Method and device of automatically monitoring suspended load sediment by replacement method

A technology for automatic monitoring and mass removal. It is used in measurement devices, surveying and navigation, and open-air water source surveys. It can solve the problems of direct use restrictions of hydrological stations, no product promotion and use, and manual working conditions. It is easy to realize and popularize. , Significant practical value, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

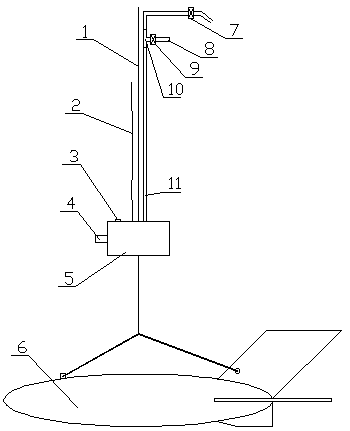

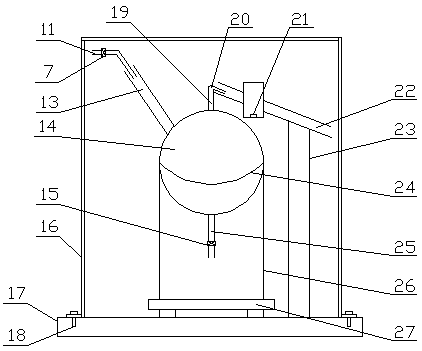

[0042] Example: see figure 1 and figure 2, in the figure, 1-cable, 2-signal line, 3-temperature sensor, 4-submersible pump inlet, 5-submersible pump, 6-lead fish, 7-upper water pipe solenoid valve, 8-drainage pipe, 9-drainage Pipe solenoid valve, 10-tee, 11-submersible pump water pipe, 13-container water inlet, 14-water container, 15-drain pipe solenoid valve, 16-protection cylinder, 17-base, 18-fixing bolt, 19 -overflow pipe, 20-duckbill pipe, 21-temperature sensor, 22-overflow drain pipe, 23-overflow drain pipe leg, 24-round bracket, 25-drainage pipe, 26-leg, 27- load cells.

[0043] The device for automatic monitoring of suspended sediment by displacement method includes an underwater part and an above-water part.

[0044] 1. Underwater part:

[0045] Install the miniature submersible pump 5 above the lead fish 6 of the hydrological flow measurement cableway or flow measurement winch or other fixed hydrological flow measurement facilities, the water inlet 4 of the mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com