Waterproof composite cable

A composite cable and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of difficulty in finding cables, corrosion of the inner protective layer of the cable core, and shortening of the service life of cables, so as to prevent damage and reduce economic losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

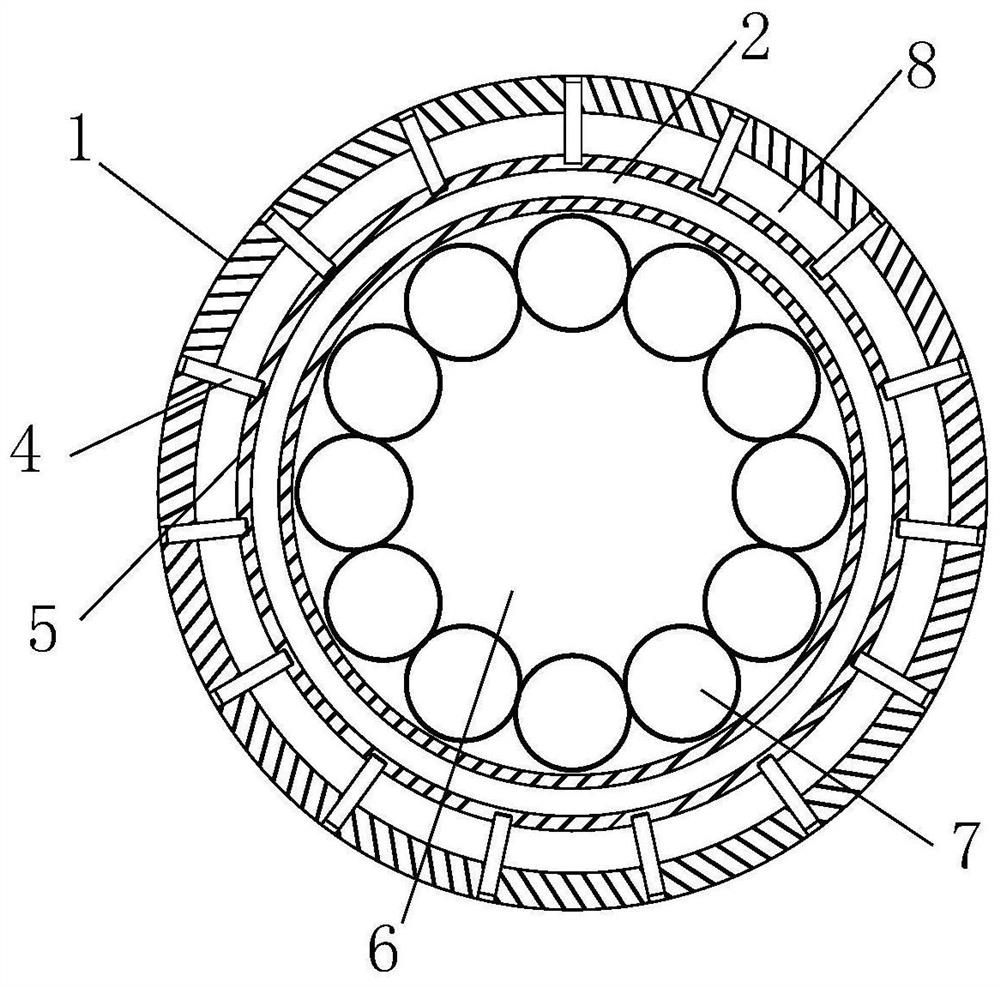

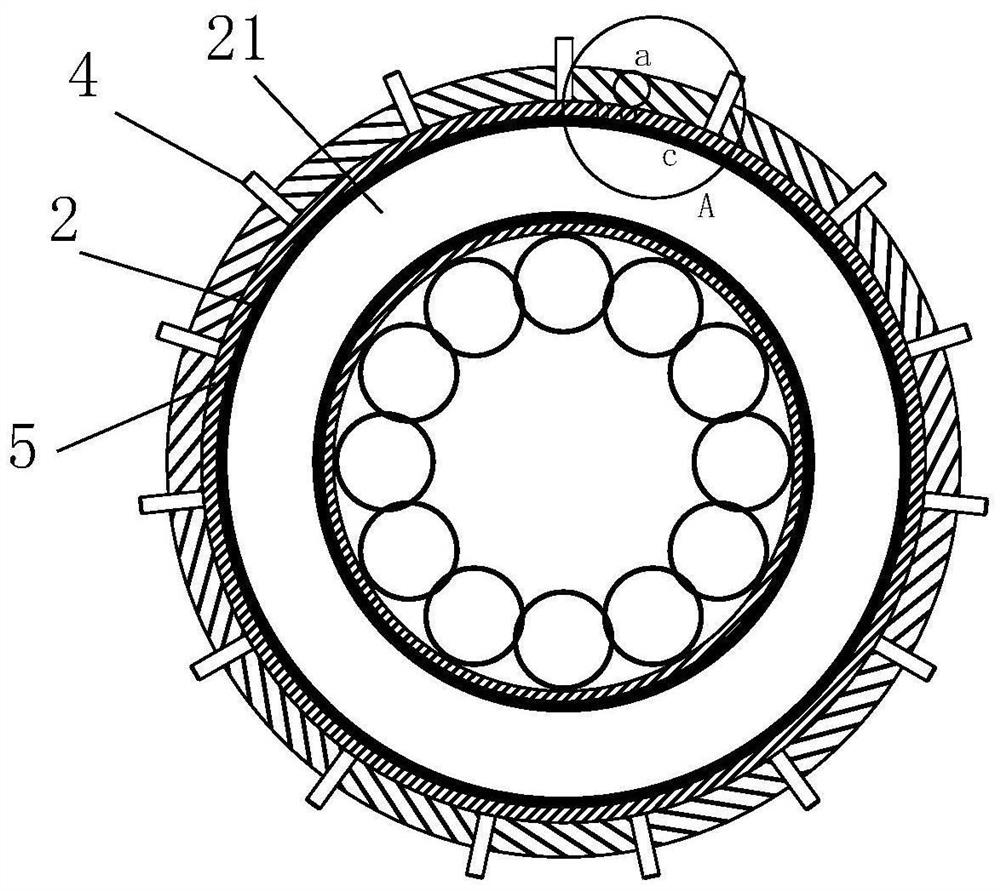

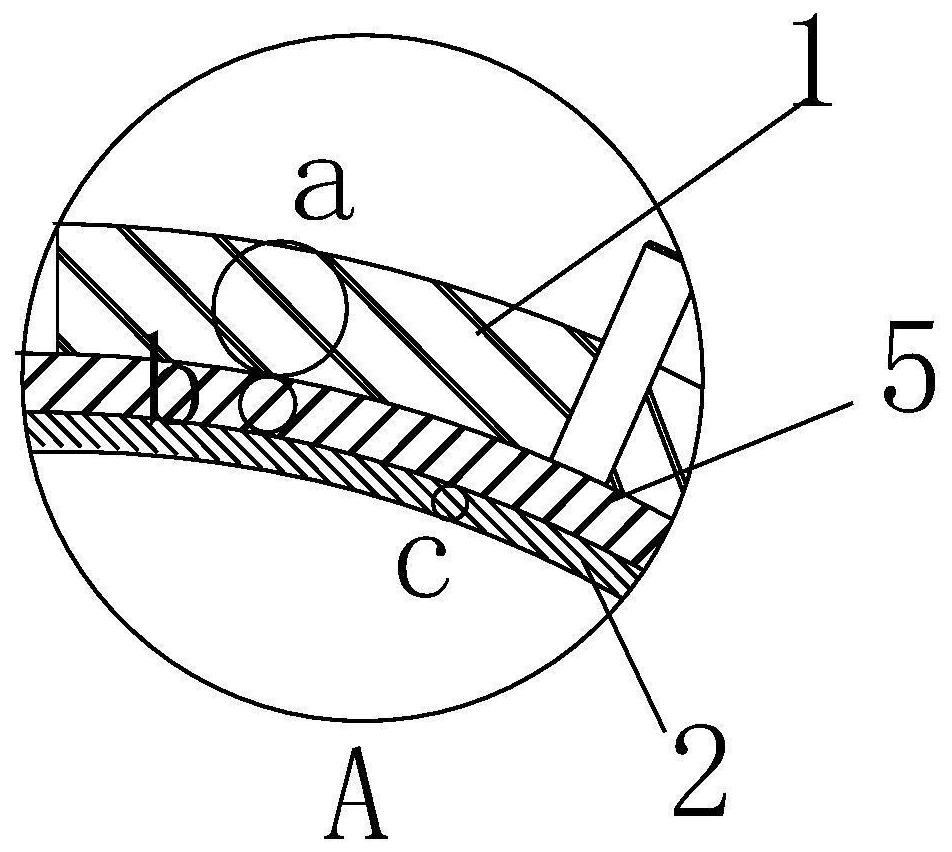

[0020] Such as figure 1 As shown, the waterproof composite cable includes a cable outer layer 1, an expansion protective layer is arranged inside the cable outer layer 1, and more than one connecting rod 4 is inserted into the outer surface of the expansion protective layer, and one end of the connecting rod 4 Insert and fix in the outer wall surface of the expansion protection layer, and the other end is sealed and inserted into the through hole opened on the cable outer layer. When the expansion protection layer inhales and expands, each connecting rod 4 protrudes from the outside of the cable outer layer;

[0021] There is a cable installation cavity 6 in the middle of the expansion protection layer, and more than one strand of cable core wires 7 are all arranged in the cable installation cavity 6 .

[0022] In this embodiment, the expansion protection layer protects the first expansion layer 5 and the second expansion layer 2. There is a first suction cavity (not shown) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com