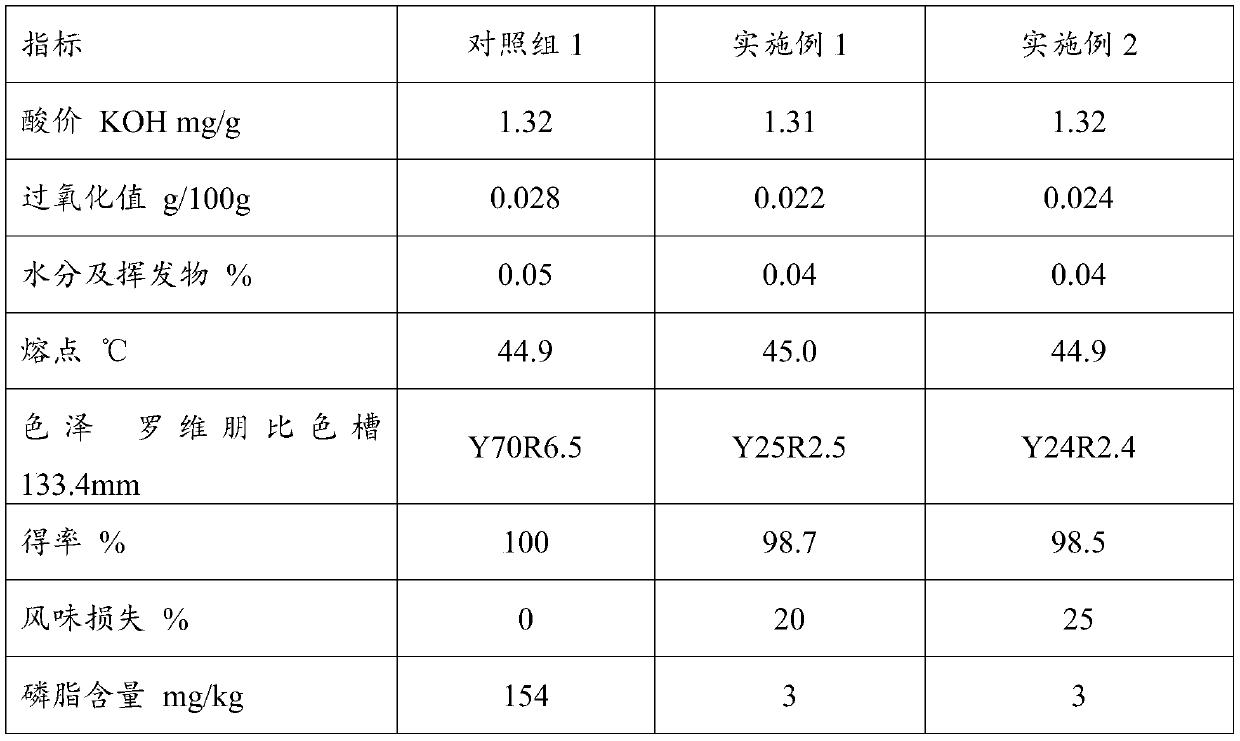

Embodiment 1

[0033] A degumming process for non-foaming hot pot butter, comprising the following steps:

[0034] S1 heat-treat tallow and keep it at 60°C to 100°C, and perform subsequent steps.

[0035] S2 adds degumming adsorbent to S1, and forms a mixed solution after fully stirring with tallow;

[0036] The degumming adsorbent includes silica, perlite and diatomaceous earth, wherein the degumming adsorbent accounts for 1.2% of the total weight of tallow, silicon dioxide accounts for 0.7% of the total weight of tallow, and perlite accounts for 0.3% of the total weight of tallow , diatomaceous earth accounts for 0.2% of the total weight of the butter; the stirring time is 30min to 60min, and the stirring speed is 20r / min to 30r / min.

[0037] S3 filters the mixed liquid in S2 to obtain non-foaming butter product; the filtering equipment is a leaf filter, the filter mesh of the leaf filter is 120 mesh, and the operating pressure is 0MPa-0.06MPa.

[0038] In this example, perlite and diato...

Embodiment 2

[0040] A degumming process for non-foaming hot pot butter, comprising the following steps:

[0041] S1 heat-treat tallow and keep it at 60°C to 100°C, and perform subsequent steps.

[0042] S2 adds degumming adsorbent to S1, and forms a mixed solution after fully stirring with tallow;

[0043] The degumming adsorbent includes silica, perlite and diatomaceous earth, wherein the degumming adsorbent accounts for 1.2% of the total weight of tallow, silicon dioxide accounts for 0.7% of the total weight of tallow, and perlite accounts for 0.3% of the total weight of tallow , diatomaceous earth accounts for 0.2% of the total weight of the butter; the stirring time is 30min to 60min, and the stirring speed is 20r / min to 30r / min.

[0044] S3 filters the mixed liquid in S2 to obtain non-foaming butter product; the filtering equipment is a leaf filter, the filter mesh of the leaf filter is 200 mesh, and the operating pressure is 0MPa-0.06MPa.

[0045] In this example, perlite and diato...

Embodiment 3

[0047] A degumming process for non-foaming hot pot butter, comprising the following steps:

[0048] S1 heat-treat tallow and keep it at 60°C to 100°C, and perform subsequent steps.

[0049] S2 adds degumming adsorbent to S1, and forms a mixed solution after fully stirring with tallow;

[0050] The degumming adsorbent includes silica, perlite and diatomaceous earth, wherein the degumming adsorbent accounts for 1.2% of the total weight of tallow, silicon dioxide accounts for 0.7% of the total weight of tallow, and perlite accounts for 0.3% of the total weight of tallow , diatomaceous earth accounts for 0.2% of the total weight of the butter; the stirring time is 30min to 60min, and the stirring speed is 20r / min to 30r / min.

[0051] S3 filters the mixed solution in S2 to obtain a non-foaming butter product;

[0052] The filter equipment is a plate and frame filter, the filter cloth of the plate and frame filter has a filter aperture of 1um, and the operating pressure is 0MPa ~ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com