Chip-collecting device

A technology for recycling devices and swarf, which is applied in maintenance and safety accessories, electrode maintenance, electrode characteristics, etc., can solve problems such as increased load on the drive unit, device failure, etc., and achieves the effect of high swarf recycling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. It should be noted that the following description of the preferred embodiments is exemplary only in nature.

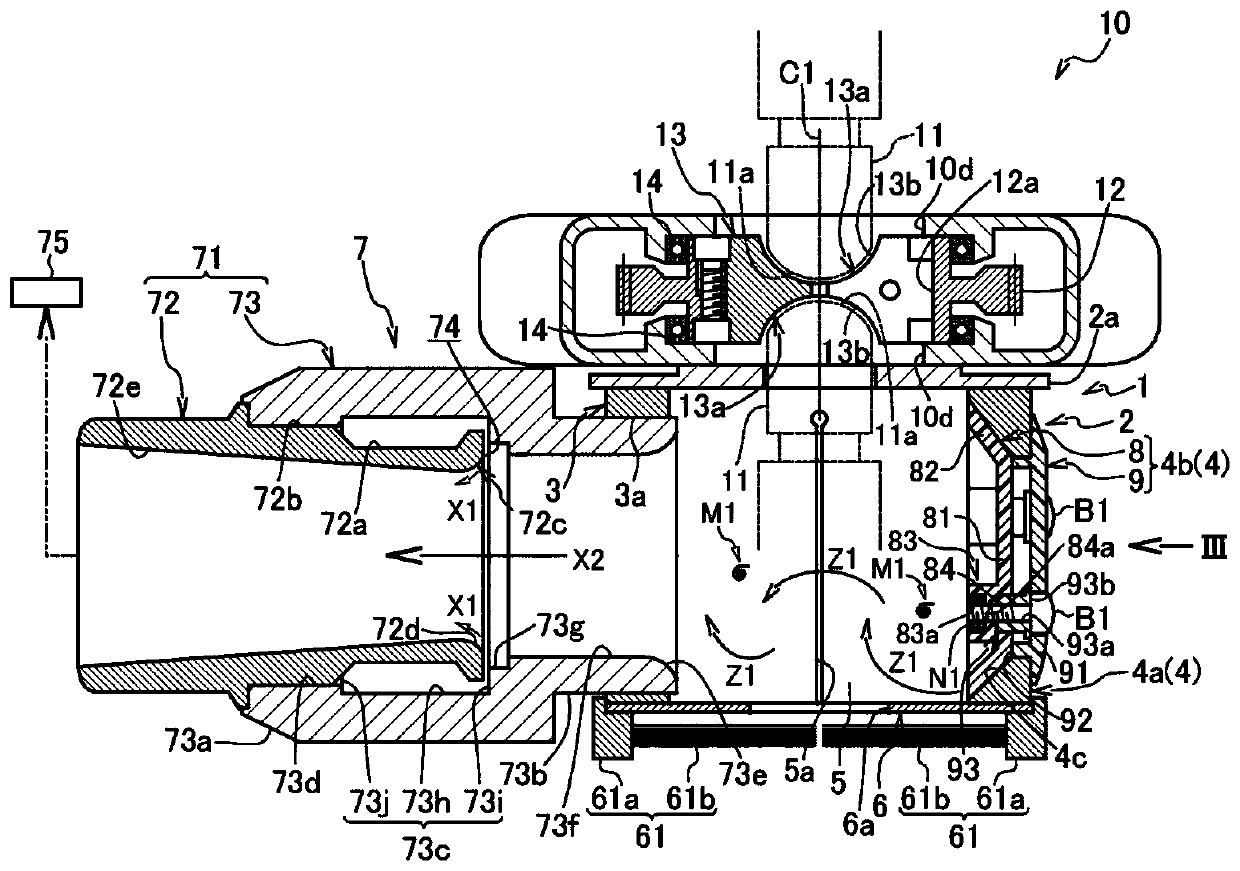

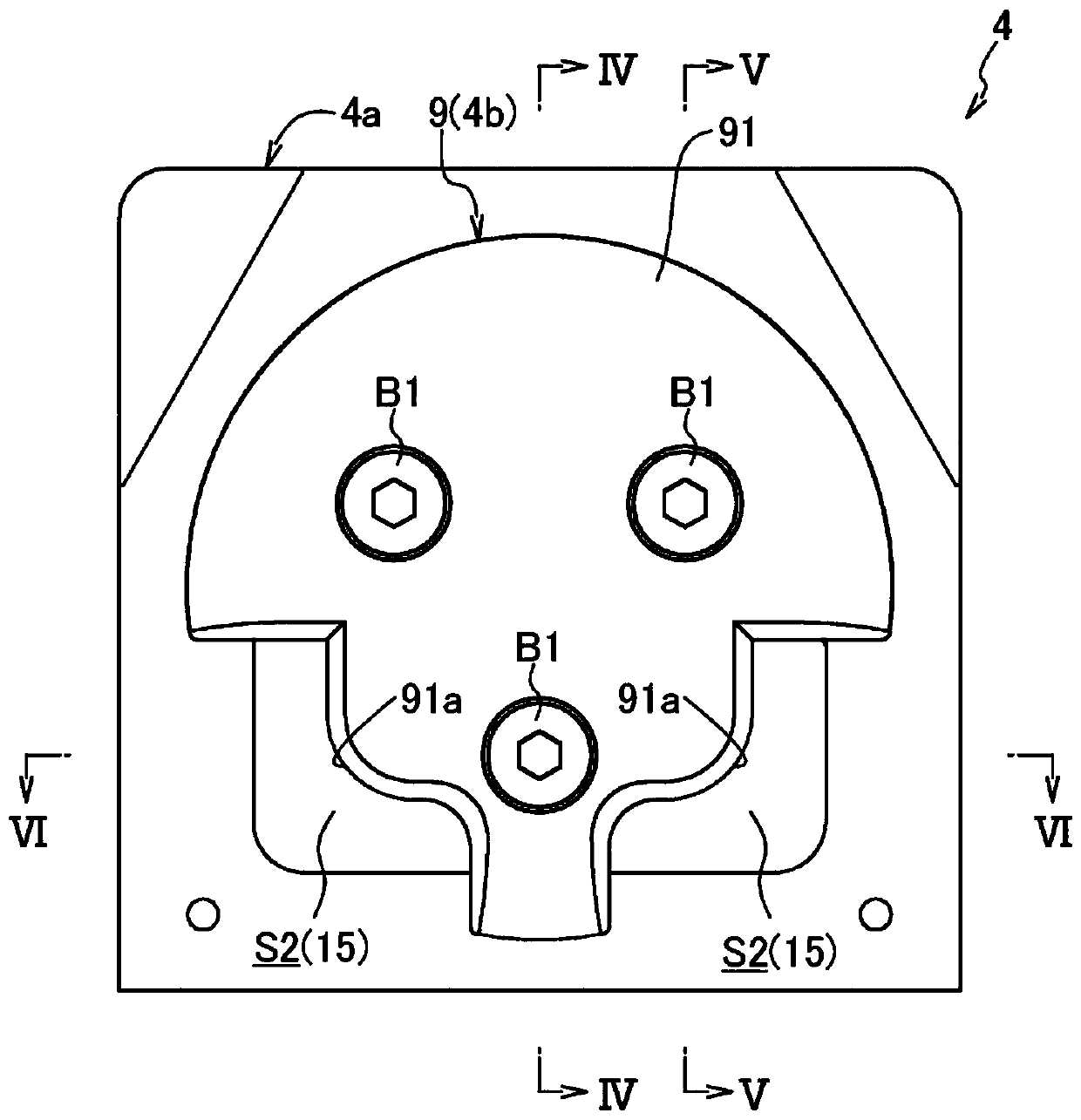

[0034] figure 1 A tip dresser 10 to which the chip recovery device 1 according to the embodiment of the present invention is mounted is shown. Such as figure 2 As shown, the swarf recovery device 1 is used to recover swarf M1 generated when the tips 11 a of a pair of electrode tips 11 attached to a spot welding torch are respectively cut by the tip dresser 10 .

[0035] Such as figure 1 As shown, the above-mentioned electrode tip dresser 10 includes: a substantially cylindrical motor casing part 10a with the cylinder centerline direction facing the up and down direction; A plate-shaped gear case part 10b; and a shock absorbing mechanism part 10c attached to the back of the motor case part 10a to absorb the impact applied to the motor case part 10a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com