Trash-cleaning machine with trash-cleaning guide groove

A technology of cleaning machine and cleaning guide, which is used in the cleaning of open water surfaces, earthmoving machines/shovels, water conservancy projects, etc. Clean up the underwater suspended dirt of the trash rack and other problems, so as to reduce the bottom pressure and improve the grabbing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

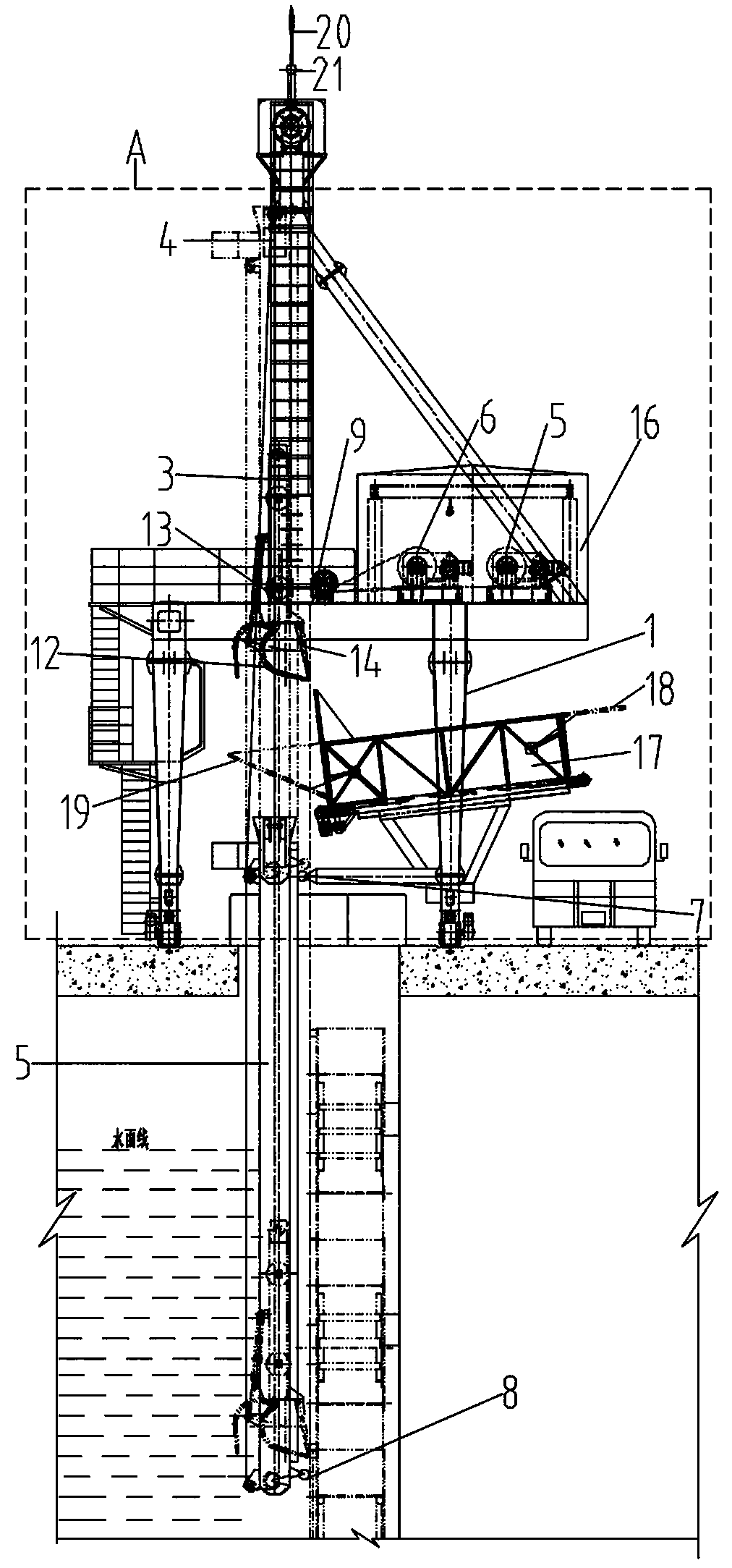

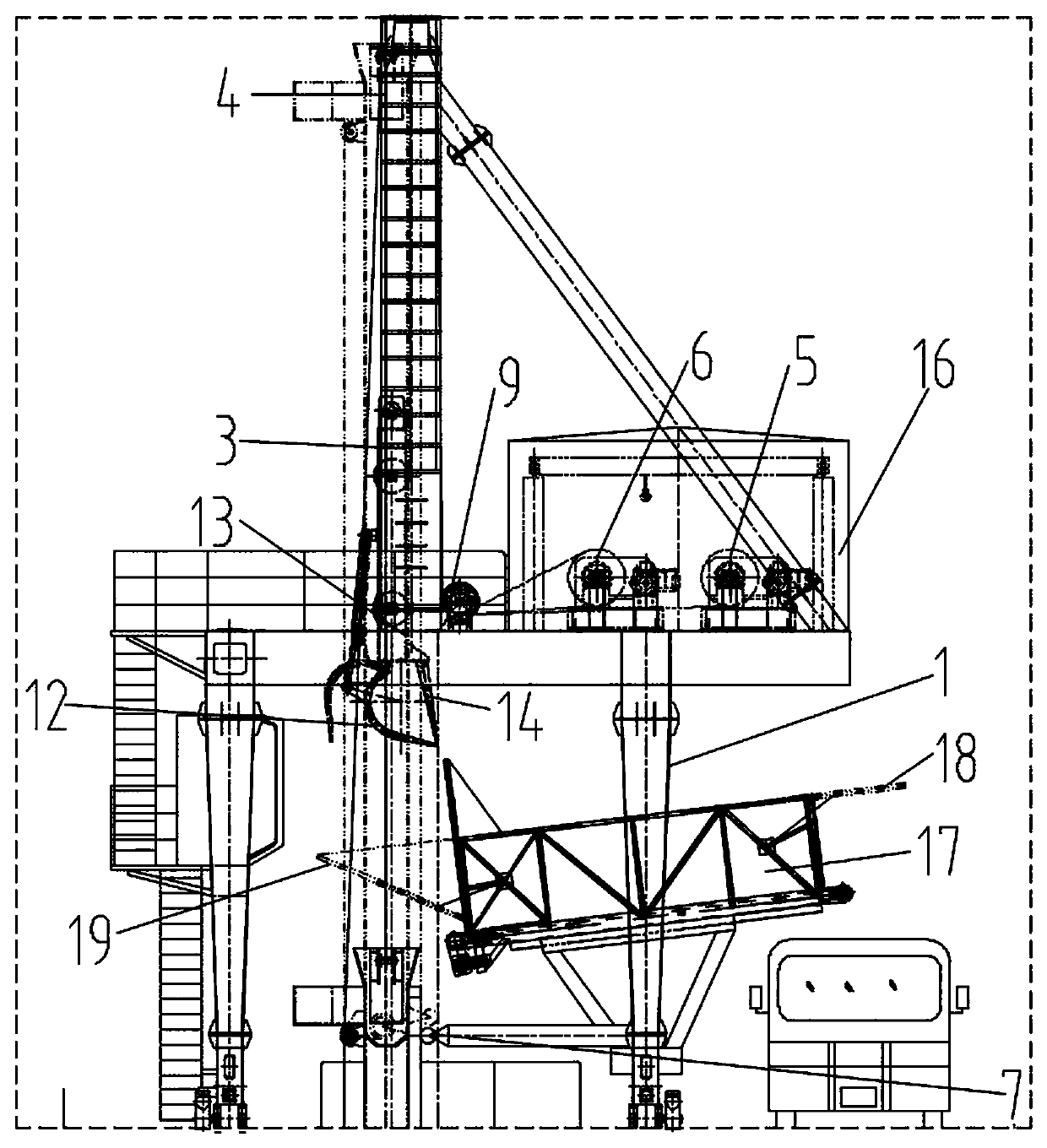

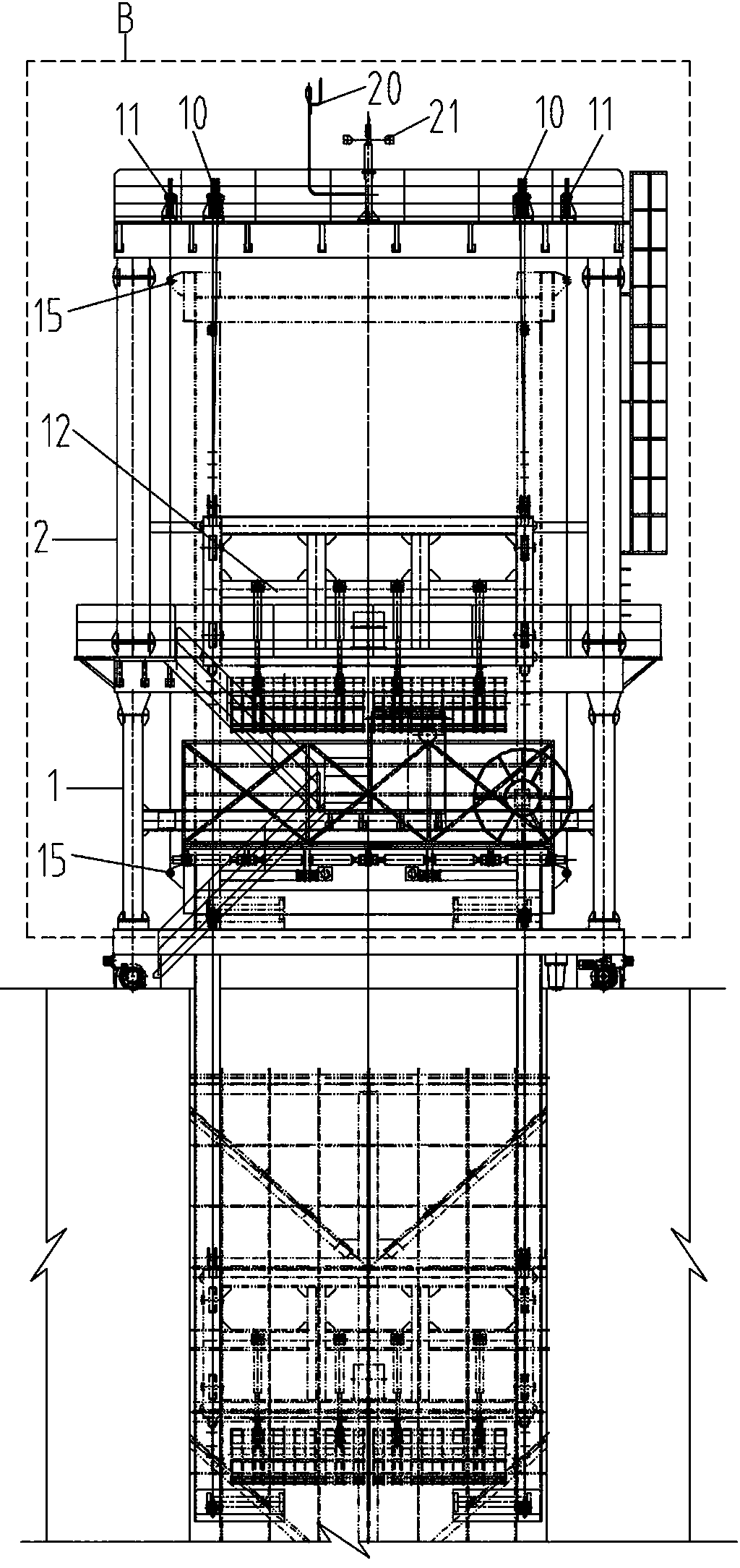

[0030] The invention provides a cleaning machine with a cleaning guide trough, which includes a walking door frame, a dirt grabbing mechanism 3, a cleaning guide trough 4, a guide trough lifting mechanism 5 and a grab bucket lifting mechanism 6. Groove lifting mechanism 5 and grab bucket lifting mechanism 6 are all fixed on the walking gantry, and described cleaning guide groove 4 is a U-shaped channel steel in cross section, and described cleaning guide groove 4 is fixed with guide groove lifting mechanism 5 connected; the dirt grabbing mechanism 3 is fixedly connected with the grab lifting mechanism 6, and the dirt grabbing mechanism 3 is located in the cleaning channel 4; the bottom of the cleaning channel 4 is provided with a lower support wheel 8, The upper support wheel 7 for supporting the decontamination guide groove 4 is fixedly arranged on the walking type gantry, and the decontamination guide groove 4 passes through the upper support wheel 7 and the lower support whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com