A kind of feeding equipment for packing box forming machine

A technology of feeding equipment and molding machine, which is applied in the field of carton transmission, and can solve problems such as easy slipping out of the expected position and unavailable items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

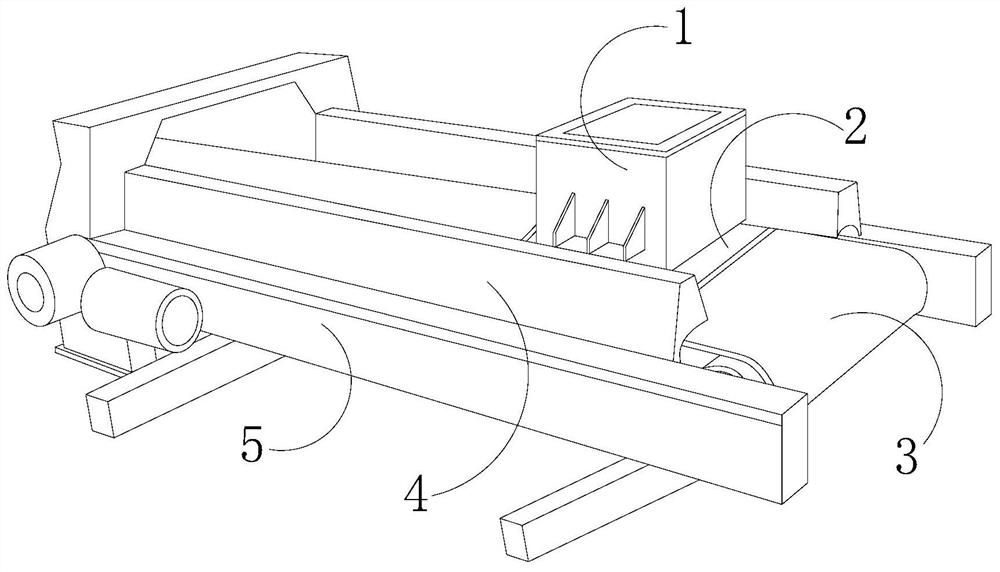

[0024] See Figure 1 - Figure 6 The present invention provides a packaging cartridge forming machine feed apparatus including the item lamination chamber 1, a pre-table 2, a transmission belt 3, a paper 4, a fixing frame 5, and the article deserved 1 is located in the precipitial table 2 is northern Up, the predetermined stage 2 is mounted on the transmission belt 3, the paper plate 4 is provided with two parallel structures, and the transmission belt 3 is disposed between the two panels 4, the fence 4 and the fastener 5 Mechanical welding;

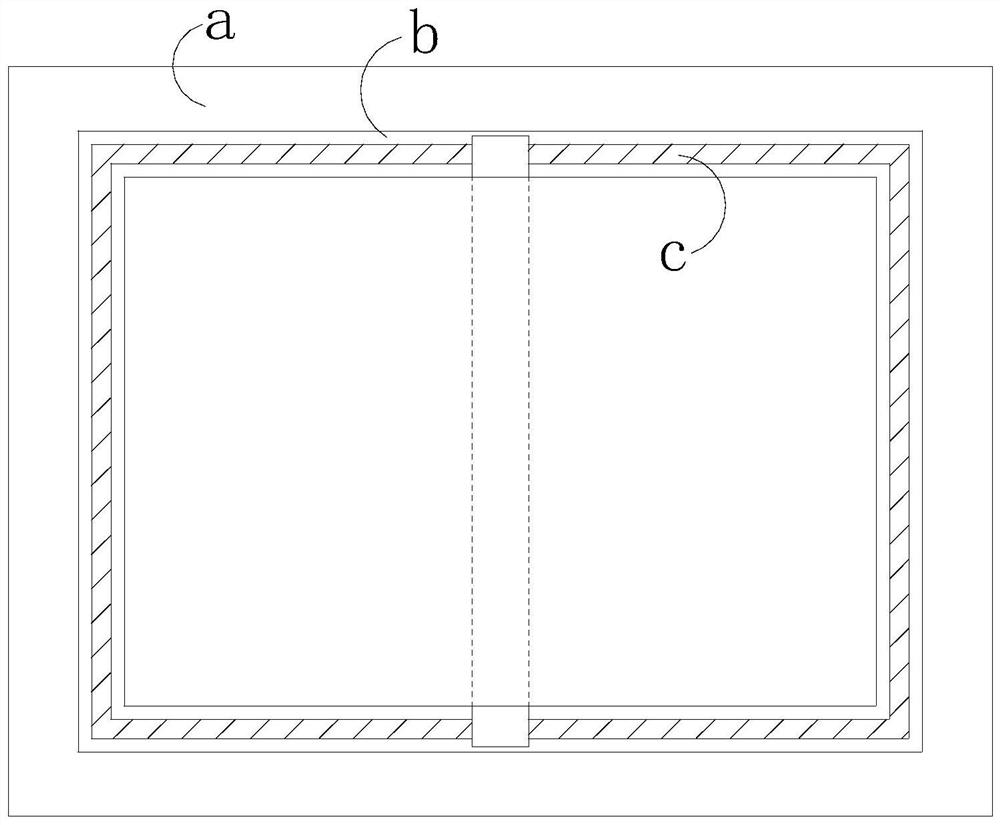

[0025] The predetermined stage 2 is configured by the fixing plate A, the rectangle groove B, the limit device C, and a rectangular groove B is provided on the center of the fixed plate A, and the rectangular groove B will be fixed. The board A is running, and the limit device C is mounted in the rectangular groove B, and the limit device C is fitted to the rectangular groove B.

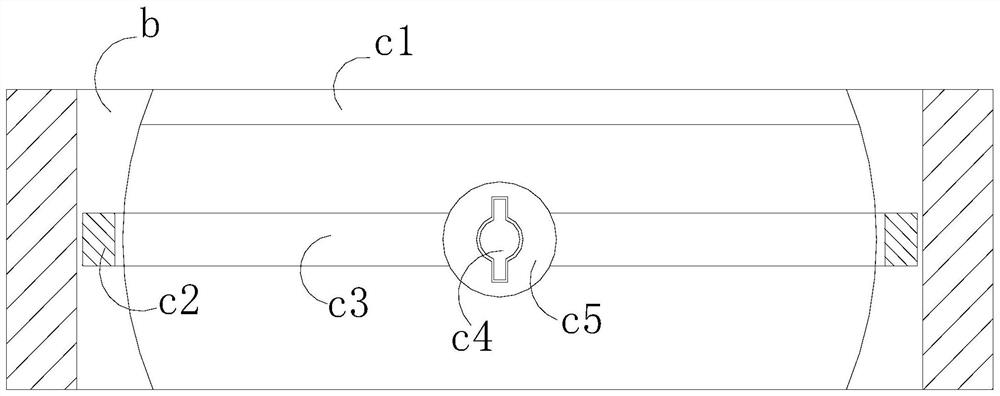

[0026] The limiting device C is composed of a discharge plate C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com