Truss-type filling method for underground mined-out area

A goaf, truss-type technology, applied in the fields of backfill, mining equipment, earth-moving drilling, etc., can solve the problems of increasing mining costs, large economic burden on mining enterprises, and insufficient tailings to fill goafs in mines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Take the gob filling of a lead-zinc mine in Gansu Province as an example:

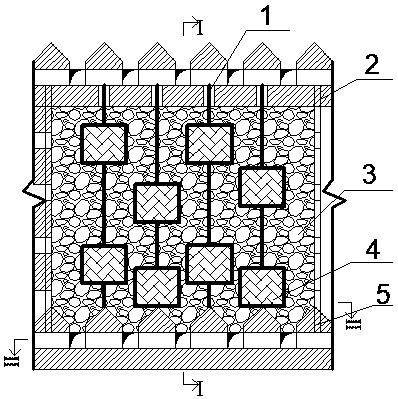

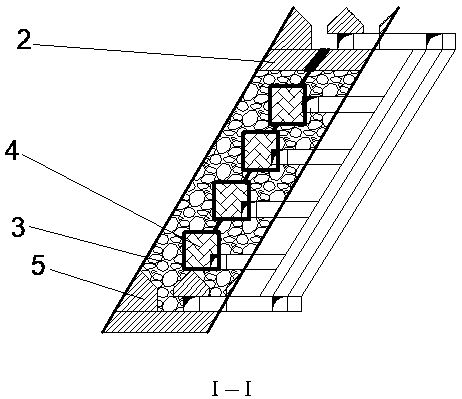

[0024] A truss-type filling method for underground goafs, comprising the following steps:

[0025] a. After eliminating the risk of rockfall and slabs in the goaf, clean up the stones at the drilling position of the goaf roof 2;

[0026] b. Carry out the drilling division in the form of plum blossom piles on the goaf roof 2;

[0027] c. On the drill hole position divided by step b, drill a drill hole 1 with a diameter of 400 mm, and the excavation depth of the drill hole 1 can be controlled to drill through the goaf roof;

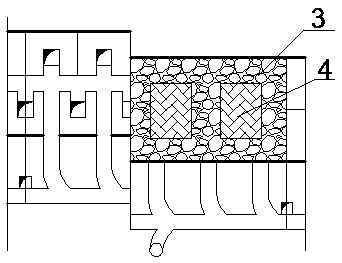

[0028] e. Lower a number of inner-tensioned rubber capsules 4 interconnected head to tail into the goaf through the borehole 1. Inject water into the 4 openings of the stretch rubber capsule;

[0029] d. After the inside of the rubber capsule body 4 of the inner tension rib is filled with water, pressurize the compressed gas of 0.7Mpa through the opening of the rubber caps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com