An adsorption type easy-to-clean plate and frame air filter element

An air filter and adsorption technology, applied in the field of adsorption-type easy-to-clean plate-and-frame air filter, can solve the problems of difficult cleaning of plate-and-frame dust filter and poor purification effect of tiny particles of dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

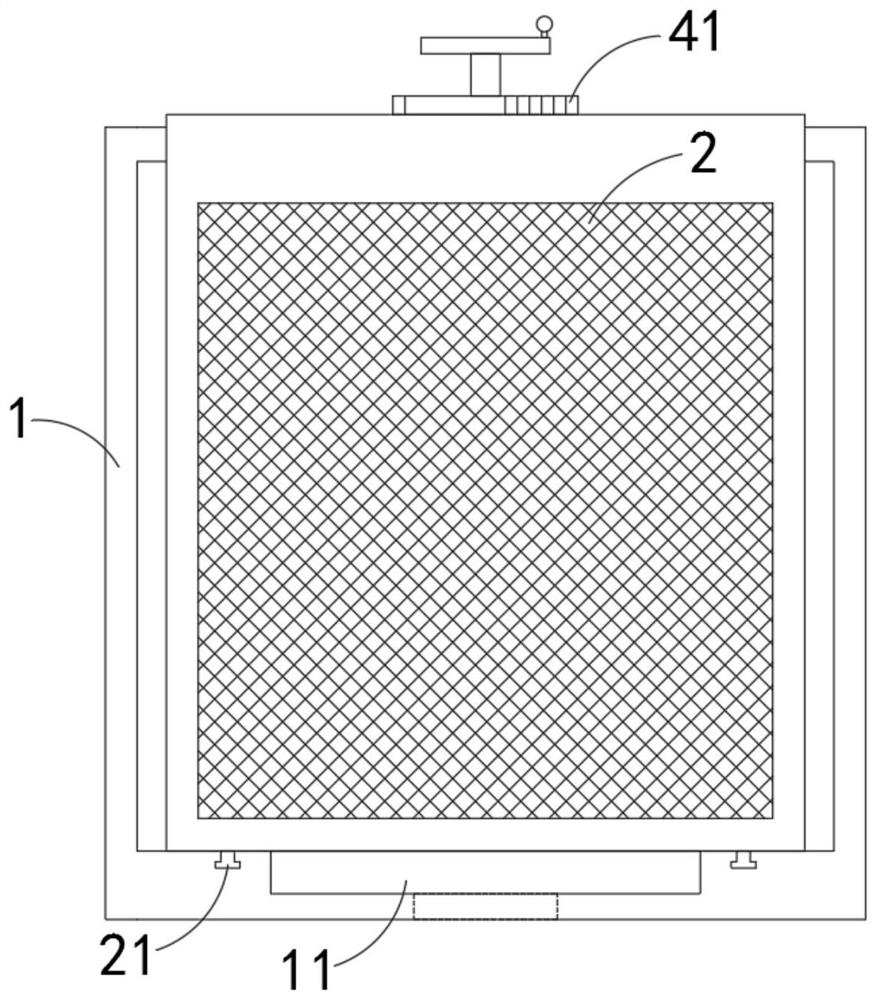

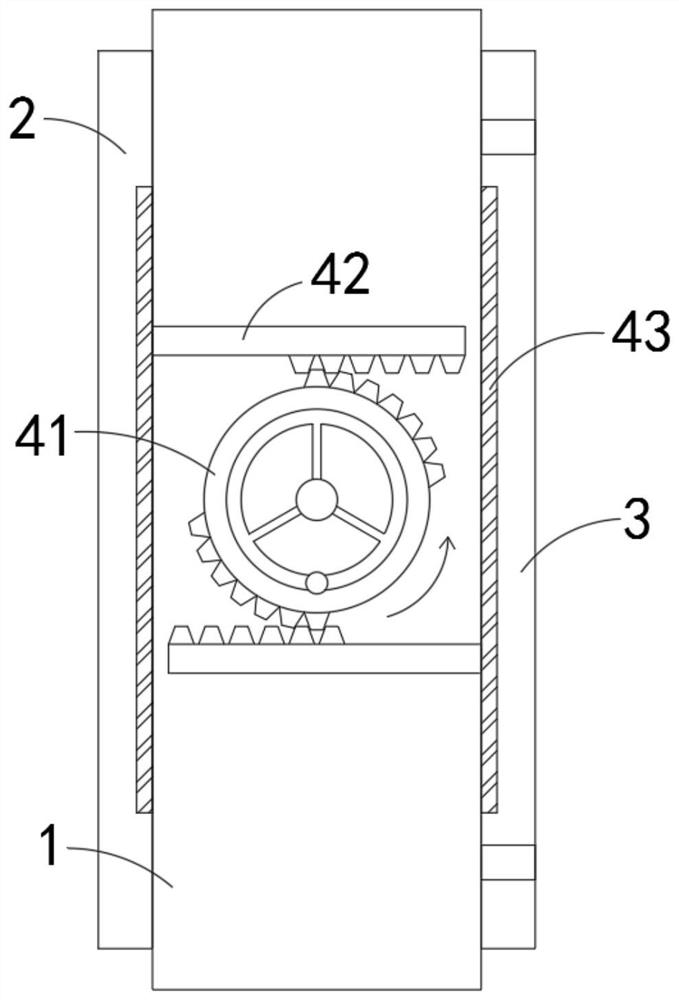

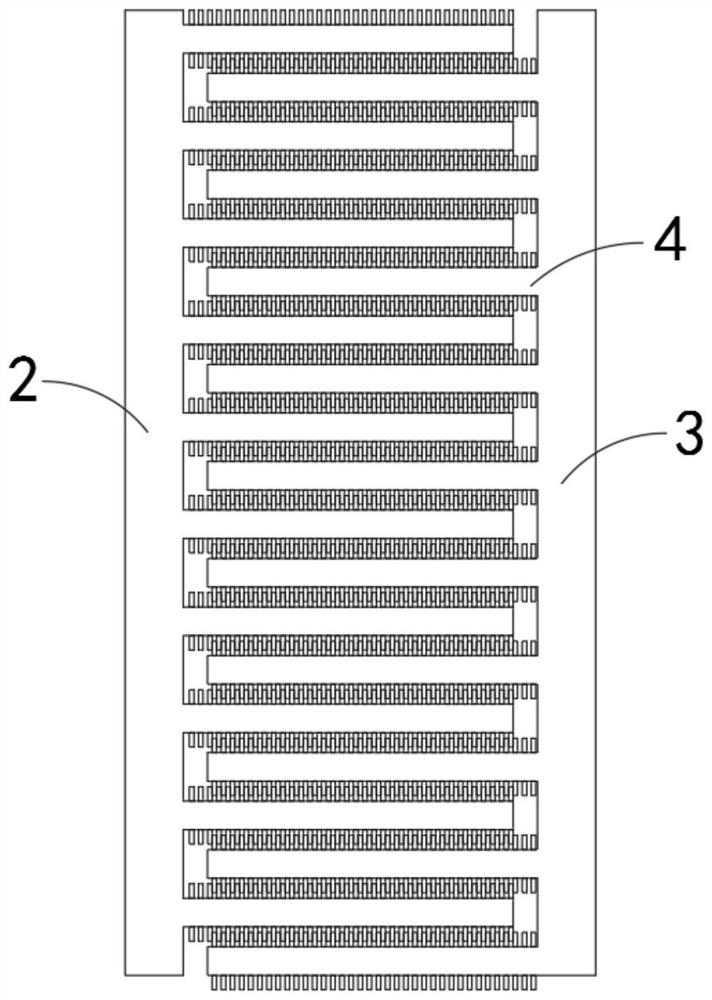

[0021] like Figure 1-3 As shown, an adsorption-type easy-to-clean plate-frame air filter element includes a frame body 1, and front and rear mesh panels 3 are slidably connected to the front and rear sides of the frame body 1. Specifically, the lower ends of the front mesh plate 2 are Both sides are fixedly connected with sliding bars 21, and the inner bottom surface of the frame body 1 is provided with sliding grooves corresponding to the sliding bars 21. The side wall opposite to the rear screen 3 is evenly provided with a plurality of fan dust filter plates 4, the dust filter plates 4 on the front screen 2 and the dust filter plates 4 on the rear screen 3 are arranged alternately, and the dust filter plates 4 are evenly provided with Dust-collecting velvet, it should be noted that the distance between two adjacent dust filter plates 4 is the same as the length of the dust-collecting velvet, so that the dust-collecting velvets on the adjacent two dust filter plates 4 are st...

Embodiment 2

[0026] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that both sides of the ash collecting tank 11 are fixedly connected with a friction bar 22 in contact with the sliding bar 21, and the friction bar 22 is located on the side wall of the ash collecting tank 11. The conductive plate 23 is fixedly connected. It should be noted that the contact surface of the sliding bar 21 and the friction bar 22 can adopt materials that generate more static electricity. For example, the sliding bar 21 and the friction bar 22 on the left can use silk layer and glass respectively Layer, slide bar 21 and friction bar 22 that are positioned at the right side can adopt fur layer and rubber layer respectively, make the conductive plate 23 of left and right side have positive charge and negative charge respectively, strengthen the adsorption capacity to different dust particles, conduct electricity The upper end of plate 23 is fixedly connected with discharge tip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com