Detection device and method for cleaning loss rate of grain harvester

A detection device and detection method technology, applied in harvesters, counting mechanisms/items, agricultural machinery and implements, etc., can solve the problems of inability to quantitatively display the loss rate, low detection efficiency, imperfect technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

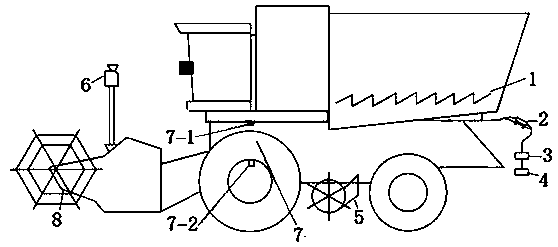

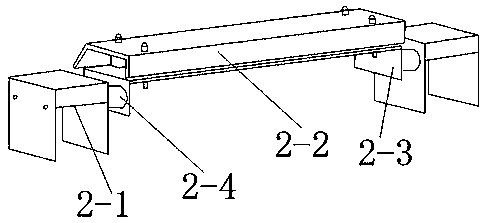

[0065] A grain harvester cleaning loss rate detection device, the device includes a feeding quality detection unit, a loss detection unit 2, a signal processing circuit 3 and a secondary instrument 4 wherein;

[0066] The feeding quality detection unit includes an image acquisition module 6, a magnet, a speed acquisition module 7 and a distance measuring sensor 8. The image acquisition module 6 is installed on the harvester and is shooting right above the plants to be harvested for obtaining grain Density, ranging sensor 8 is installed on the both sides of grain harvester grain divider, is used for obtaining the distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com