Gas-slag separation device for drilling

A gas-slag separation and air-slag technology, which is used in safety devices, earth-moving drilling, gas discharge, etc., can solve the problems of blowhole and drilling slag not being effectively discharged, affecting the civilized production and quality standardization of underground tunnels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

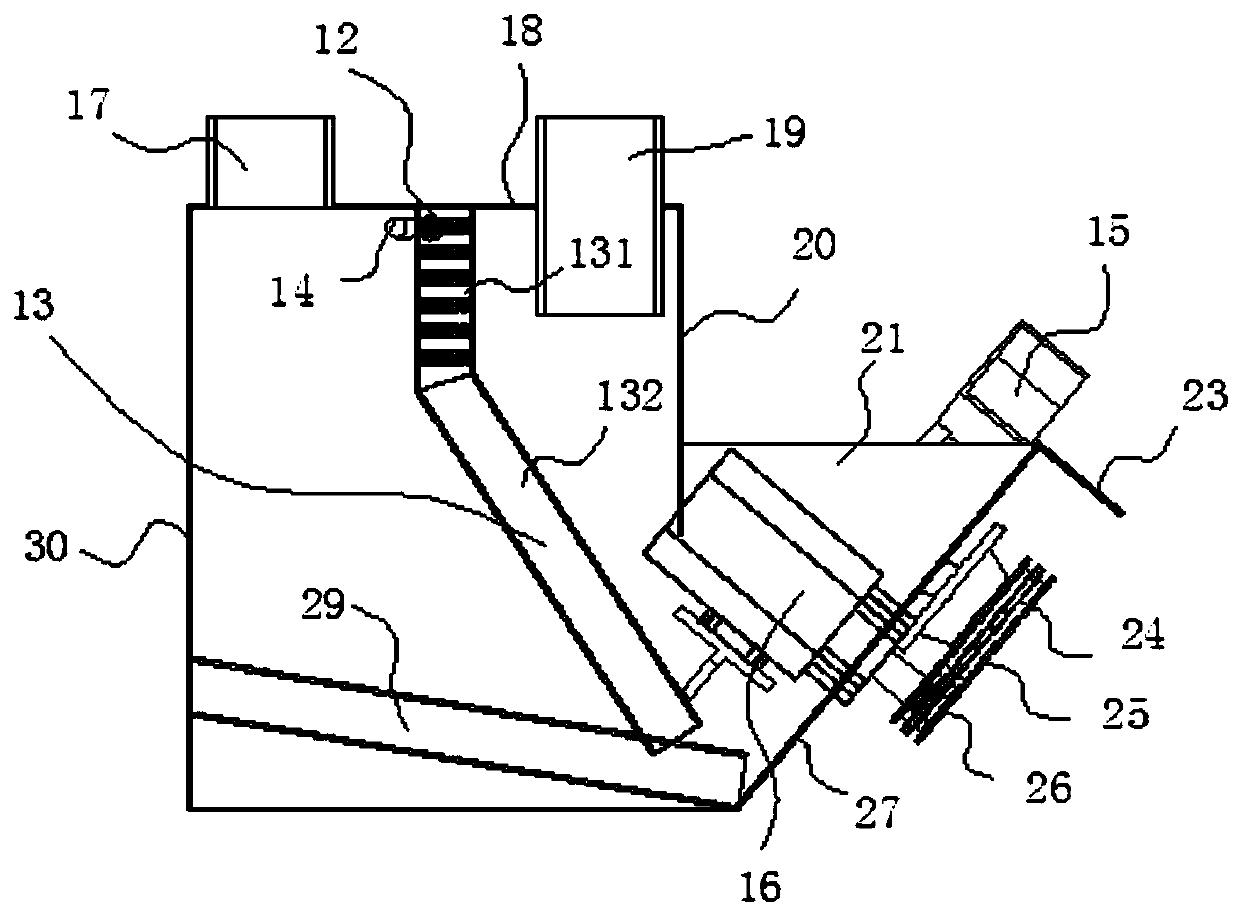

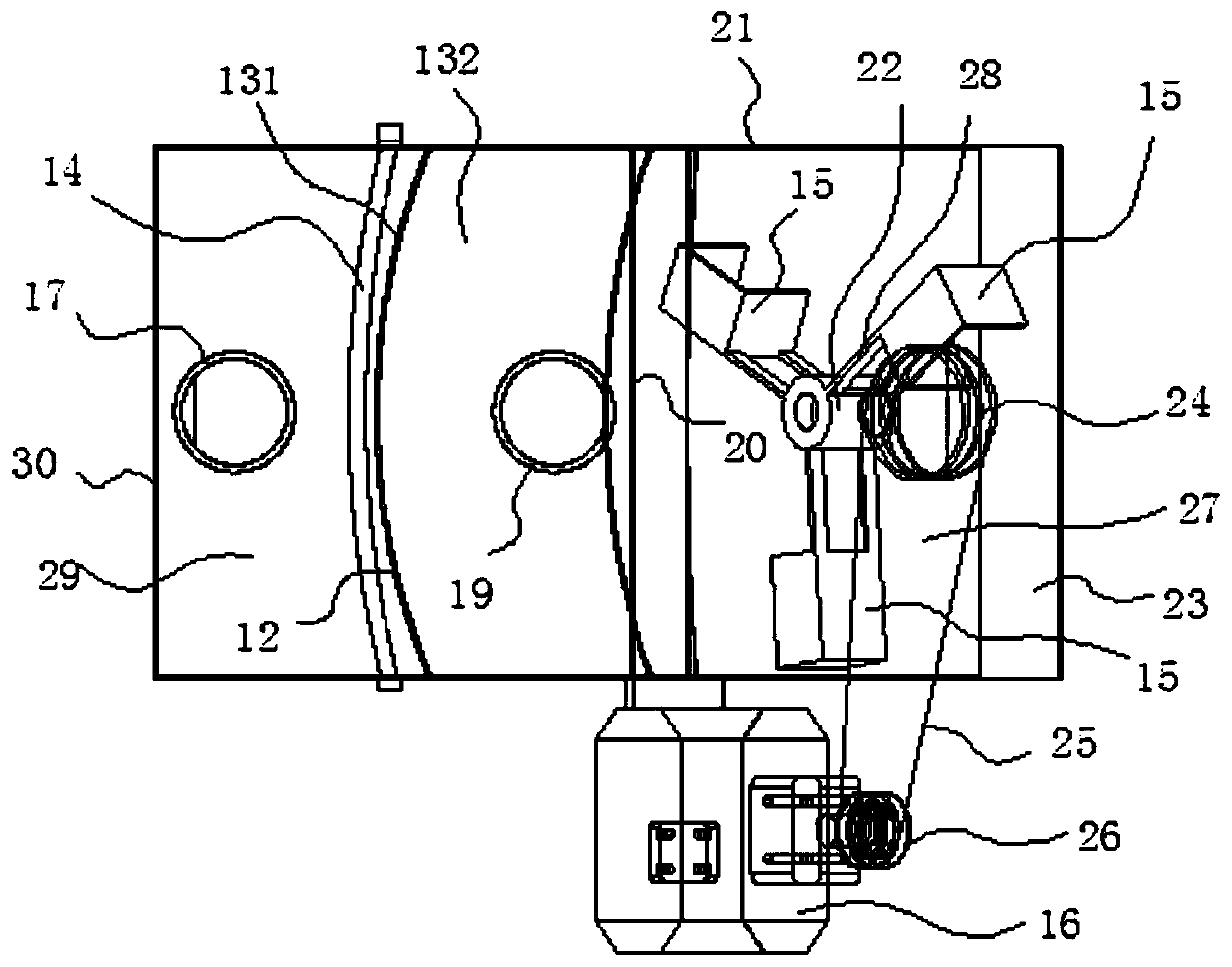

[0014] Embodiment 1: as attached Figure 1~2 As shown, a gas slag separation device for drilling, it includes two symmetrical wall panels 21, a left side panel 30, a partition 20 and a right side panel 27, the wall panel 21 is an L-shaped structure and Through the fixed connection of the left side plate 30 and the right side plate 27, the partition plate 20 is fixedly connected at the middle upper part of the wall plate 21, and the top of the wall plate 21, the left side plate 30 and the partition plate 20 is fixedly connected with a horizontal cover plate 18, The cover plate 18 is provided with an air slag inlet pipe 19 and a blowout prevention pipe 17, and the lower sloping plate 29 of arc-shaped structure is fixedly connected between the bottom of the left side plate 30, the bottom end of the right side plate 27 and the wall plate 21, and the right side plate 27 is arranged obliquely, and a slag lifting device is arranged on it, and the sliding plate 13 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com