Cold and heat difference-prevention reflection-type material level calibration instrument of light beam

A reflective technology for calibrating instruments, applied to instruments, liquid level indicators, machines/engines, etc., can solve problems such as beam amplification offset, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 to attach Figure 7 Shown:

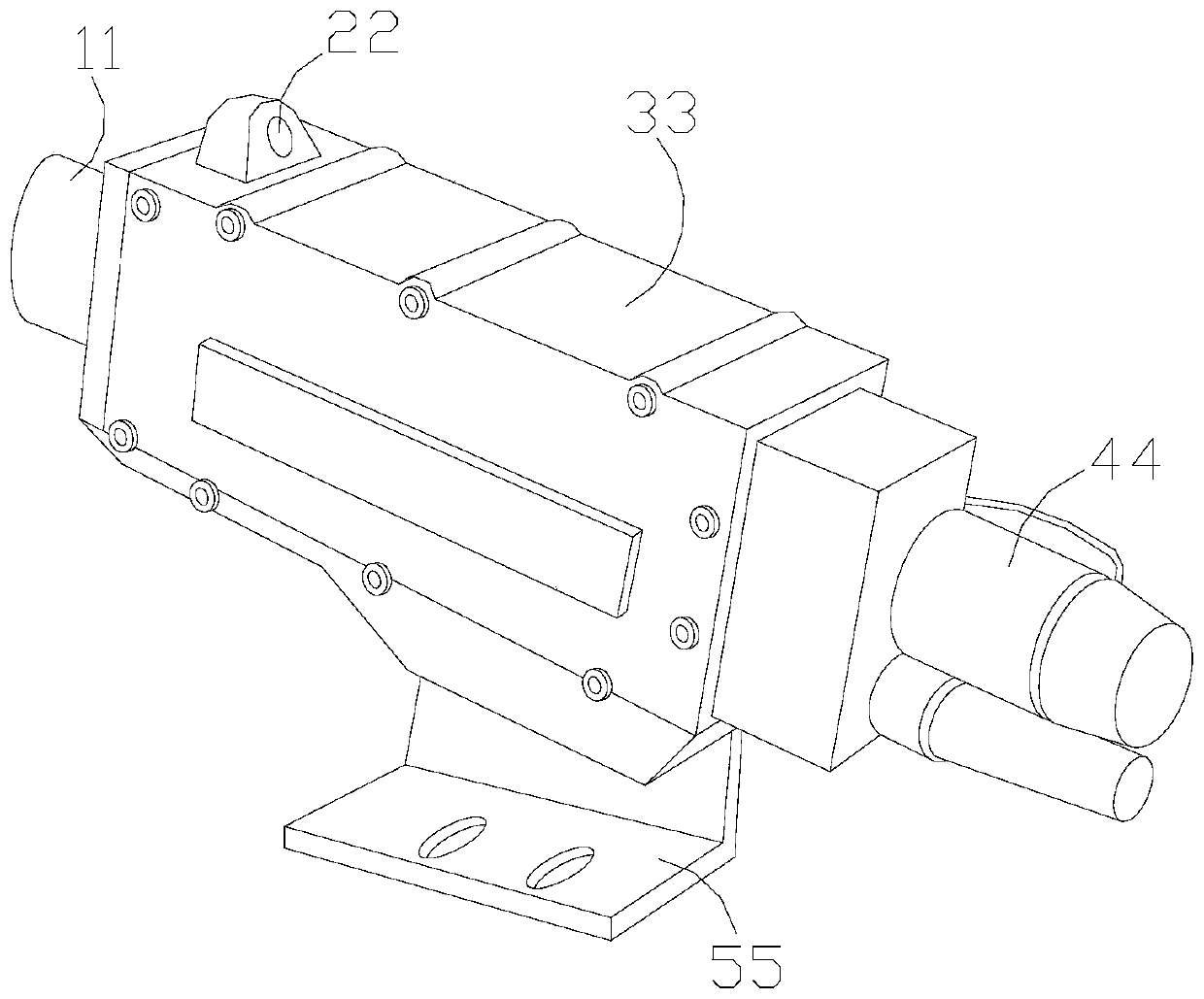

[0029] The present invention provides a light beam anti-cold and heat difference reflection type level calibration instrument, the structure of which includes a concentrating irradiation head 11, a tracing hole 22, a level calibration instrument 33, an adjusting rotary head 44, and a bottom fixing seat 55.

[0030] The condensing irradiation head 11 runs through the interior of the level calibration instrument 33, the trace hole 22 is welded to the outer surface of the level calibration instrument 33, and the end of the level calibration instrument 33 away from the condensing irradiation head 11 is connected with the adjusting rotary head. 44, and the bottom fixing seat 55 is installed on the bottom surface of the level calibration instrument 33.

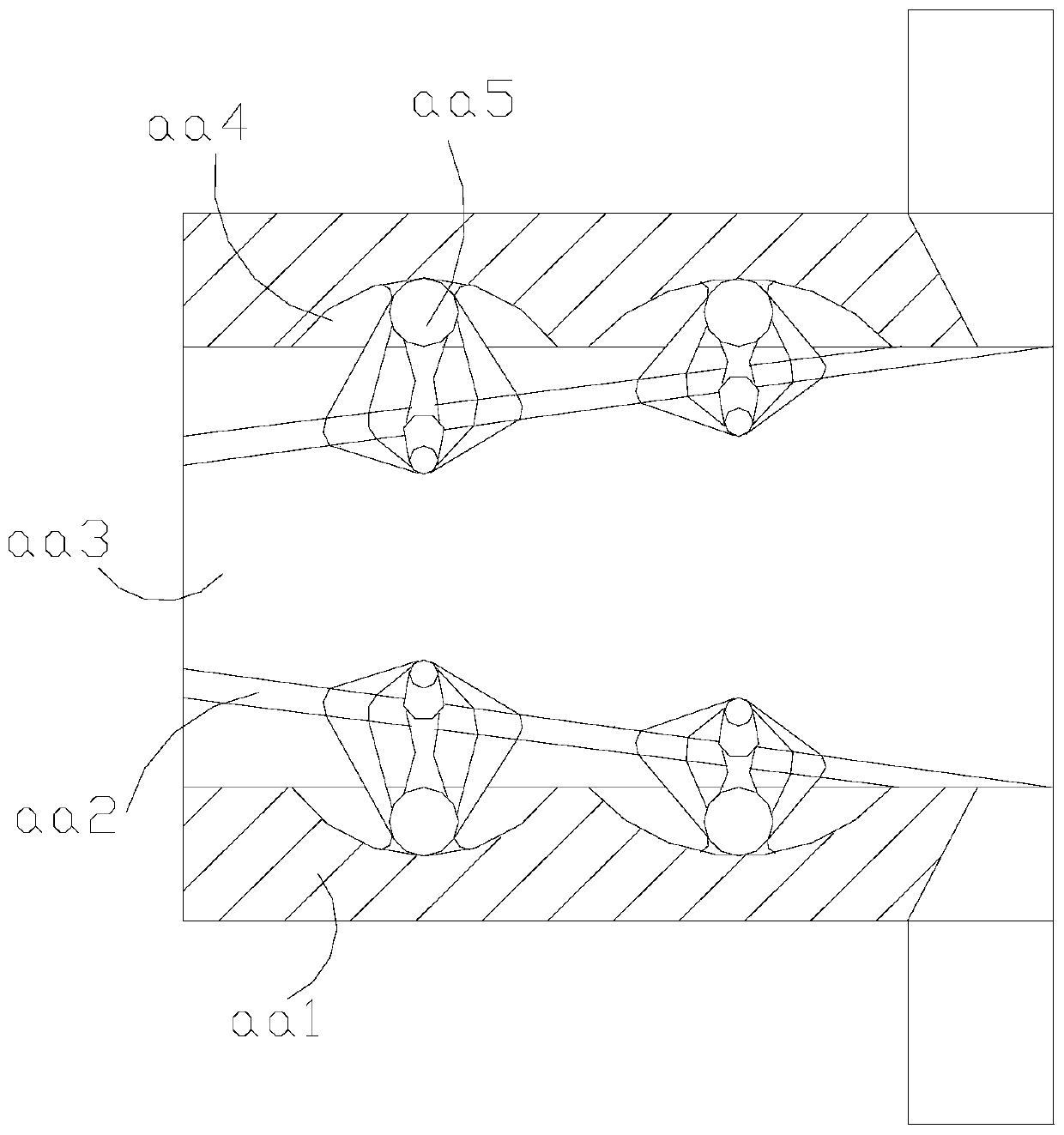

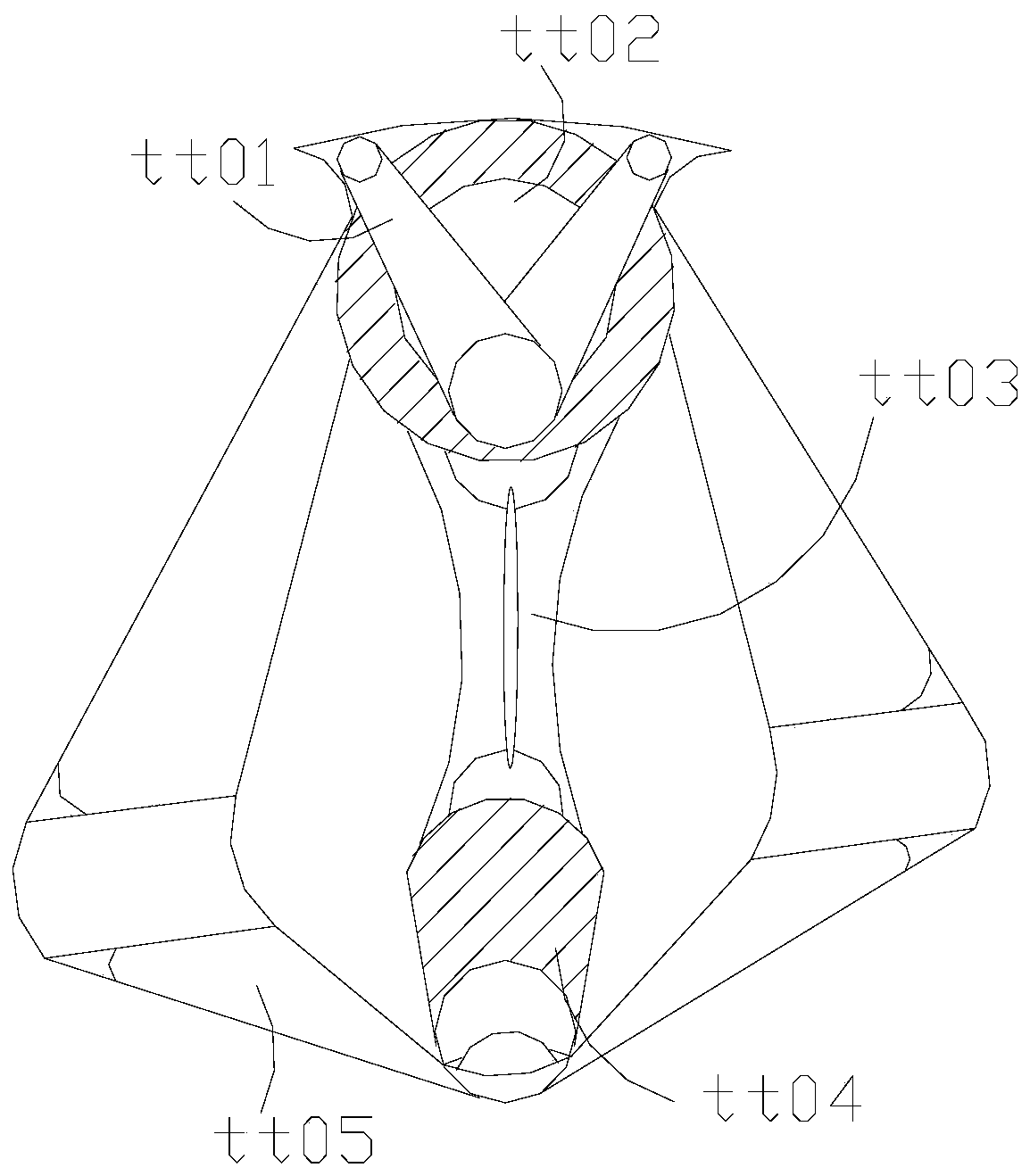

[0031] The condensing irradiation head 11 includes an outer limiting shell aa1, a condensing edge aa2, a hollow opening aa3, a solid arc head aa4, and a water bead support a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com