Method for continuously monitoring side wall deformation in tunnel invert excavation process

A technology for side walls and tunnels, applied in measuring devices, surveying and navigation, height/horizontal measurement, etc., can solve problems such as lack of continuous and reliable monitoring of side walls, and achieve accurate guidance for on-site construction, simple and easy installation, and accurate forecasting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

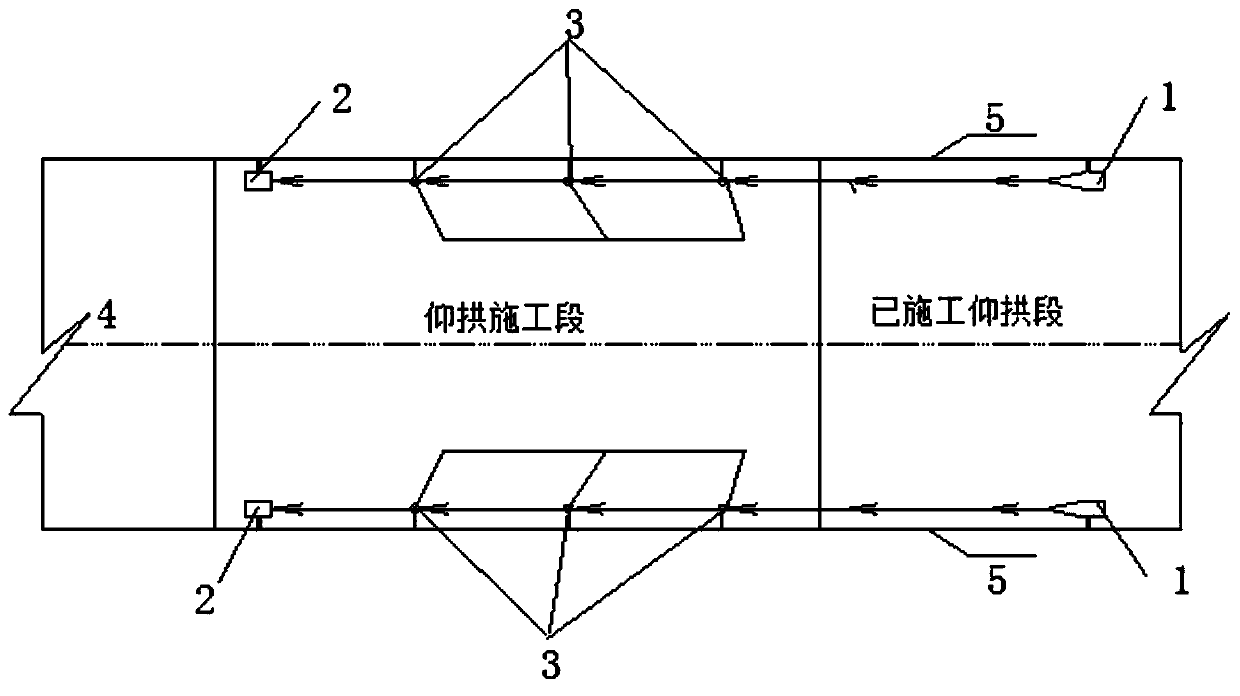

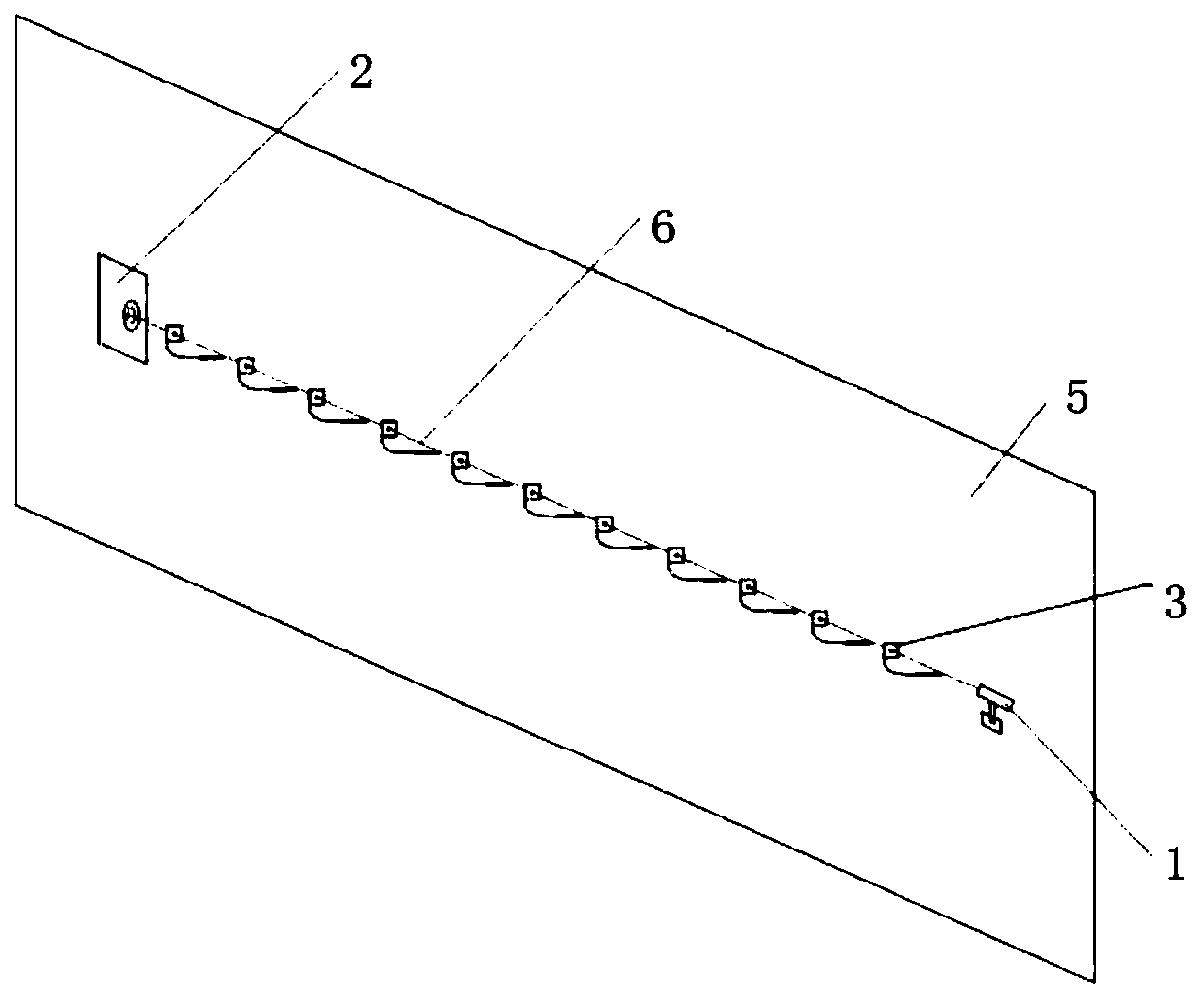

[0037] 1. Install the infrared generator 1 and the infrared receiver 2 respectively on the two side walls of the inverted arch section that has been constructed, and on the two side walls of the inverted arch excavation section near the end of the tunnel face 4; the height distance The top of the short side wall is about 1.3m (it is advisable not to damage the waterproof board). When installing, ensure that the infrared generator 1 and the infrared receiver 2 are firm and not loose. The distance between the infrared generator 1 and the infrared receiver 2 is 8m.

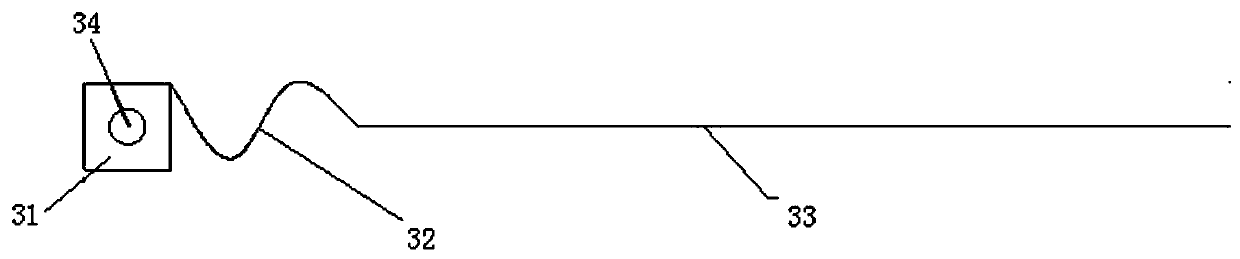

[0038] 2. The production of infrared rays through the ring 3: before the excavation of the inverted arch, use The steel bar 33 is processed with infrared rays passing through the ring 3, one end of the steel bar 33 is welded with 8# steel wire 32, the other end of the steel wire 32 is welded with a 4×4cm steel plate 31, the thickness of the steel plate 31 is not less than 2mm, and an infrared ray with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com