Automatic wall building system

A technology for building walls and beams, applied in the field of automatic wall-building systems, which can solve the problems of labor-intensive, complex overall structure, and cumbersome overall control procedures, etc., to achieve improved wall-building effects, simple overall structure, and three-axis movement control process Convenience and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

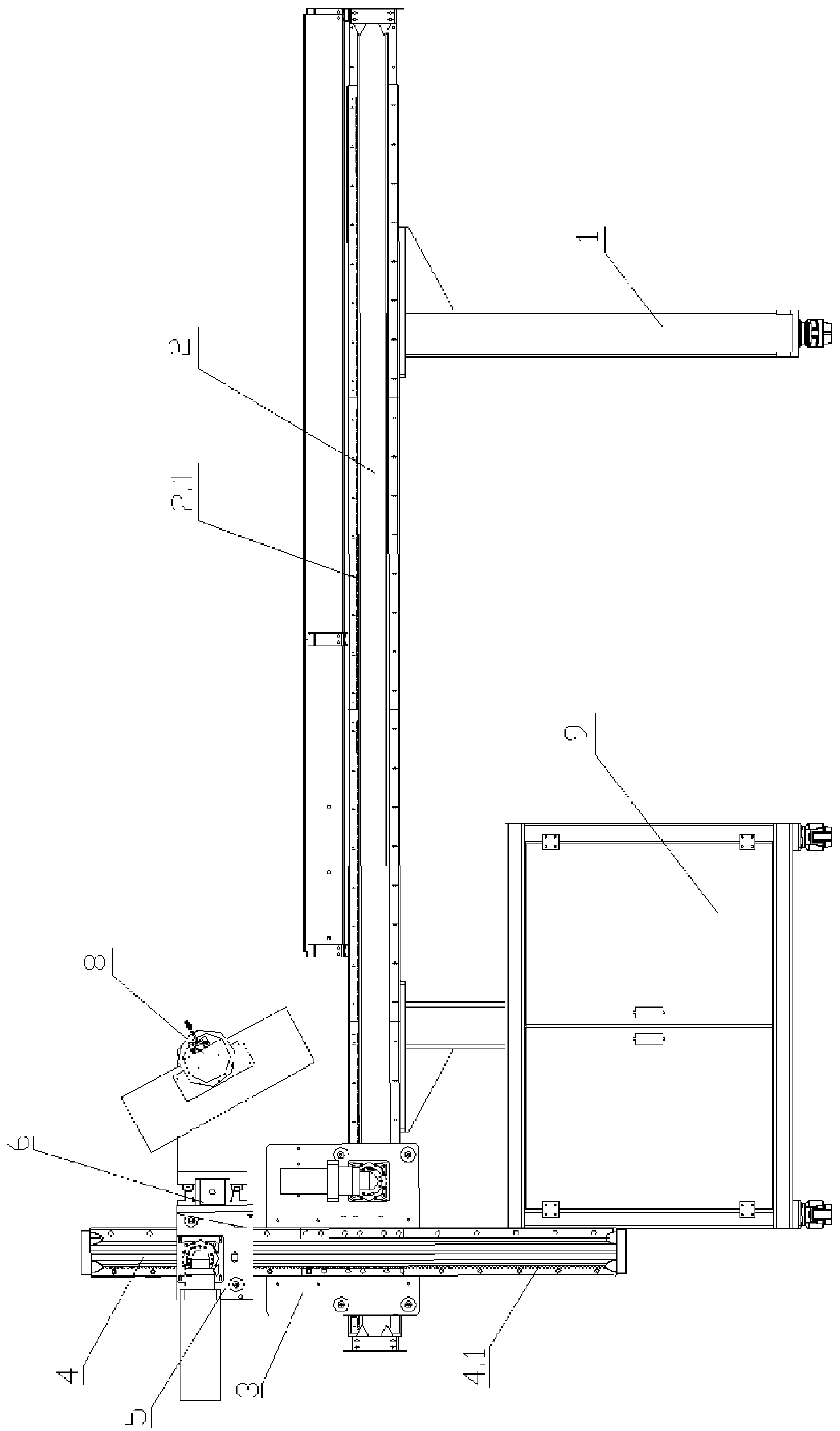

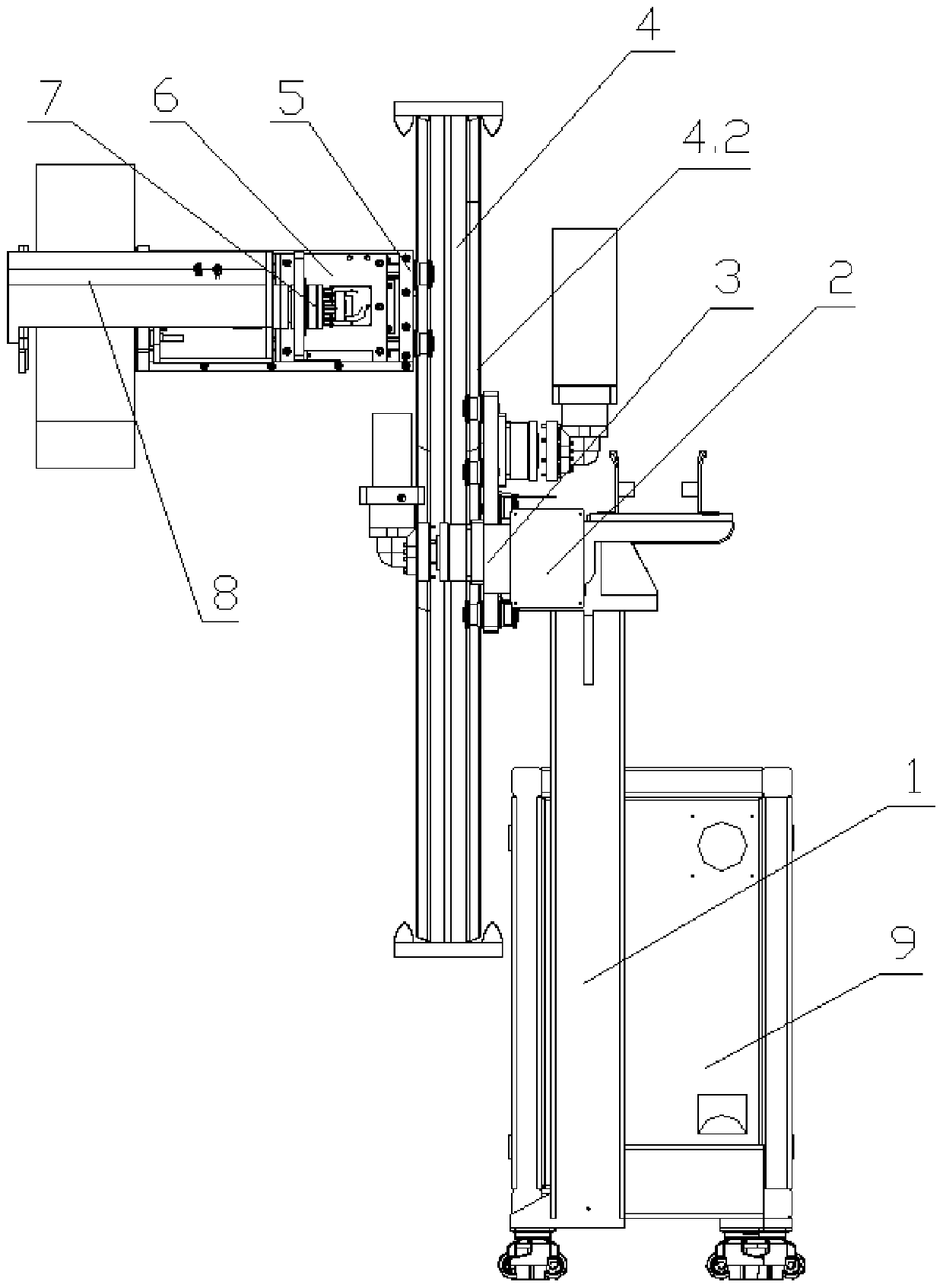

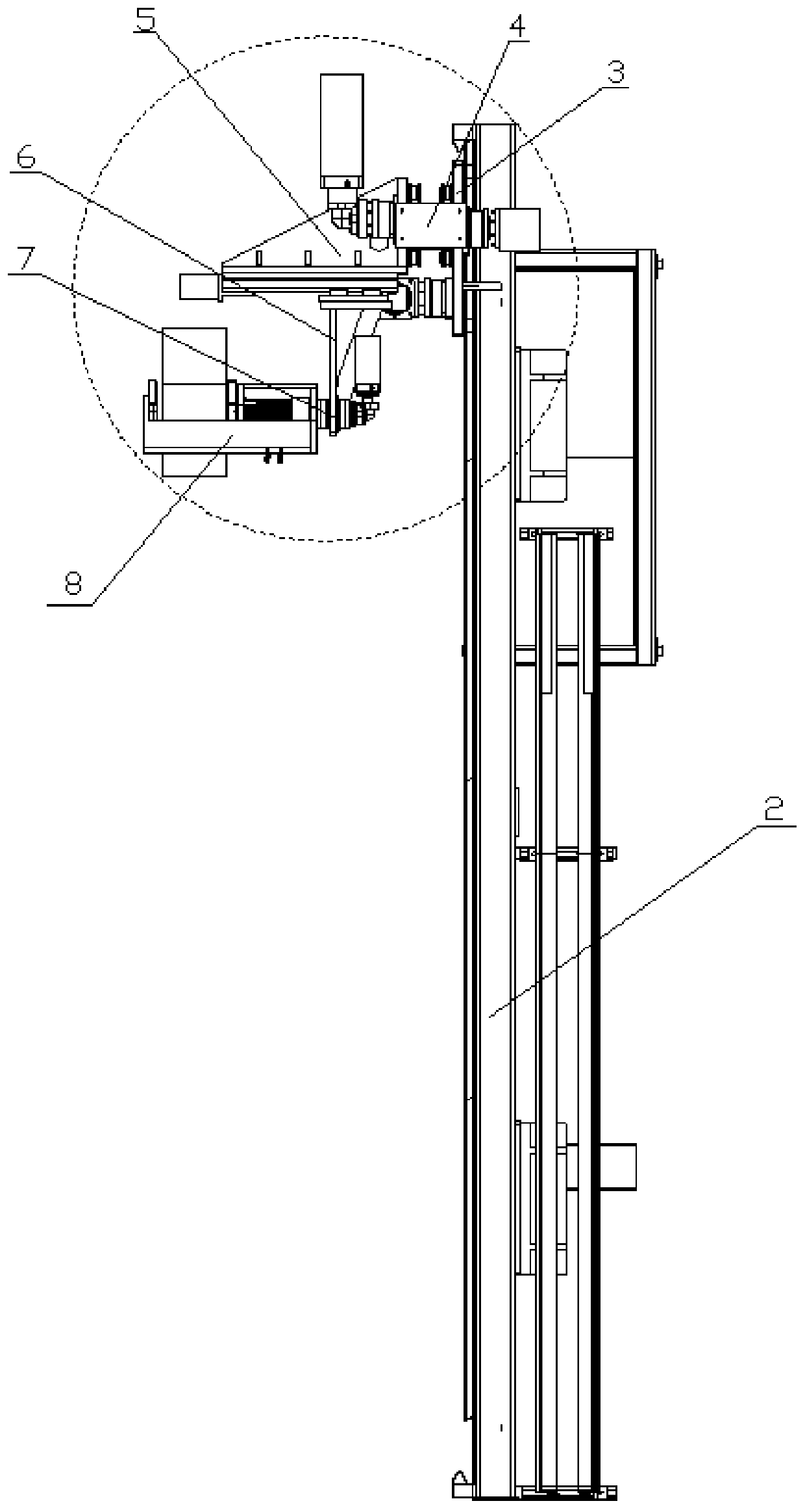

[0036] See Figure 1~4 , The present invention relates to an automated wall masonry system, the system includes a beam 2 horizontally erected on the ground through a column 1, the beam 2 is provided with a transversal frame 3 that moves along its length. A longitudinal beam 4 is vertically arranged on the moving frame 3, and the lifting frame 5 is slidably arranged on the longitudinal beam 4; the lifting frame 5 is provided with a translation frame 6 for horizontal movement, and the moving direction of the translation frame 6 is the same as the length of the cross beam 2. The direction is perpendicular; the translation frame 6 drives a clamping mechanism 8 through the rotating mechanism 7;

[0037] The clamping mechanism 8 includes a clamping support frame 8.1, the rotation mechanism 7 drives the clamping support frame 8.1 to rotate, one end of the clamping support frame 8.1 is fixedly installed with a clamping plate 8.3, and the other end is installed with a clamping Driving mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com