Automatic check-in weighing and conveying machine

A conveyor and check-in technology, applied in conveyors, conveyor objects, weighing, etc., can solve the problems of large motor vibration, decreased weighing accuracy, inaccurate weighing data, etc., and achieve the weighing data. Accurate, easy to make, easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

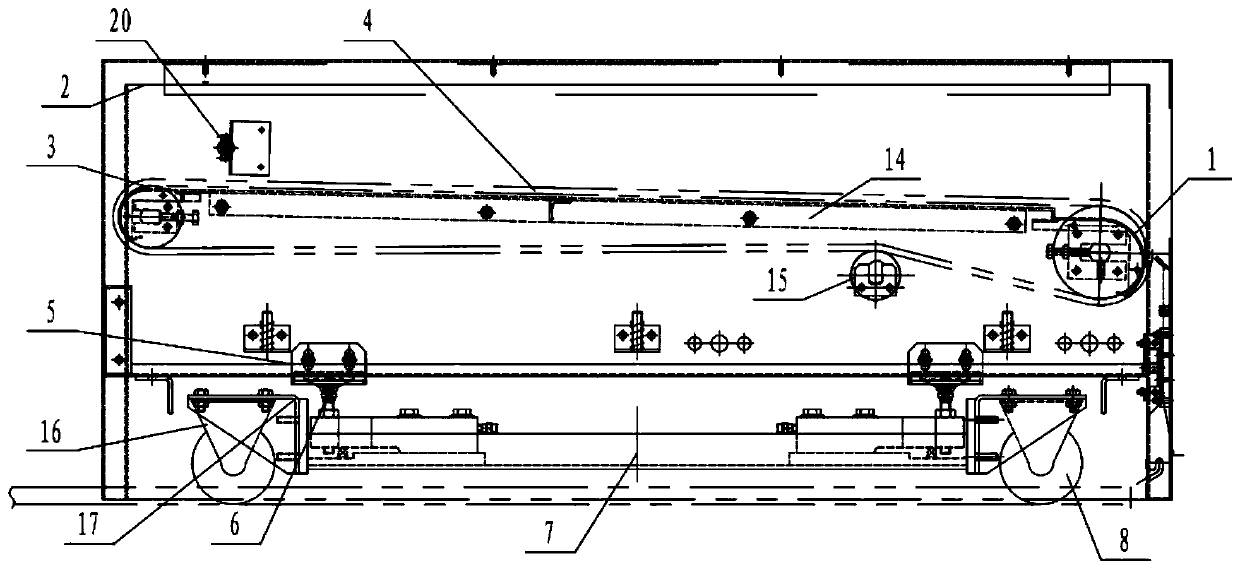

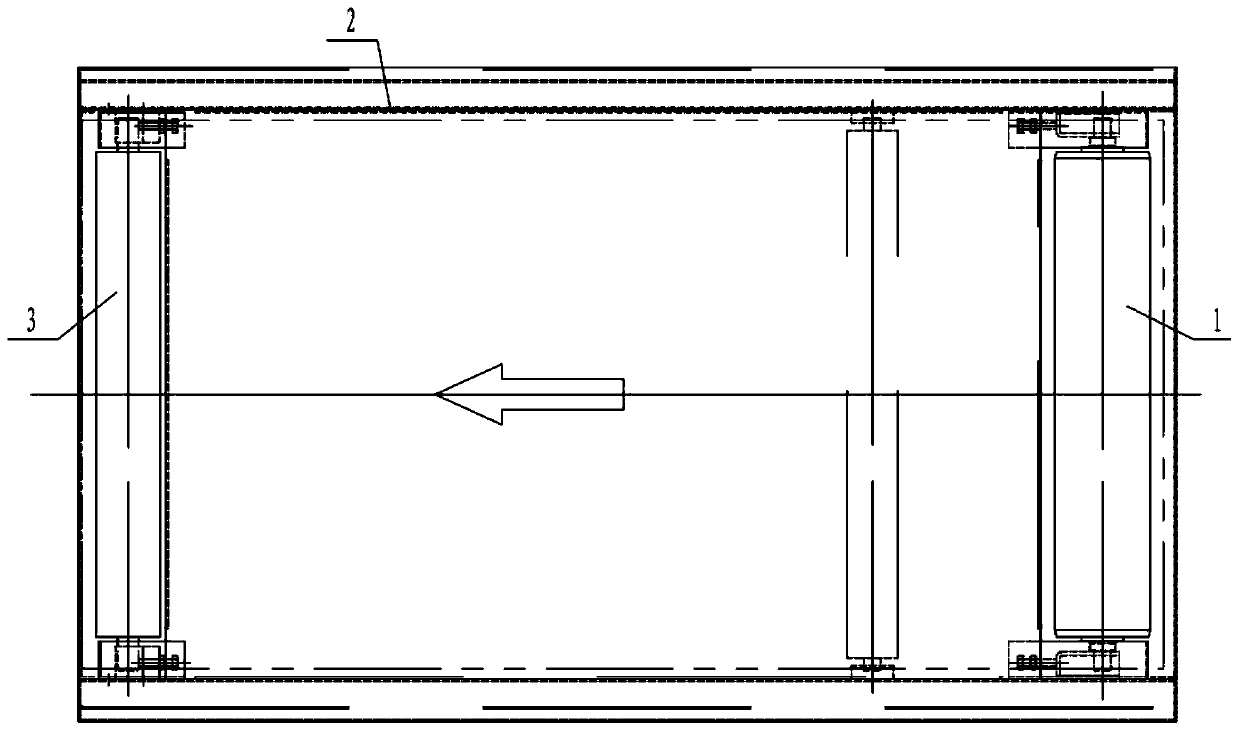

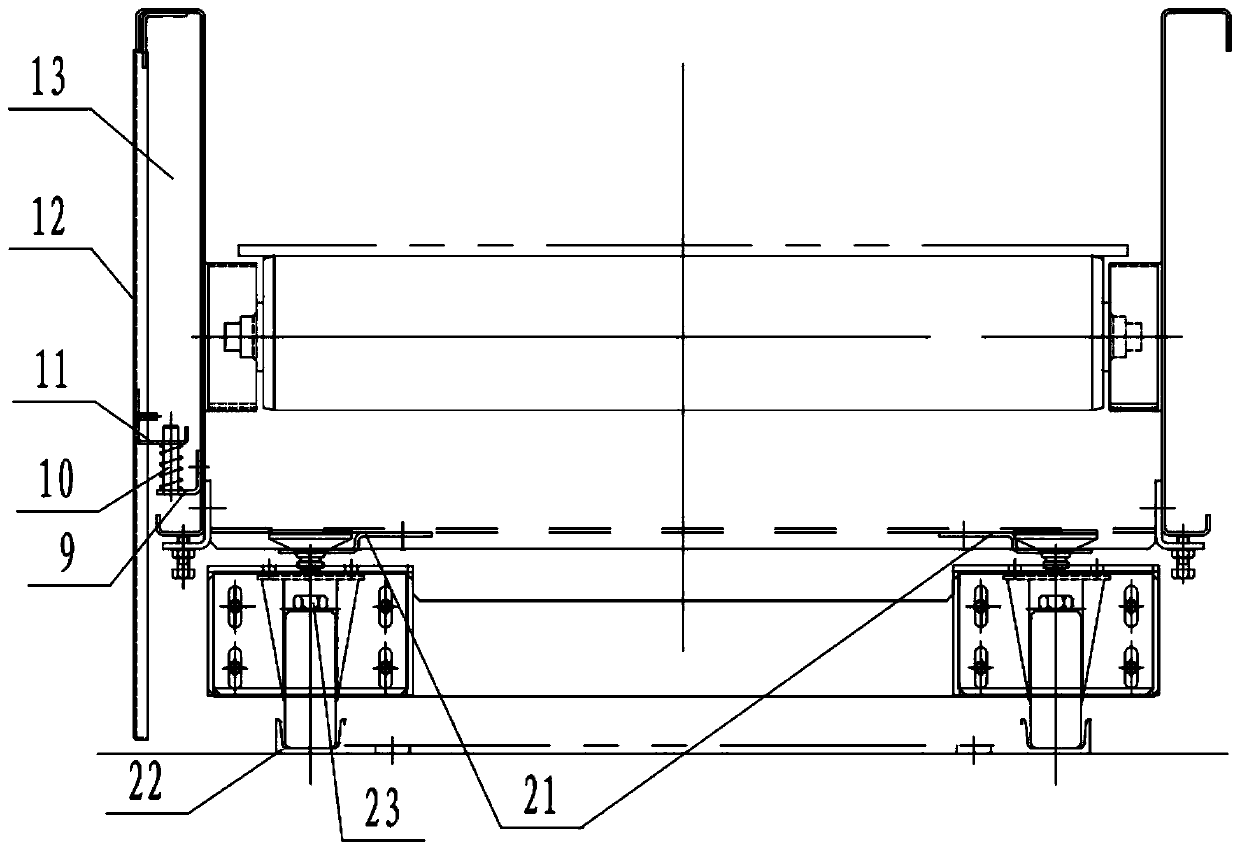

[0028] Embodiment 1: as Figure 1-5 As shown, an automatic check-in weighing conveyor includes a conveyor and a weighing device. The conveyor includes a motorized roller 1, a frame 2, a non-powered roller 3 and a belt 4, and the motorized roller 1 and a non-powered roller 3 Installed on both ends of the frame 2 respectively, the belt 4 is sleeved on the electric drum 1 and the unpowered drum 1 3, the lower end of the frame 2 is fixedly connected to four symmetrical scale supports 5, and the four scale supports 5 are placed on four On the scale supporting legs 6, four weighing scale supporting legs 6 are fixedly connected to the top four corners of the weighing device 7, four casters 8 are installed at the bottom of the four corners of the weighing device 7, and the four casters 8 are placed in the guide rail groove 22, and the guide rail groove 22 It is fixedly connected on the ground, and after the equipment is installed, the four casters 8 are fixedly connected to the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com