Passive bending axial rotation mechanism based on cambered surface free ends and three-reed crossed reeds

A technology of axial rotation and free end, applied in the direction of non-rotating propulsion elements, etc., can solve the problem of passive deformation of bionic fish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

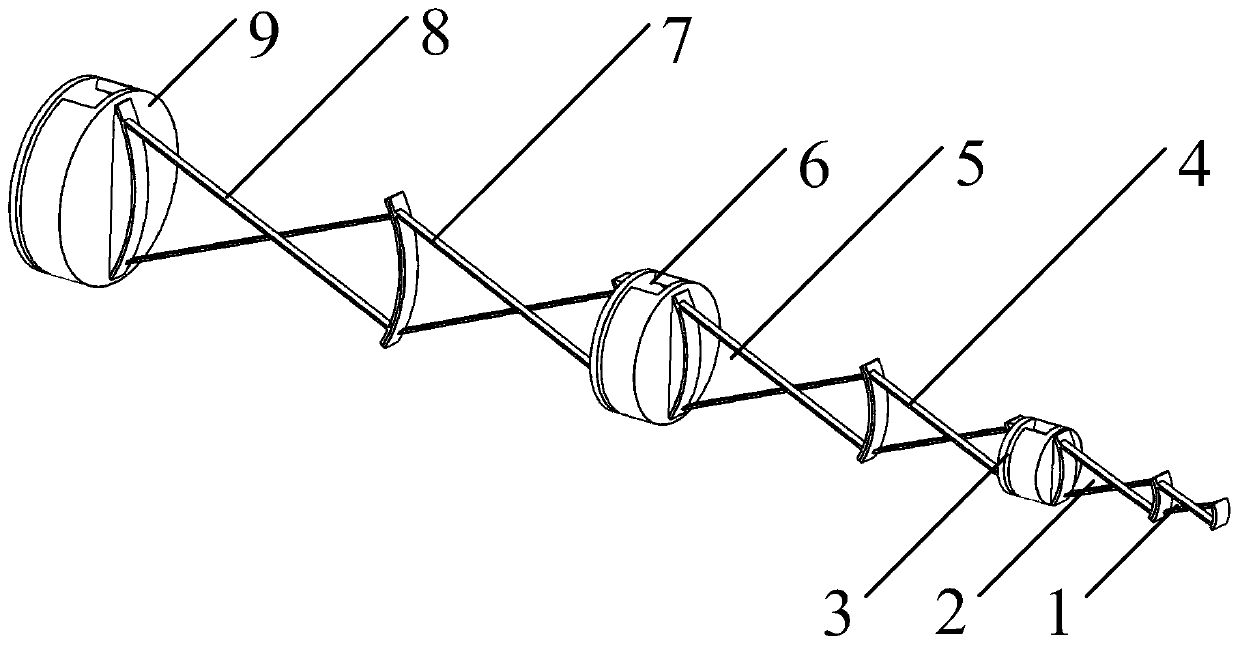

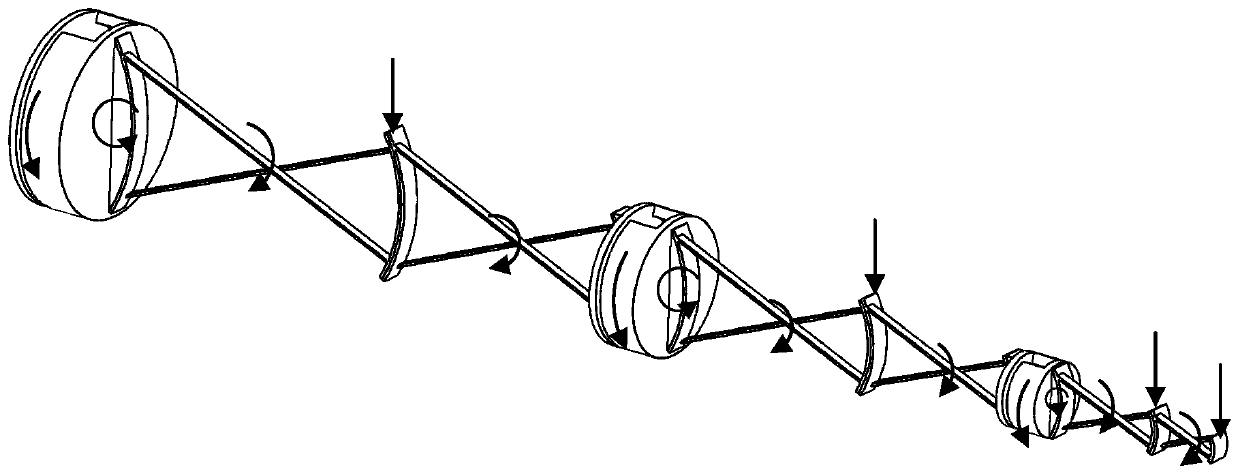

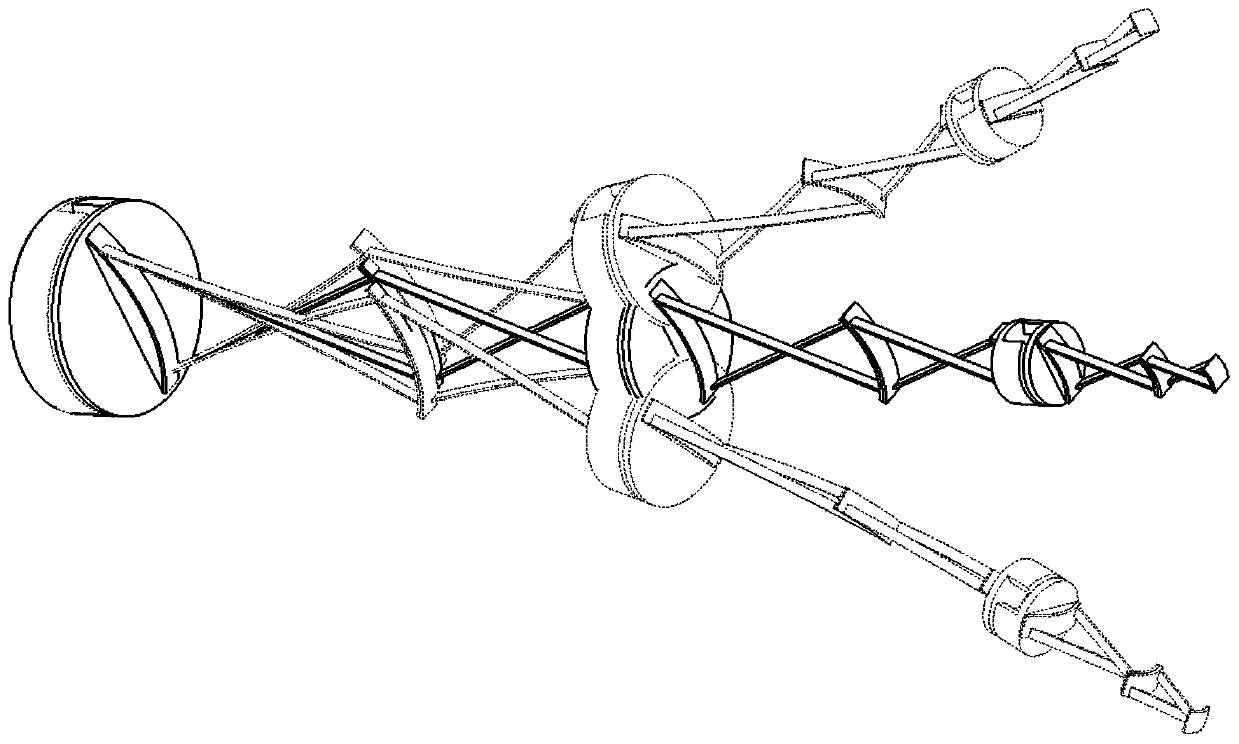

[0034] The overall structure of the embodiment of the present invention is shown in schematic figure 1, with six levels of cross reeds and three axially rotating cross reed units; the mechanism shown in the figure, the two ends of the cross reed that undertakes the bending task are connected to the free ends of the arc surface, and the two-stage bending cross reed units An axially rotating cross-reed unit is connected between them, and they are distributed according to the order: No. 1 curved cross-reed unit 1 connects to No. 2 curved cross-reed unit 2, and then connects to No. 1 axially-rotating cross-reed unit 3 , connect the No. 3 curved cross reed unit 4 and the No. 4 curved cross reed unit 5 in turn, then connect the No. 2 axially rotating cross reed unit 6, and connect the No. 5 curved cross reed unit 7 and No. 6 in turn No. bending cross reed unit 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com