Liftable ballastless track structure and adjustment method thereof

A ballastless track and track slab technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problem of threatening the safe operation of high-speed railways, many railway speed limit stations, and it is difficult to meet large deformation and long duration in special areas Adjust demand and other issues to achieve the effect of saving operation and maintenance costs, reducing the number of outages and overhauls, and facilitating installation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

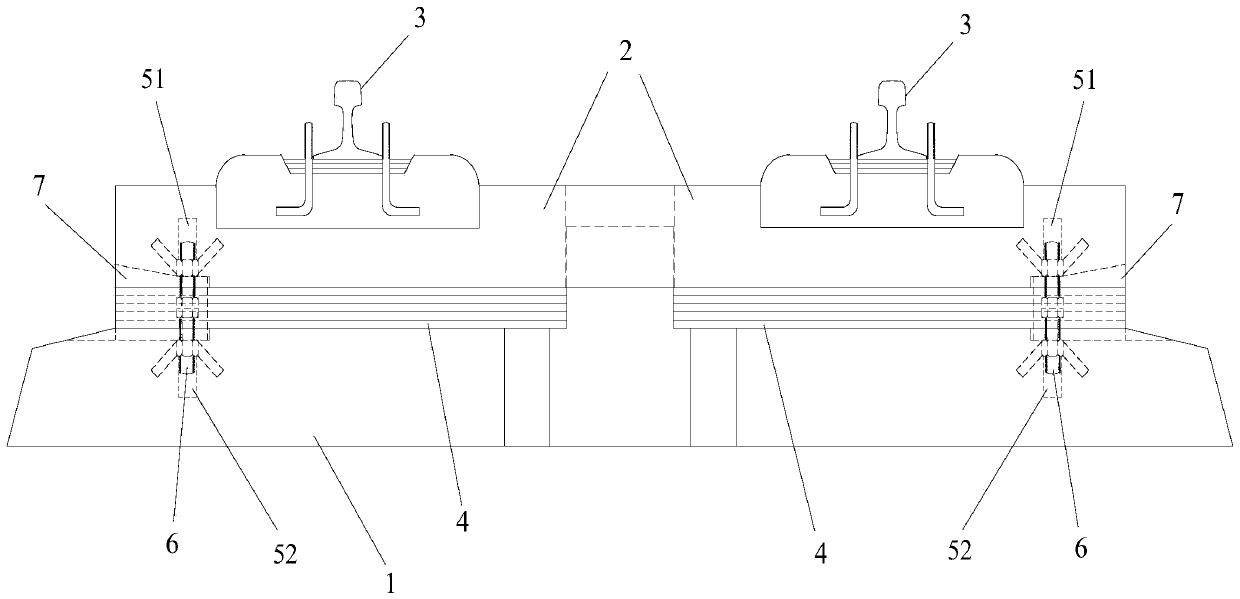

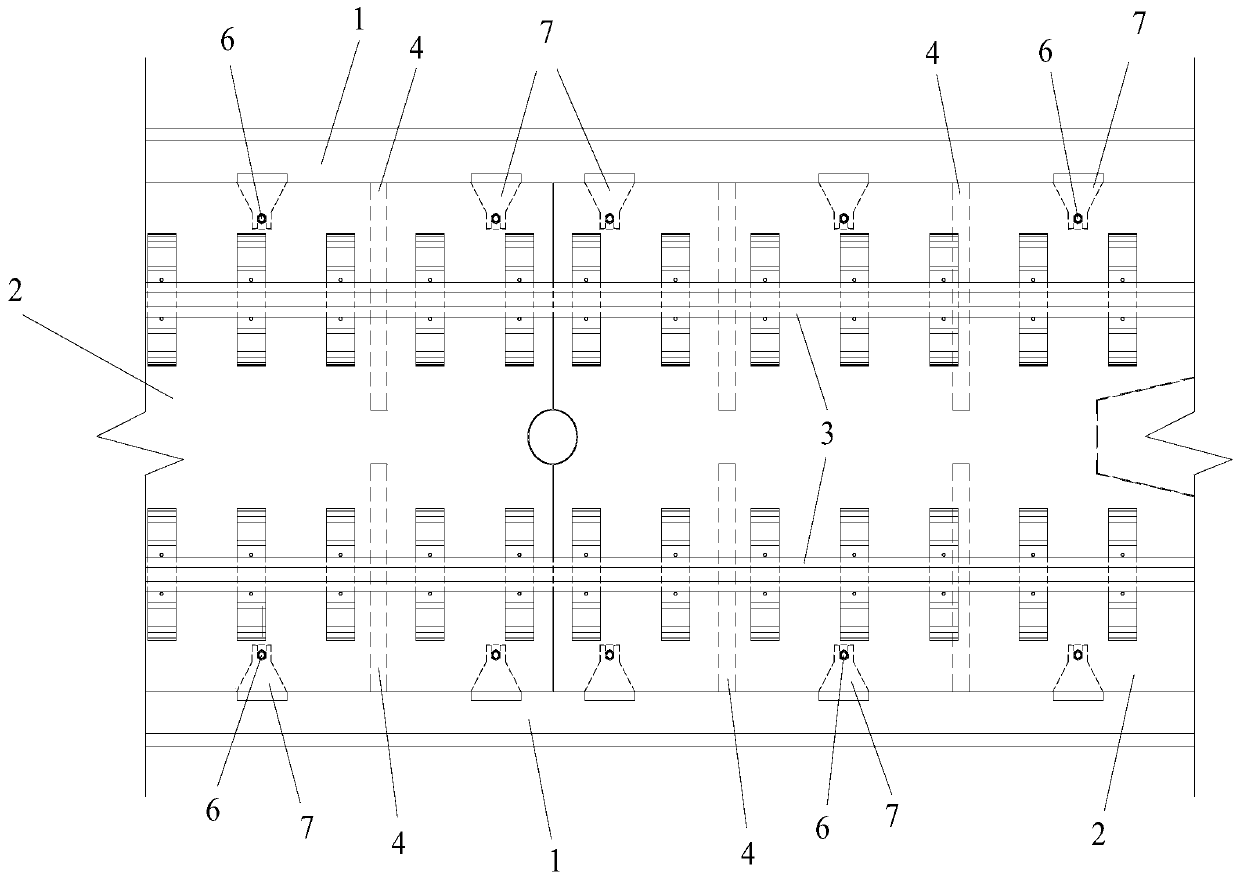

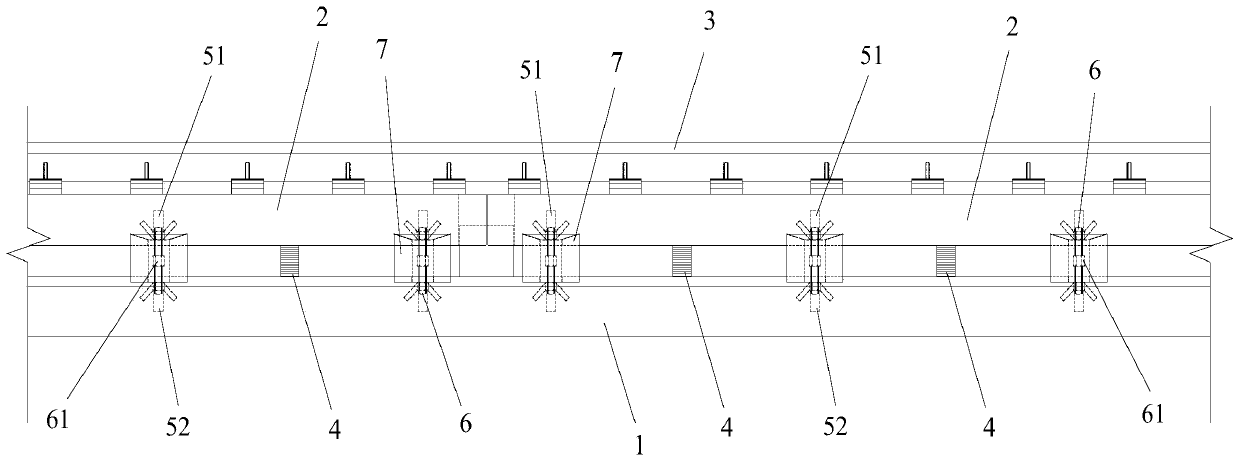

[0035] Such as Figure 1-3 As shown, a liftable ballastless track structure according to the present invention includes a base 1, a track plate 2 and two rails 3, and several track plates 2 are spliced to form an integral track plate, and the two rails 3 Set on the integral track plate.

[0036]Specifically, the bottom surface of each track plate 2 is provided with a vertical channel one 51, the opening of the channel one 51 is downward, and each channel one 51 is located on the outside of the rail 3, that is, away from the track One side of the center line of the plate 2, the top surface of the base 1 is provided with a vertical channel two 52, the opening of each channel two 52 is upward, and the shape and position of each channel one 51 are consistent with one of the channels. The shape and position of the second channel 52 are adapted, and the specific size and quantity are determined according to the design requirements. For example, each track plate 2 is provided with...

Embodiment 2

[0042] A method for adjusting a liftable ballastless track structure according to the present invention includes using a liftable ballastless track structure as described in Embodiment 1, comprising the following steps:

[0043] a. Take out the block 7 between the base 1 and the track plate 2;

[0044] b. When it is necessary to increase the elevation of the track plate 2, first turn the transmission rod 6 to raise the track plate 2 to 10-15mm higher than the target elevation, then make the height of the pad 4 meet the target elevation of the track plate 2, and then reverse Rotate the transmission rod 6 to lower the track plate 2 to the target elevation, and abut against the top surface of the pad 4; The track plate 2 rises, and then the height of the spacer 4 meets the target elevation of the track plate 2, and then the transmission rod 6 is reversely rotated to lower the track plate 2 to the target elevation, and the spacer 4 is connected to the target elevation. top abutme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com