Telescopic comb

A comb and telescopic component technology, which is applied to hair combs, clothing, hairdressing equipment, etc., can solve the problems of inability to flexibly adjust the length of the comb, the comb cannot be adjusted, and the structure is fixed, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

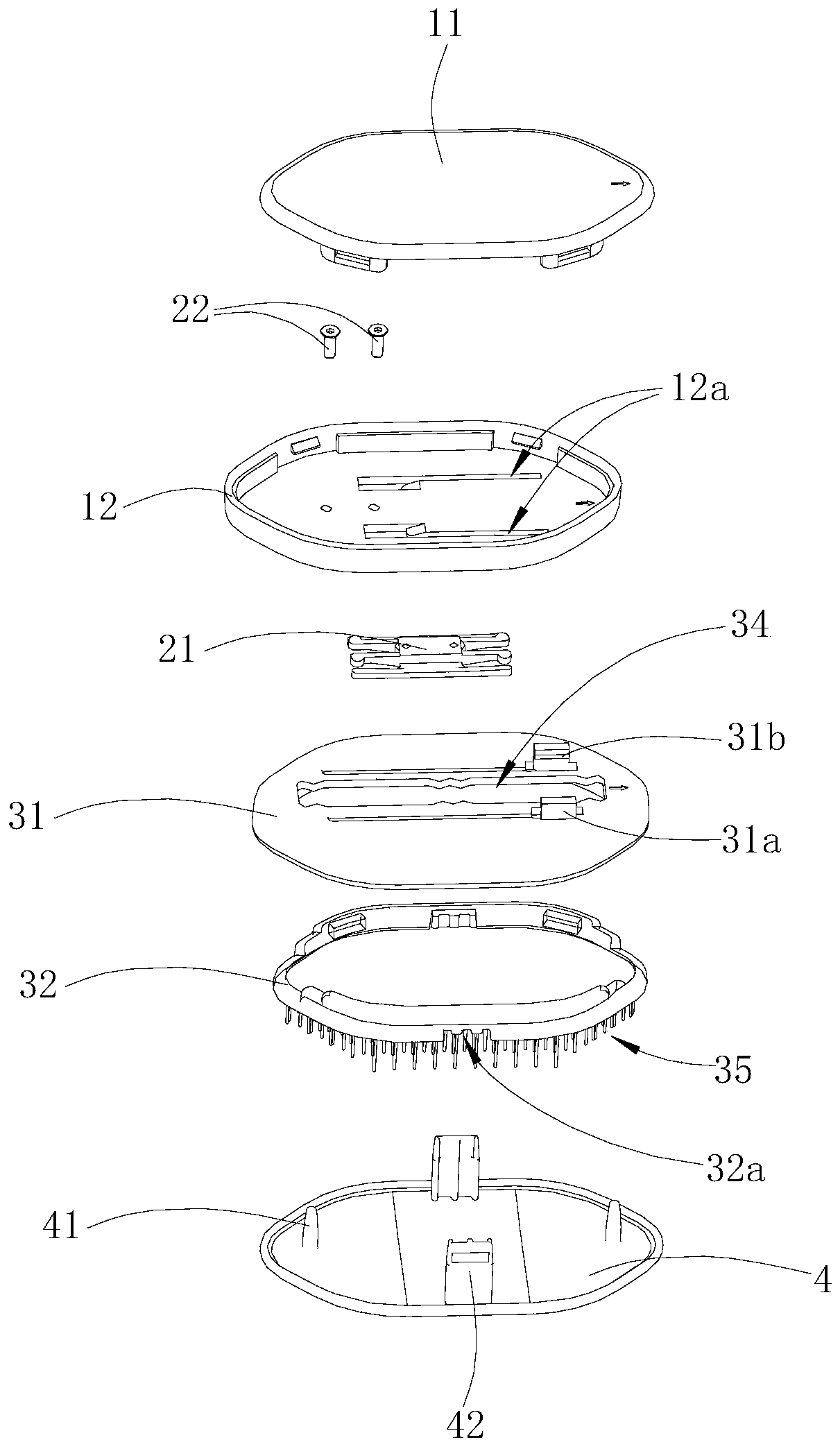

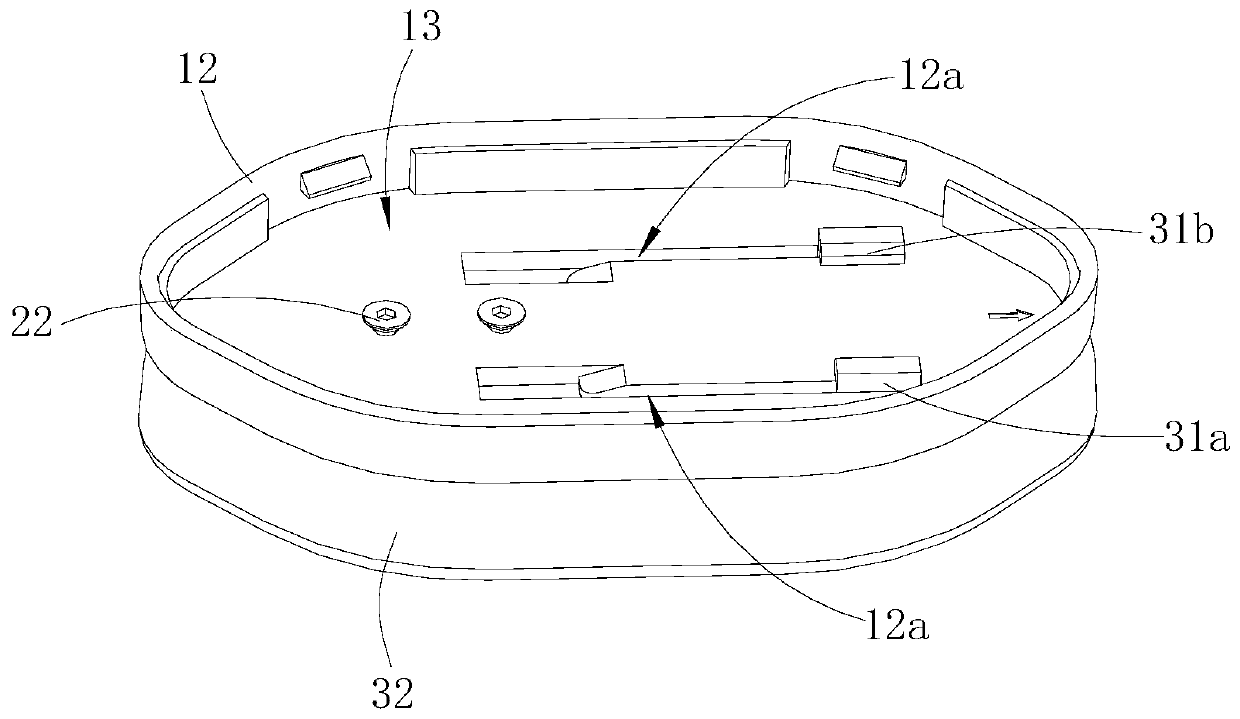

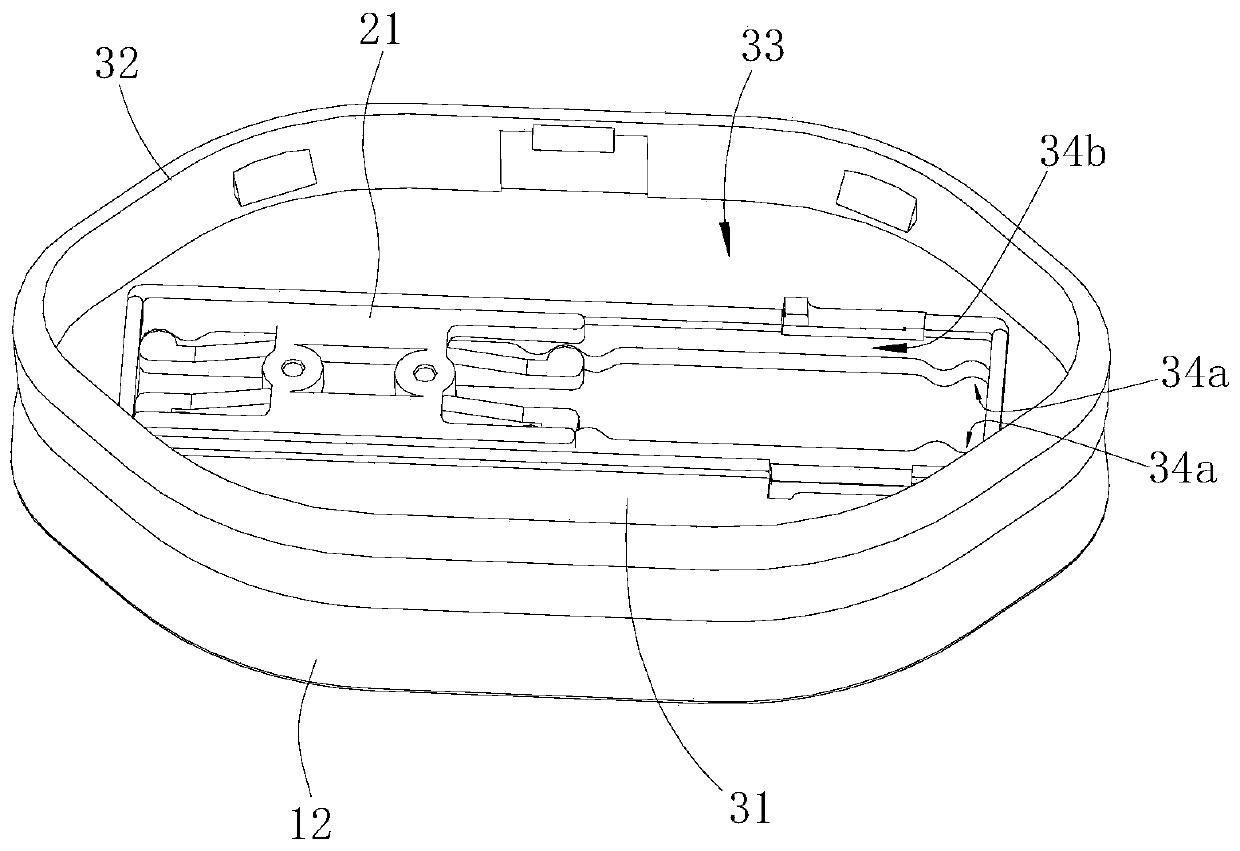

[0019] Such as Figures 1 to 5 As shown (in order to observe the situation inside the lower comb, Figures 2 to 4 The bottom plate area and bristles of the lower housing 32 are omitted in the figure).

[0020] The telescopic comb comprises an upper cover part, a lower comb part, a protective plate 4 and a telescopic assembly.

[0021] The upper cover part includes an upper cover plate 11 and an upper case 12, the upper cover plate 11 is located on the upper side of the upper case 12, the upper case 12 is connected with the upper cover plate 11, and a second A cavity 13, two positioning grooves 12a communicated with the first cavity 13 are formed on the lower end surface of the upper casing 12 of the upper cover part, and the direction of the positioning grooves 12a is consistent with the length direction of the sliding seat 21.

[0022] The telescoping assembly includes a sliding seat 21 and two fixing bolts 22. The sliding seat 21 is fixed on the lower side of the upper cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com