Production method of non-fried baked bean curd skin

A production method, non-fried technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of low soybean utilization rate, difficulty in ensuring taste and flavor, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

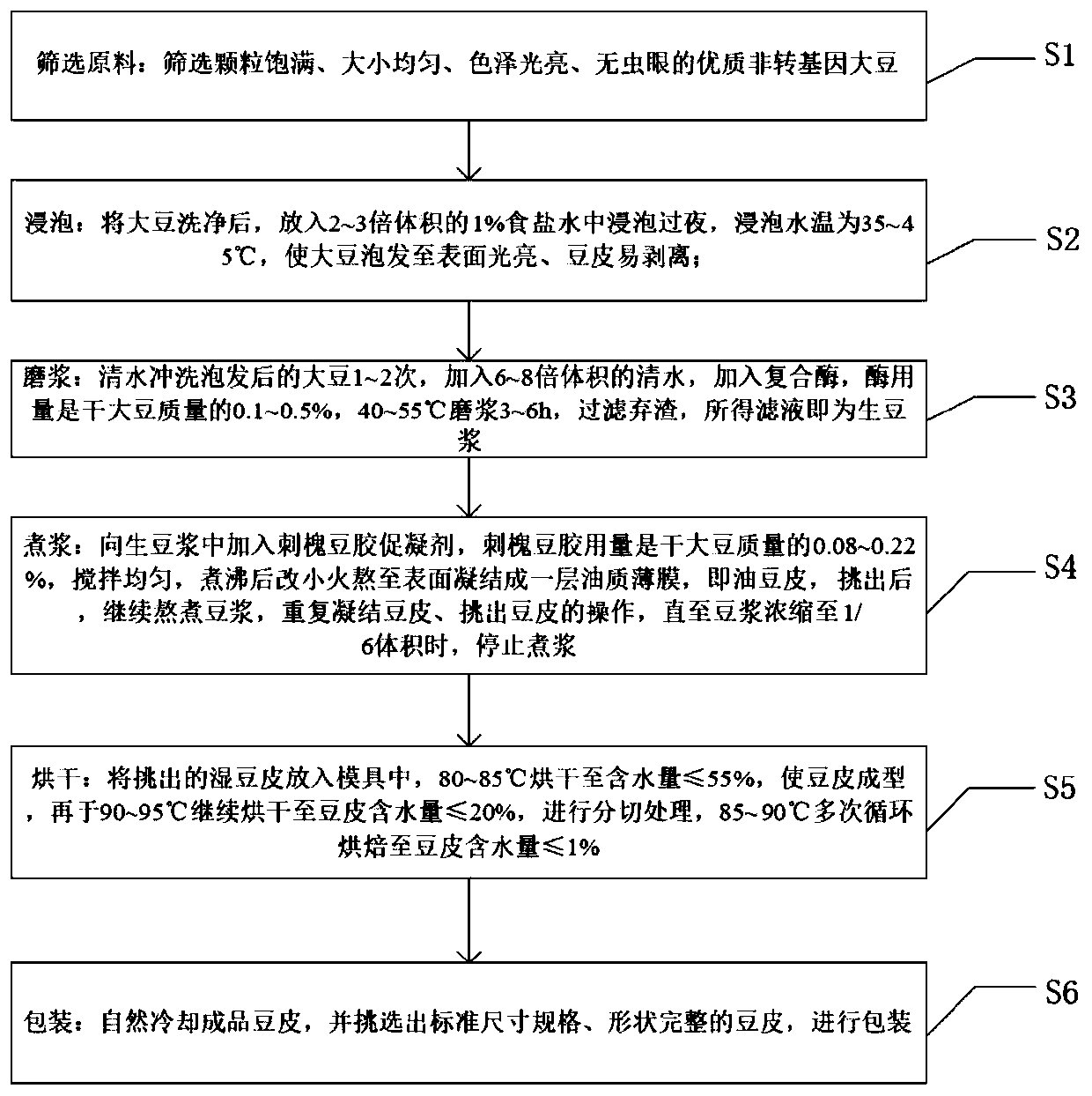

Image

Examples

Embodiment 1

[0022] The production method of non-fried baked bean curd comprises the following steps:

[0023] S1: Screening raw materials: screening high-quality non-GMO soybeans with full grains, uniform size, bright color, and no insect eyes;

[0024] S2: Soaking: After washing the soybeans, put them into 2 times the volume of 1% salt water and soak overnight at a temperature of 35°C, so that the soybeans are soaked until the surface is bright and the skins are easy to peel off;

[0025] S3: Refining: Rinse the soaked soybeans once with clean water, add 6 times the volume of clean water, add compound enzyme, the enzyme dosage is 0.1% of the dry soybean mass, refine at 40°C for 3 hours, filter the discarded residue, and the obtained filtrate is Raw soybean milk; the compound enzyme is formed by mixing amylase, cellulase and hemicellulase in a mass ratio of 10:0.5:1;

[0026] S4: Boiling: add locust bean gum coagulant to raw soybean milk, the amount of locust bean gum is 0.08% of the dry...

Embodiment 2

[0030] The production method of non-fried baked bean curd comprises the following steps:

[0031] S1: Screening raw materials: screening high-quality non-GMO soybeans with full grains, uniform size, bright color, and no insect eyes;

[0032] S2: Soaking: After washing the soybeans, put them into 2.5 times the volume of 1% salt water and soak them overnight. The soaking water temperature is 40°C, so that the soybeans are soaked until the surface is bright and the skins are easy to peel off;

[0033] S3: Refining: Rinse the soaked soybeans with clean water once, add 7 times the volume of clean water, add compound enzyme, the enzyme dosage is 0.2% of the dry soybean mass, refine at 45°C for 5 hours, filter the discarded residue, and the obtained filtrate is Raw soybean milk; the compound enzyme is formed by mixing amylase, cellulase and hemicellulase in a mass ratio of 10:1:2;

[0034] S4: Boiling: add locust bean gum coagulant to the raw soybean milk, the amount of locust bean ...

Embodiment 3

[0038] The production method of non-fried baked bean curd comprises the following steps:

[0039] S1: Screening raw materials: screening high-quality non-GMO soybeans with full grains, uniform size, bright color, and no insect eyes;

[0040] S2: Soaking: After washing the soybeans, put them into 3 times the volume of 1% salt water and soak overnight at a temperature of 45°C, so that the soybeans are soaked until the surface is bright and the skins are easy to peel off;

[0041] S3: Refining: Rinse the soaked soybeans twice with clean water, add 8 times the volume of clean water, add compound enzyme, the enzyme dosage is 0.3% of the dry soybean mass, refine at 50°C for 6 hours, filter the discarded residue, and the obtained filtrate is Raw soybean milk; the compound enzyme is formed by mixing amylase, cellulase and hemicellulase in a mass ratio of 10:1.5:3;

[0042] S4: Boiling: add locust bean gum coagulant to the raw soybean milk, the amount of locust bean gum is 0.18% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com