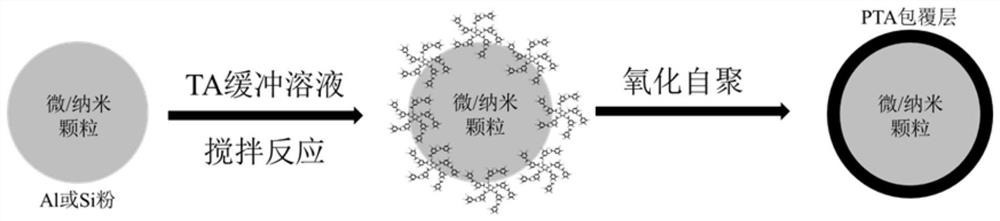

Preparation method of polymerized tannic acid coated high-activity aluminum powder/silicon powder

A tannic acid, high-activity technology, applied in the direction of offensive equipment, compressed gas generation, non-explosive/non-thermal agent components, etc., can solve the problems that are not suitable for industrial production applications, high equipment requirements, and low output, and achieve the goal of containing Rich in carbon, low equipment requirements, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.22 g of TRIS buffer reagent was dissolved in a methanol / N, N-dimethylformamide solvent of 100 mL of a volume ratio of 1: 1, adjusted pH to 8.5, and then 0.20 g tanning acid (TA), stirred and dissolved A tannic acid-buffer solution was obtained; 0.10 g of nano-aluminum powder was added, stirred from polymerization reaction for 1 h, filtered, washed, and obtained polymerized tanninic acid coated nano-aluminum powder.

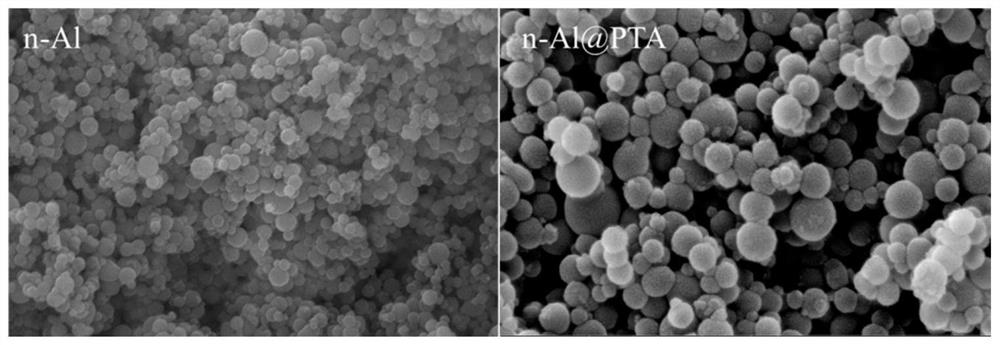

[0029] figure 2 with Figure 4 The SEM and TEM diagrams of nano-aluminum powder coated with nano-aluminum powder and a polymerized tanninic acid obtained in the present embodiment, compared that polymerized tannic acid has been formed in a nano-aluminum powder surface. Figure 6 For nano-aluminum powder and the XRD diagram of the polymerized tannin-coated nano-aluminum powder prepared in the present embodiment, the contrast can be found that aluminum peaks are obvious, and the polymerized tannin has no aluminum powder after coating nano-aluminum powder. Natu...

Embodiment 2

[0031] 0.22 g of TRIS buffer reagent was dissolved in a methanol / N, N-dimethylformamide solvent of 100 ml of a volume ratio of 1: 1, adjusted pH to 9.6, then add 0.20 g tanning acid (TA), stirred and dissolved. A tannic acid-buffer solution was obtained; 0.10 g Nano silica powder was added, stirred from polymerization reaction for 6 h, filtered, washed, and obtained nano-silica powder coated polymerized tannic acid.

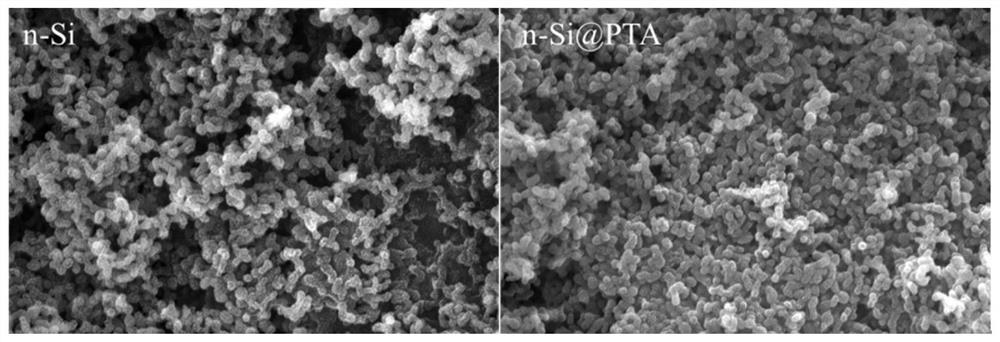

[0032] image 3 with Figure 5 The polymerized tanninic acid obtained by nano-silica powder and the present embodiment, respectively, the SEM and TEM photograph of nano-silica powder, comparison, polymerized tannic acid has been formed uniformly in the surface of the nanowoxic powder. Figure 7 The XRD diagram of the polymerized tannic acid obtained by nano-silica powder and the present invention, the contrast can be found that the silicon peaks are obvious, and the polymerized tannic acid is covered with nano-silicon powder and did not change the silicon powder The ...

Embodiment 3

[0034] 0.22 g of TRIS buffer reagent was dissolved in a methanol / N, N-dimethylformamide solvent of 100 mL of a volume ratio of 1: 1, adjusted pH to 8.5, and then 0.20 g tanning acid (TA), stirred and dissolved A tannic acid-buffer solution was obtained; 0.10 g of micron aluminum powder was added, stirred from polymerization reaction for 1 h, filtered, washed, to obtain a polymerized tannic acid coated micron aluminum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com