A kind of preparation method of metal porcelain tooth

A metal-ceramic and porcelain-fused-to-metal technology, which is applied to dentures and other fields, can solve problems such as waste of manpower and materials, and a large number of air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

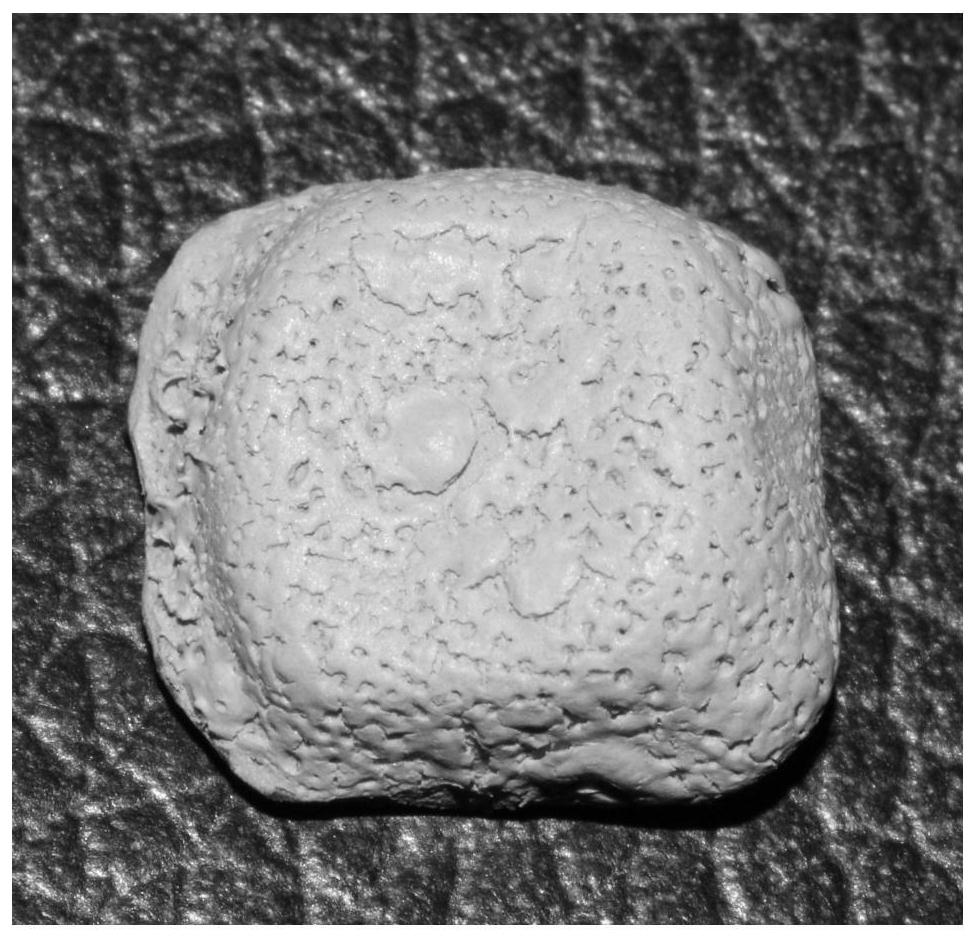

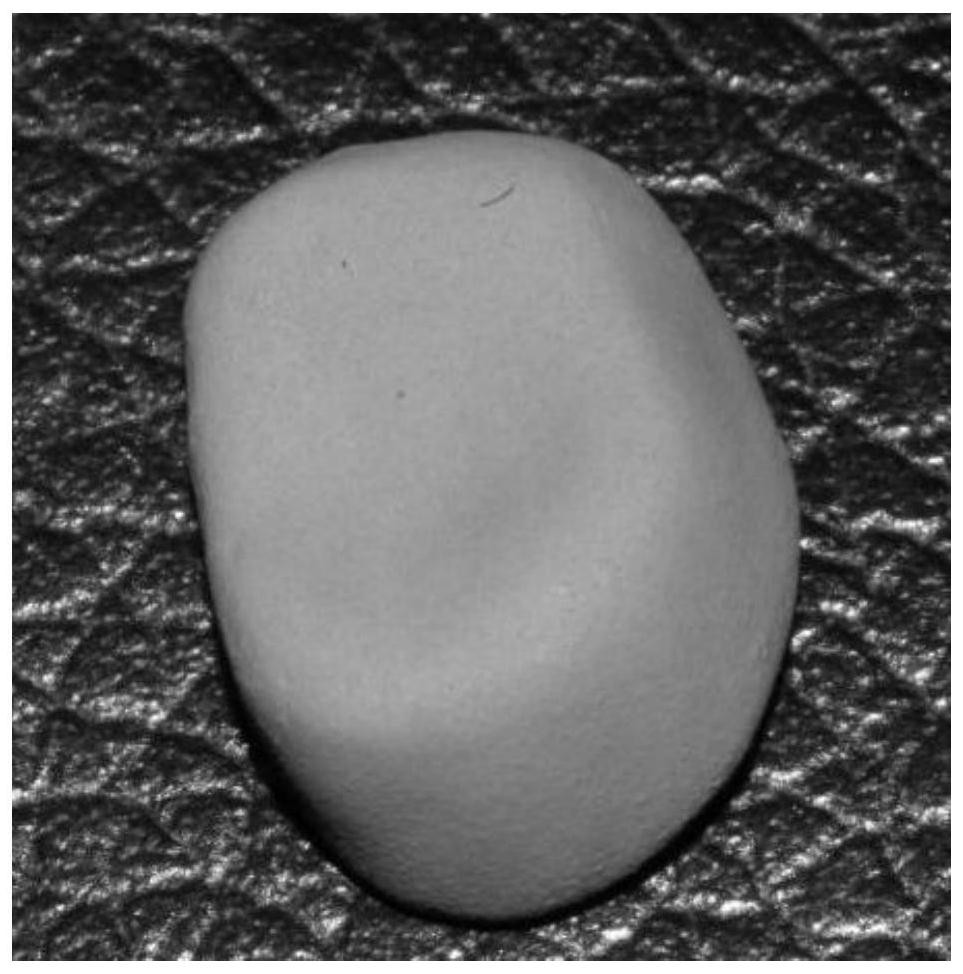

Image

Examples

Embodiment 1

[0023] A method for preparing metal-ceramic teeth, comprising the following steps:

[0024] Step 1: Prepare metal-ceramic inner crown;

[0025] Step 2: After plastic-shading porcelain is deposited on the surface of the inner crown, it is dried at 500°C for 8 minutes and then placed in a porcelain furnace. The furnace is heated from 500°C to 900°C at a heating rate of 60°C / min under vacuum. Vacuum sintering for 15 minutes to obtain metal-ceramic teeth treated at one time;

[0026] Step 3: After one-time treatment of metal-ceramic teeth with plastic dentin porcelain, dry at 500°C for 5 minutes and place in a porcelain furnace. Under vacuum, the furnace is heated from 500°C to 925°C at a rate of 50°C / min. Vacuum sintering at ℃ for 15 minutes to obtain secondary treated metal porcelain teeth;

[0027] Step 4: After trimming the shape of the metal porcelain fused to metal teeth for the second treatment, pile plastic enamel porcelain on the surface and color it. After drying at 50...

Embodiment 2

[0030] A method for preparing metal-ceramic teeth, comprising the following steps:

[0031] Step 1: Prepare metal-ceramic inner crown;

[0032] Step 2: After plastic-shading porcelain is deposited on the surface of the inner crown, it is dried at 515°C for 7 minutes and then placed in a porcelain furnace. The furnace is heated from 515°C to 910°C at a heating rate of 61°C / min under vacuum. Vacuum sintering for 13 minutes to obtain metal-ceramic teeth treated at one time;

[0033] Step 3: After one-time treatment of metal-ceramic-fused-to-metal teeth with plastic dentin porcelain, dry it at 515°C for 4.5 minutes and place it in a porcelain furnace. The furnace is heated from 515°C to Vacuum sintering at 935°C for 13 minutes to obtain secondary treated metal-ceramic teeth;

[0034] Step 4: After trimming the shape of the metal porcelain fused to metal tooth for the second treatment, pile plastic enamel porcelain on its surface and color it. After drying at 515°C for 4.5 minute...

Embodiment 3

[0036] A method for preparing metal-ceramic teeth, comprising the following steps:

[0037] Step 1: Prepare metal-ceramic inner crown;

[0038] Step 2: After plastic-shading porcelain is deposited on the surface of the inner crown, it is dried at 530°C for 6 minutes and then placed in a porcelain furnace. The furnace is heated from 530°C to 905°C at a heating rate of 63°C / min under vacuum. Vacuum sintering for 14 minutes to obtain metal-ceramic teeth treated at one time;

[0039] Step 3: After one-time treatment of metal-ceramic teeth with plastic dentin porcelain, dry at 530°C for 4 minutes and place in a porcelain furnace. Under vacuum, the furnace is heated from 530°C to 928°C at a rate of 52°C / min. Vacuum sintering at ℃ for 14 minutes to obtain secondary treated metal porcelain teeth;

[0040] Step 4: After trimming the shape of the metal porcelain fused to metal teeth for the second treatment, pile plastic enamel porcelain on its surface and color it. After drying at 53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com