Device for positioning placement position of ADAS calibration target plate and positioning method

A technology for calibrating device and target board, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of increasing data transmission and processing burden, cumbersome steps, complex calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1. An auxiliary ADAS calibration device

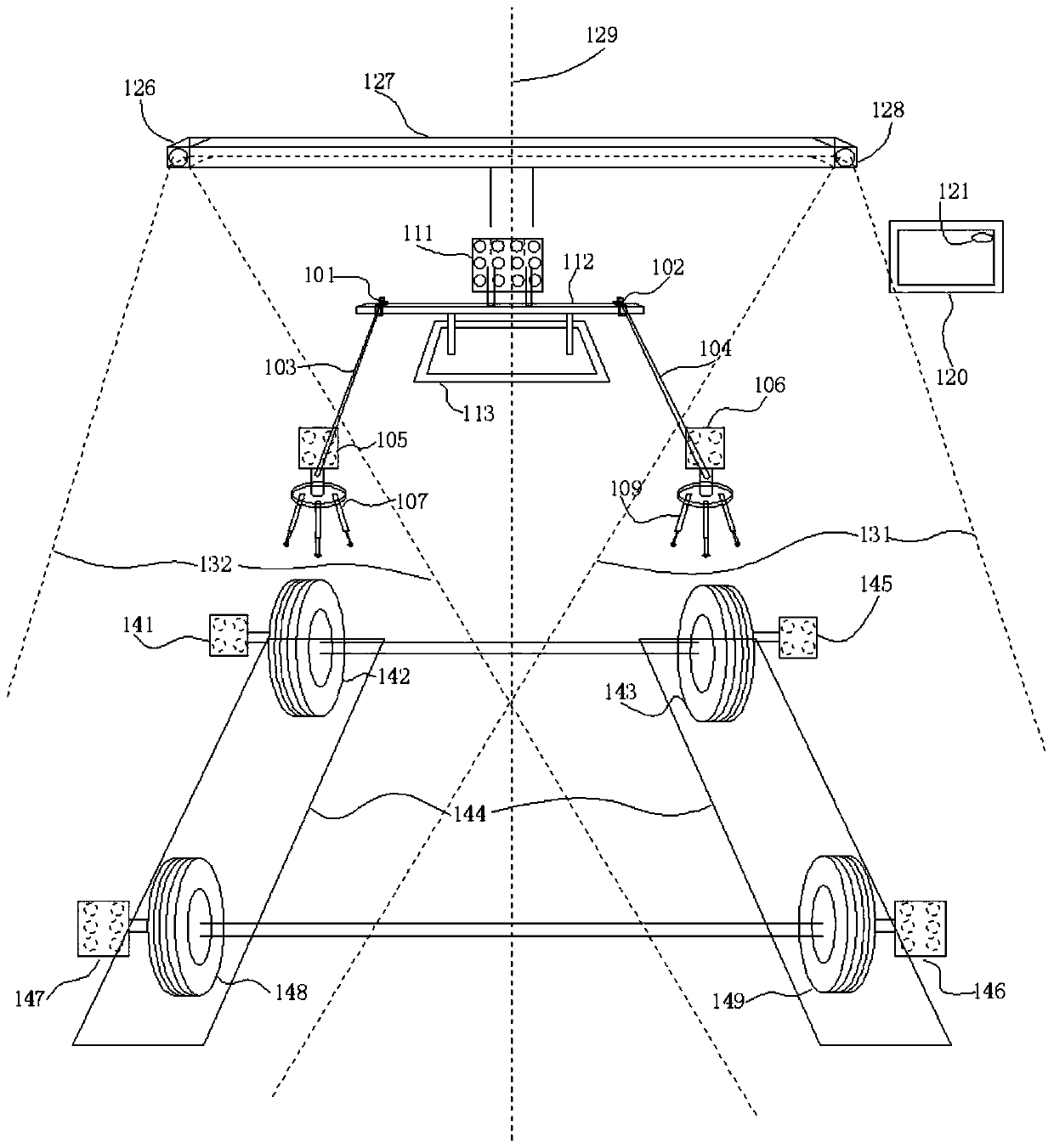

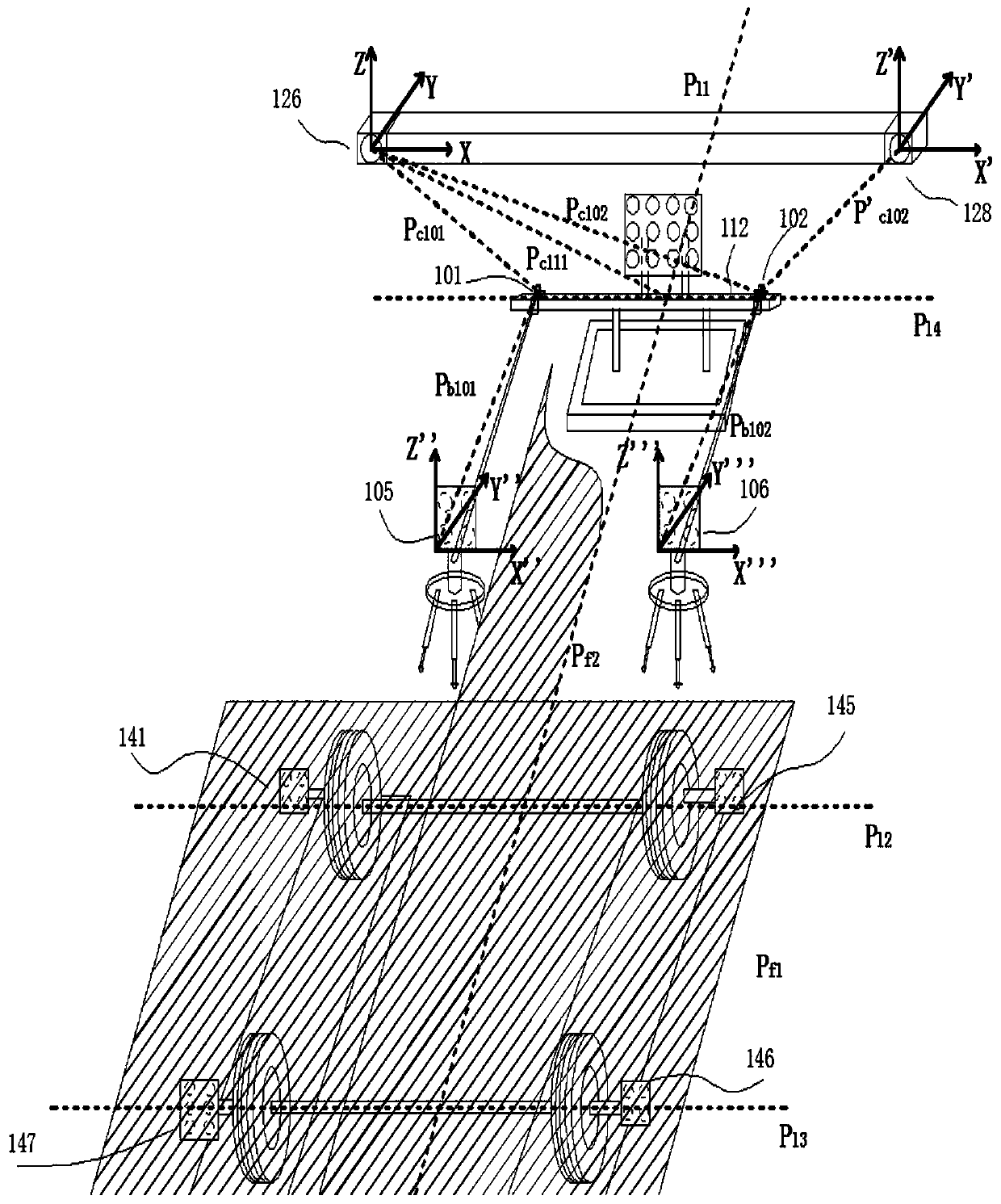

[0077] like figure 1 As shown, an auxiliary ADAS calibration device includes fixed terminals 101, 102, connecting rods 103, 104, positioning target boards 105, 106, positioning target board support frames 107, 109, ADAS calibration board 111, support frame beams 112, wheels Cameras 126, 128 of the locator, target boards 141, 145, 146, 147 of the wheel locator, and a working host 120;

[0078] The ADAS calibration board 111 is placed in front of the vehicle,

[0079] The ADAS calibration plate 111 is fixed at the middle position of the support frame beam 112, and the support frame beam 112 is placed on the support base 113 to realize convenient adjustment of the placement position of the ADAS calibration plate 111,

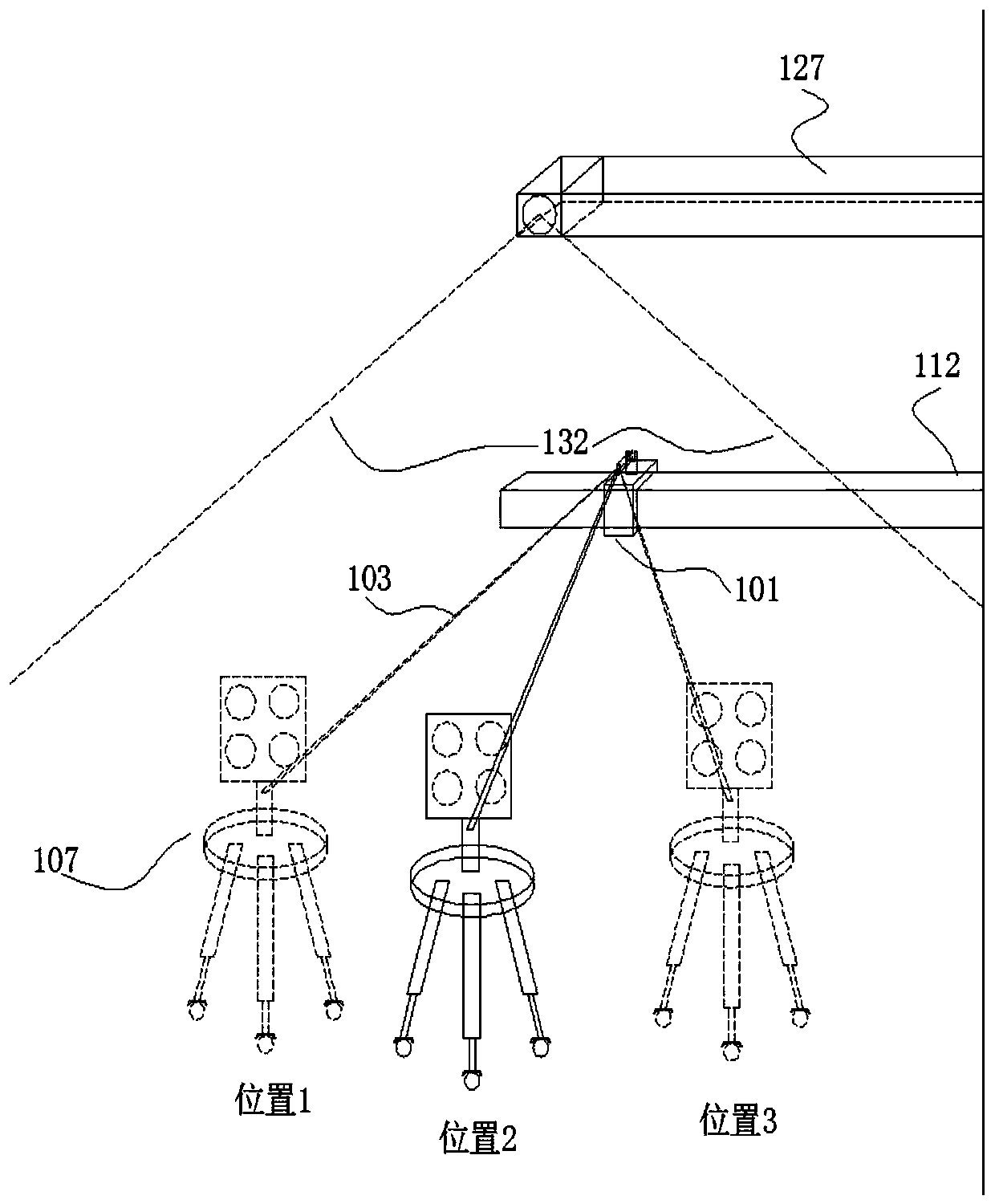

[0080] One end of the connecting rods 103, 104 is fixedly connected to the positioning target boards 105, 106 respectively, and the other end is movably connected to the support frame beam 112 through th...

Embodiment 2

[0098] Embodiment 2, Auxiliary ADAS calibration device with a single set of connecting rod, fixed terminal, positioning target board and positioning target board support frame

[0099] In embodiment 1, the number of connecting rods, fixed terminals, positioning target boards and positioning target board support frames in the auxiliary ADAS calibration device is two, and each different part is connected to each other to form a group, so that the auxiliary ADAS calibration device includes two A group of functional parts, each group is connected to the two ends of the crossbeam of the ADAS calibration equipment, and when the auxiliary ADAS calibration device is connected to the ADAS calibration equipment, the two sets of functional parts need to be connected to the two ends of the ADAS calibration equipment through fixed terminals.

[0100] However, as other possible options for this example, this example can also be set as follows:

[0101] In order to save costs, the two sets o...

Embodiment 3

[0102] Embodiment 3, using the auxiliary ADAS calibration device of embodiment 1 or 2 to locate the positioning method of the ADAS target board

[0103]The auxiliary ADAS calibration device is placed directly in front of the vehicle to be calibrated, between the wheel aligner and the vehicle to be calibrated, and then the wheel aligner is used to place the ADAS calibration equipment so that the target identification (positioning target boards 105, 106 and the target boards 141, 145, 146, 147 of the wheel aligner fixed on the wheel rims 142, 143, 148, 149 are simultaneously in the field of view 132 and 131 of the cameras 126, 128 of the wheel aligner, so that the wheel aligner can be utilized The instrument simultaneously measures the spatial position of the centerline 129 of the vehicle to be calibrated and the spatial position of the ADAS calibration board 111, so as to accurately place the horizontal center of the ADAS calibration board 111 in front of the vehicle at a suitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com