A method for detecting organic solvent content in mixed solution

A technology of organic solvents and mixed solutions, applied in measuring devices, transmittance measurement, instruments, etc., can solve the problems of high cost, long detection time, and inability to realize real-time detection, and achieve low cost, real-time and accurate detection, and simple method Fast and Intuitive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

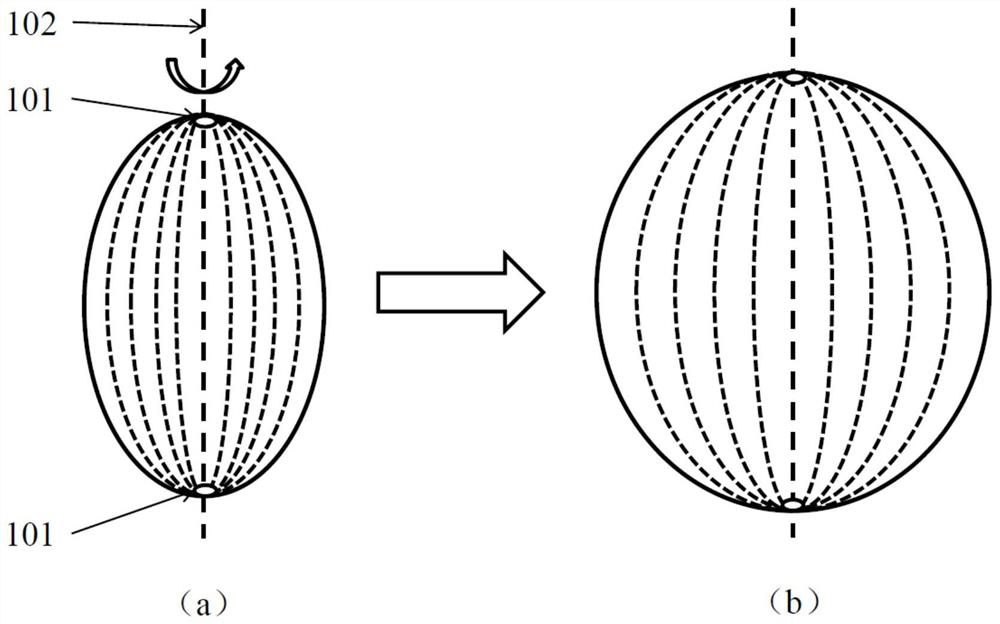

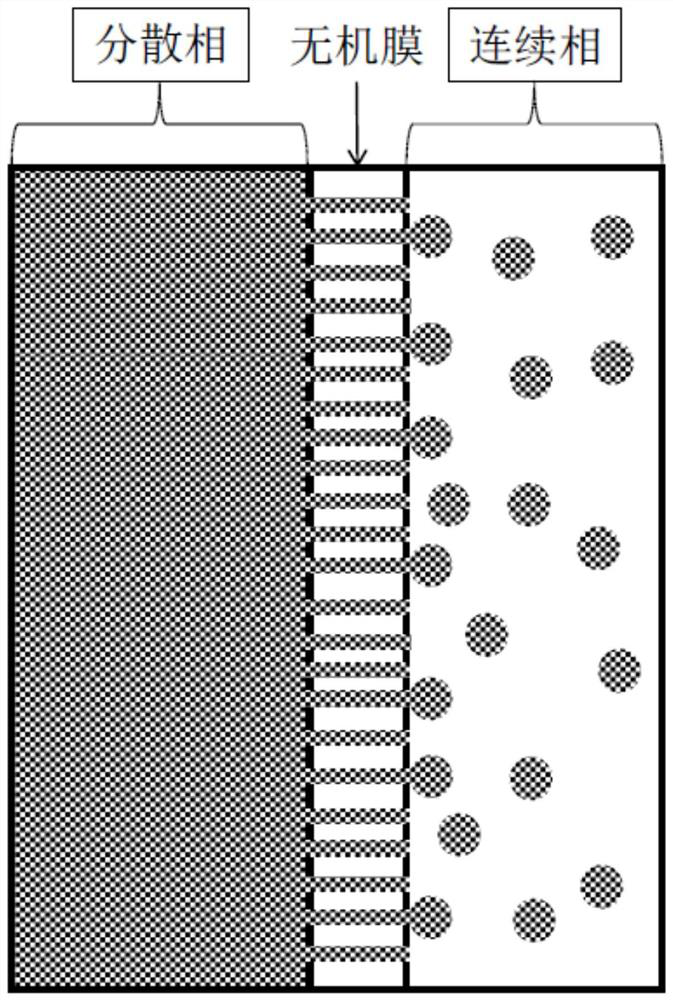

Method used

Image

Examples

Embodiment 1

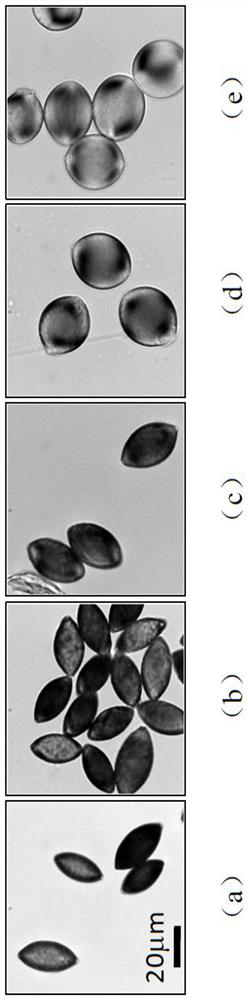

[0046] Preparation contains 1g reactive liquid crystal RM257, 9g non-reactive liquid crystal 5CB and 100mg photoinitiator DMPAP liquid crystal mixture (reactive liquid crystal RM257 accounts for the mass percent of liquid crystal mixture is 9.9%), it is made into polymer ellipse according to the above steps The sphere, wherein the micropore diameter of the SPG film is 10 microns, the liquid crystal conformation changing agent is Pluronic, the continuous phase is water, and the mass percent concentration of the liquid crystal conformation changing agent in water is 1%. Such as image 3 As shown, the mixed solution of polymer ellipsoid in different concentrations of tetrahydrofuran and deionized water (the volume percentage of tetrahydrofuran is a: 0%, b: 25%, c: 50%, d: 75%, e: 100%) have different swelling structures. At the same time, it can be seen from the figure that with the increase of THF content, the long diameter of the polymer ellipsoid basically remains unchanged, ...

Embodiment 2

[0048] Preparation contains 1g reactive liquid crystal RM257, 9g non-reactive liquid crystal 5CB and 100mg photoinitiator DMPAP liquid crystal mixture (reactive liquid crystal RM257 accounts for the mass percent of liquid crystal mixture is 9.9%), it is made into polymer ellipse according to the above steps Ball, wherein the micropore diameter of SPG film is 20 microns, the liquid crystal conformation changing agent is PVP, the continuous phase is glycerol / water (9:1) solution, and the mass percentage concentration of the liquid crystal conformation changing agent in the continuous phase is 1%. The structure of the polymer ellipsoid in the dry state is as follows Figure 5 The SEM image is shown. Similarly, the polymer ellipsoid has different swelling structures in the mixed solutions of different proportions of THF and deionized water, and the relationship curve of its average aspect ratio to the content of THF in the mixed solution is as follows Image 6 shown. It can be s...

Embodiment 3

[0050] Liquid crystal mixtures containing reactive liquid crystal RM257, non-reactive liquid crystal 5CB and 100 mg photoinitiator DMPAP were prepared respectively. The total mass of liquid crystals of RM257 and 5CB was 10 g, and the percentages of RM257 to the total mass of liquid crystals were 10%, 30%, and 40% respectively (reactive liquid crystal RM257 accounts for 9.9%, 29.7%, 39.6% of the mass percent of liquid crystal mixture respectively), it is made into polymer ellipsoid according to the above steps, wherein the SPG film pore diameter is 10 microns, and the liquid crystal conformation changing agent It is Pluronic, the continuous phase is water, and the mass percent concentration of the liquid crystal conformation changing agent in the continuous phase is 1%. Similarly, polymer ellipsoids with different degrees of crosslinking (that is, the percentage of reactive liquid crystal RM257 in the total mass of liquid crystal) have different swelling structures in mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com