Detection and measurement quick alignment device for the production of heavy truck spare parts

A technology for detection, measurement, and spare parts, which is applied in the field of detection and measurement quick alignment devices. It can solve the problems of troublesome alignment process, affecting work efficiency, and long alignment work hours, etc., and achieves intuitive display, improved reading speed, and convenient measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

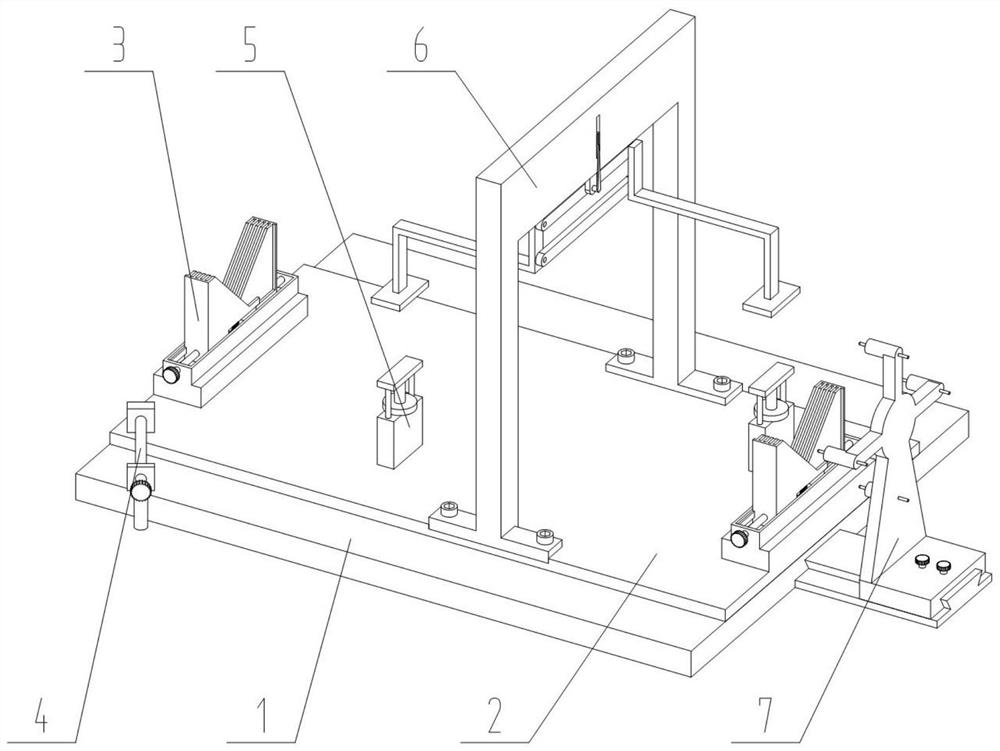

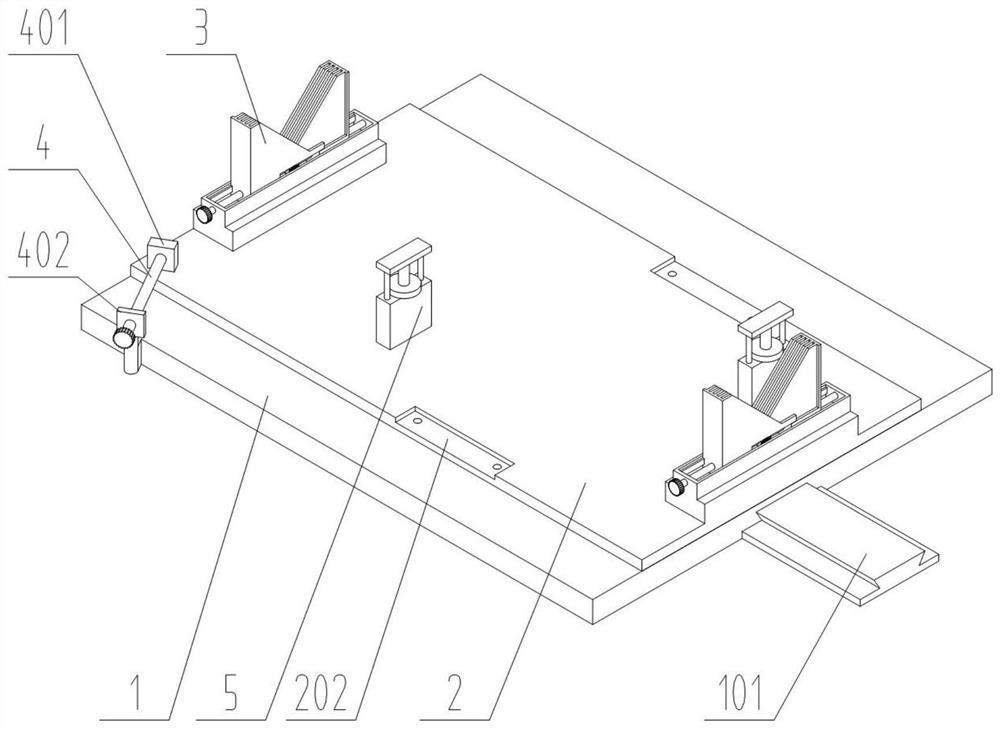

[0037] as attached figure 1 to attach Figure 12 Shown:

[0038] The present invention provides a detection and measurement quick alignment device for the production of heavy truck spare parts, including: a bottom plate 1 and a crankshaft part 8; a group of bottom swing adjustment plates 2 are axially connected to the top of the bottom plate 1; The side is connected to the bottom plate 1 through a set of offset adjustment screws 4; a set of adjustable support blocks 3 are arranged on the left and right sides of the upper end surface of the bottom swing adjustment plate 2; two sets of leveling blocks are fixedly connected to the upper end surface of the bottom swing adjustment plate 2 The support block 5; the upper end surface of the bottom swing adjustment plate 2 is fixedly connected with a group of leveling and alignment devices 6 by bolts; the upper end surface of the bottom plate 1 is slidingly connected to the right side with a group of end surface alignment devices 7; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com