Hoisting method of heavy rolling mill arch in confined space

A rolling mill archway and limited space technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem that the lifting weight and lifting height of the crane cannot meet the hoisting requirements of the heavy rolling mill archway, and the size of the large hot-rolled strip rolling mill archway is large , heavy-duty rolling mill archway and other problems, to achieve the effect of safe and reliable sliding process, safe and reliable hoisting process, and low hoisting height requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated below by specific examples.

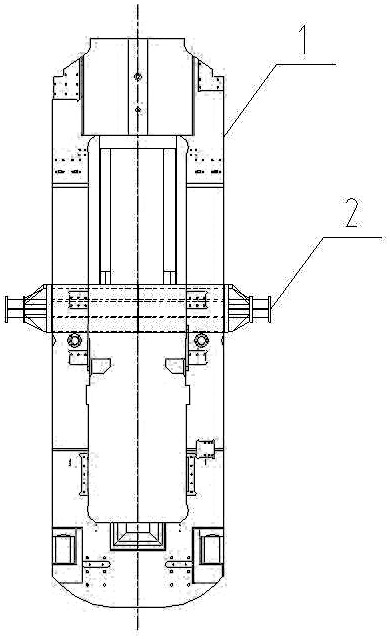

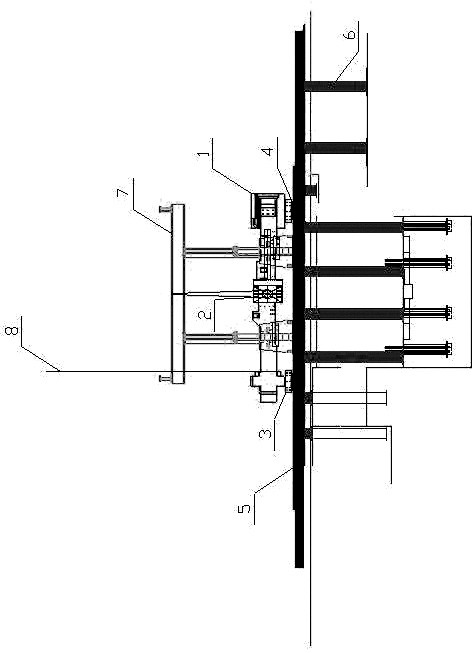

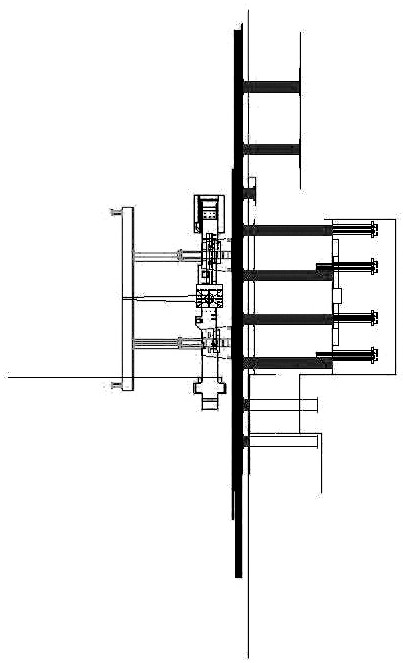

[0026] like Figure 1~Figure 5 As shown, a hoisting method for a heavy rolling mill arch in a confined space, including

[0027] (1) Construction preparation; including fabrication and installation of sliding track, fabrication and installation of sliding device, etc.; said sliding track includes support pier 6, track beam 5, and said sliding device includes sliding beam 3 and roller 4;

[0028] (2) Unloading of the heavy rolling mill arch and installing the spreader; use the hydraulic gantry crane 7 to unload the heavy rolling mill arch 1, hoist it to the sliding beam 3, and install the spreader 2;

[0029] (3) The heavy-duty rolling mill archway slides in place; hang the chain down on the longitudinal lugs of the sliding beam 3, so that the heavy-duty rolling mill archway 1 can slide in place at one time, and use 4 hydraulic jacks to jack up the heavy-duty rolling mill archway 1 and lift it up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com