Dried beef cutting equipment

A beef jerky and equipment technology, which is applied to meat processing equipment, meat cutting/trimming, processing meat, etc., can solve the problems of non-self-adaptation of beef, high equipment cost, easy to produce errors, etc., and achieves simple structure and production efficiency. High and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

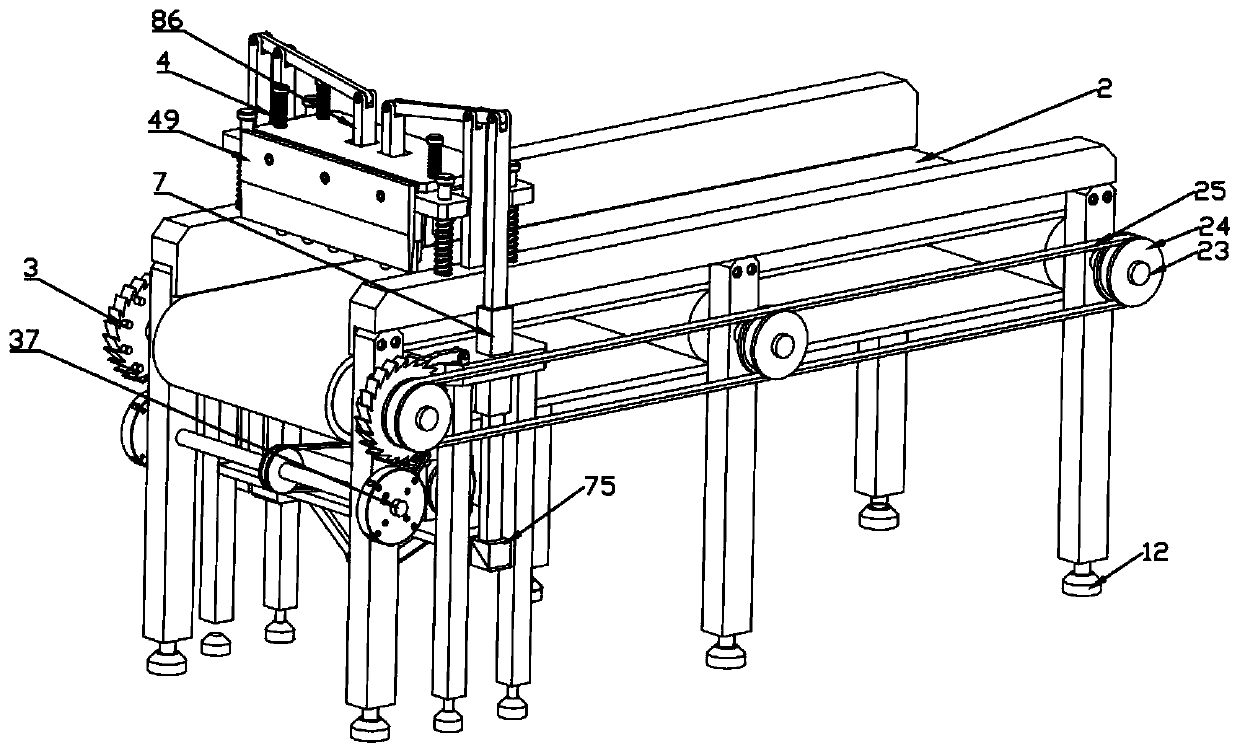

[0024] Such as Figure 1 to Figure 7 Shown, a kind of beef jerky slitting equipment comprises installation frame 1, intermittent rotation assembly 3 and conveying assembly 2, and the top of described conveying assembly 2 is provided with cutting assembly 4, and the conveyor belt 21 of conveying assembly 2 is provided with and The supporting plate 6 corresponding to the cutting assembly 4 is provided with a motor 8 and a connecting rod assembly 7 below the conveying assembly 2, and the motor 8 drives the connecting rod 37 in the intermittent rotating assembly 3 to rotate, and drives the connecting rod assembly 7 to rotate at the same time. The vertical moving rod 2 80 of the connecting rod assembly 7 moves up and down, the hinge rod 72 in the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com