Lime production system

A production system, lime technology, applied in the field of lime production system, can solve problems such as cracking and waste, achieve the effects of reducing the amount of coal powder, improving quality, and facilitating detection and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

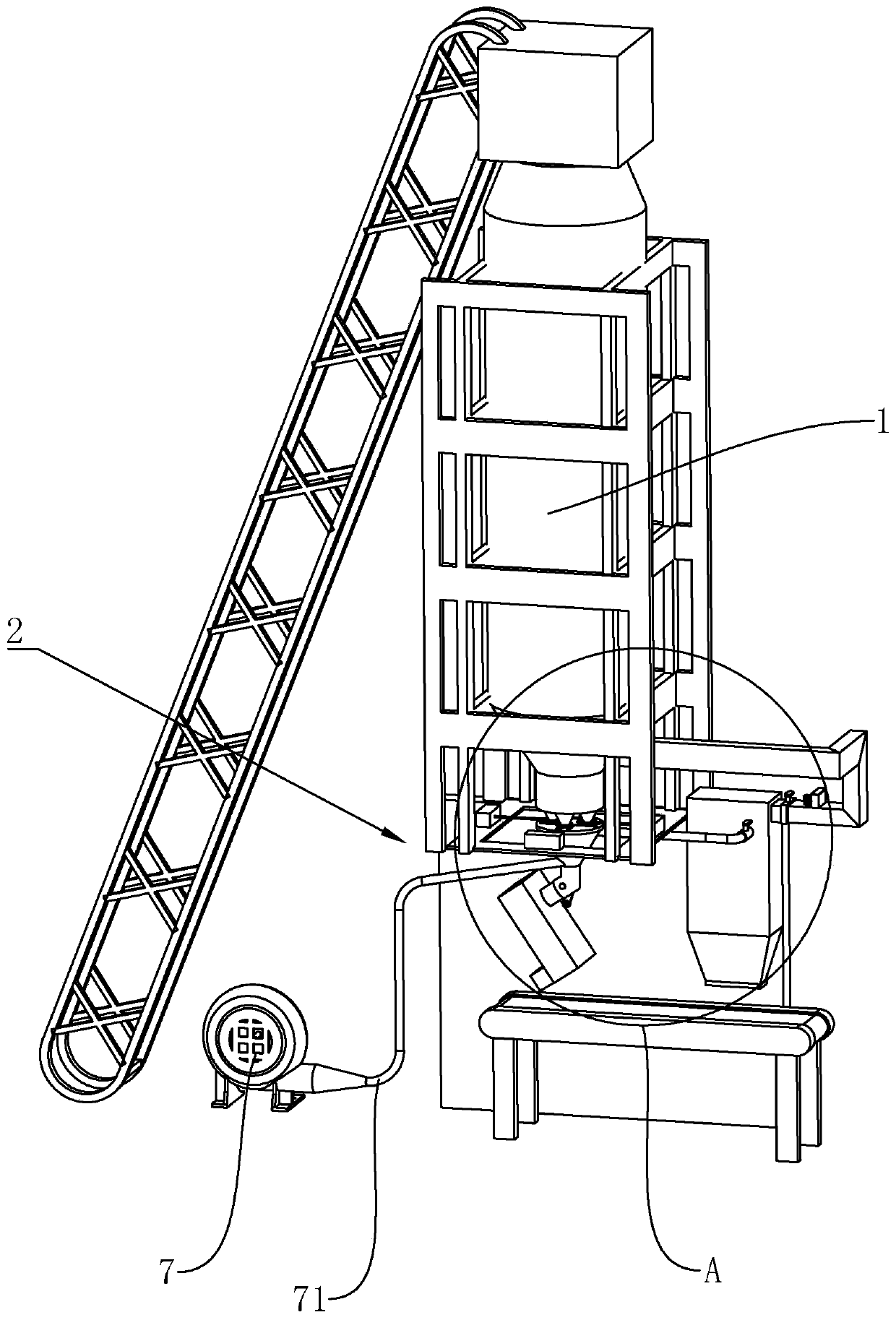

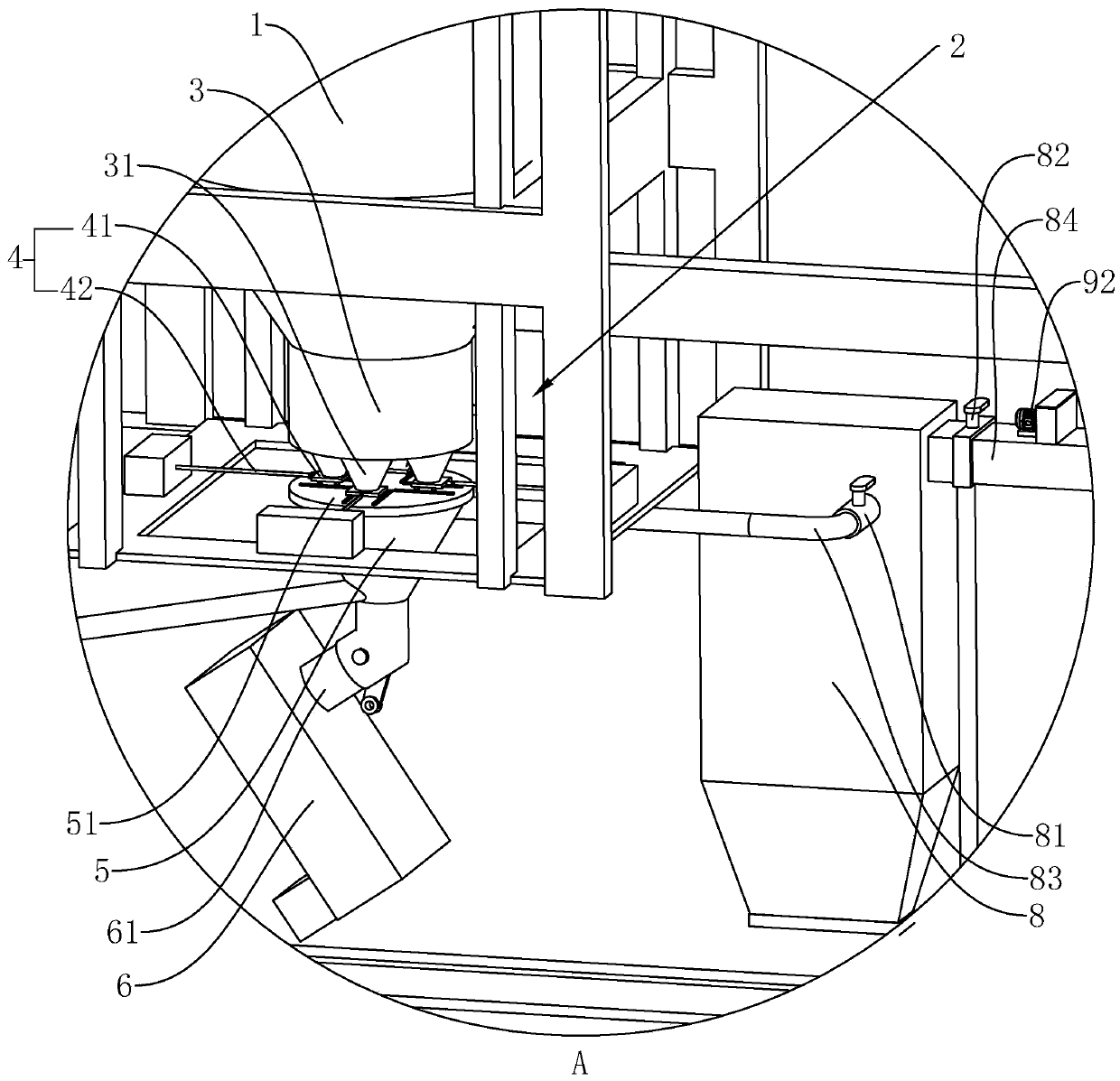

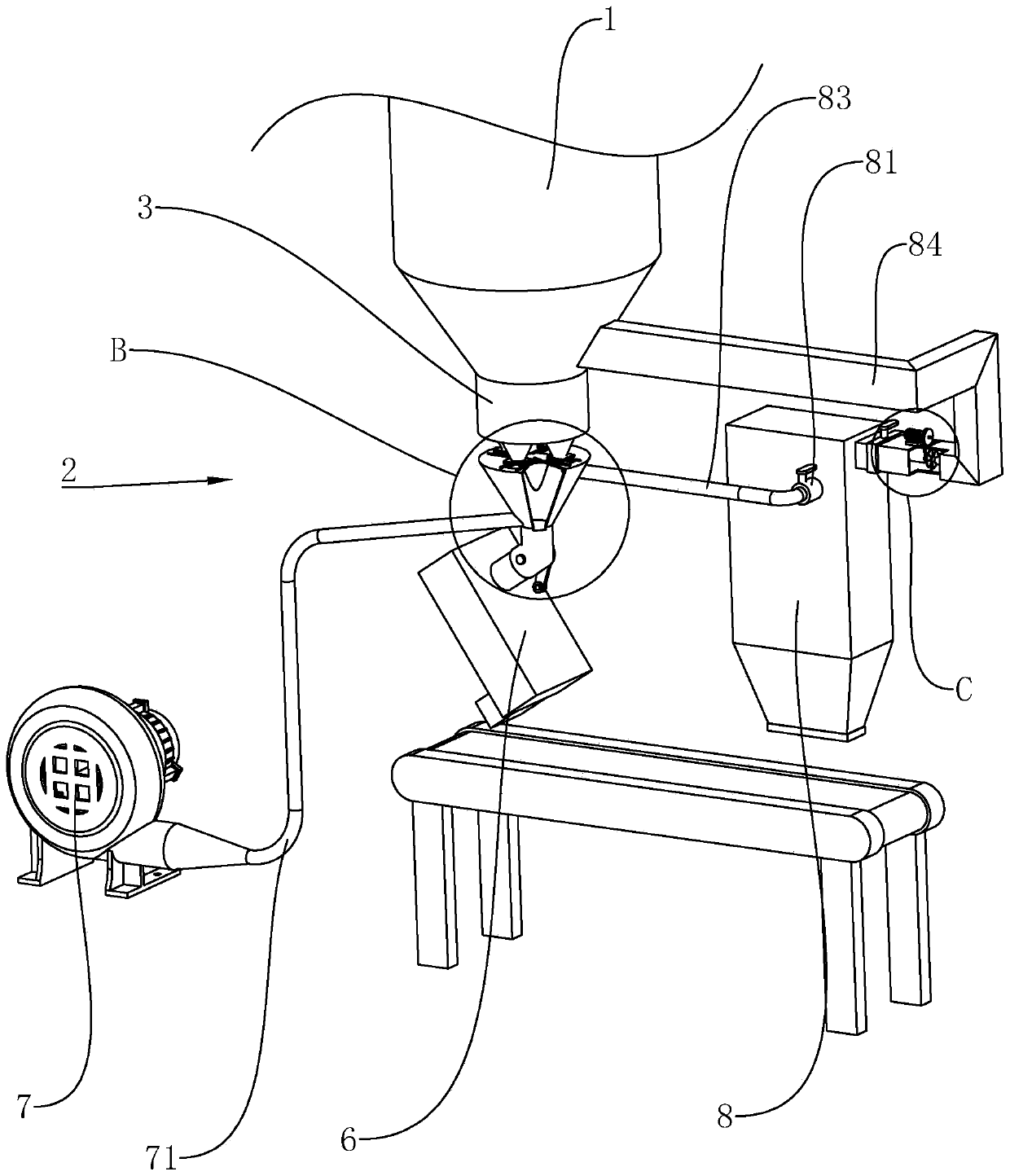

[0032] refer to figure 1 and figure 2 , is a lime production system disclosed in the present invention, which includes a kiln body 1 and an ash unloading device 2 installed on the lower end of the kiln body 1 . The ash unloading device 2 consists of a receiving hopper 3 , an ash discharger 4 , a first ash unloading hopper 5 and a second ash unloading hopper 6 connected in sequence from top to bottom.

[0033] refer to figure 2 and image 3, the upper end of the receiving bucket 3 is fixedly connected with the bottom end of the kiln body 1, and four lower feeding cylinders 31 are welded on the bottom surface of the receiving bucket 3. The cross-section of one end connected is larger than the end away from the bottom surface of the receiving bucket 3 . In the projection of each lower barrel 31 on the horizontal plane, the centers of each projection are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com