Automatic cloth measuring machine

A cloth measuring machine and momentum technology, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of cloth elongation, low work efficiency, measurement data errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

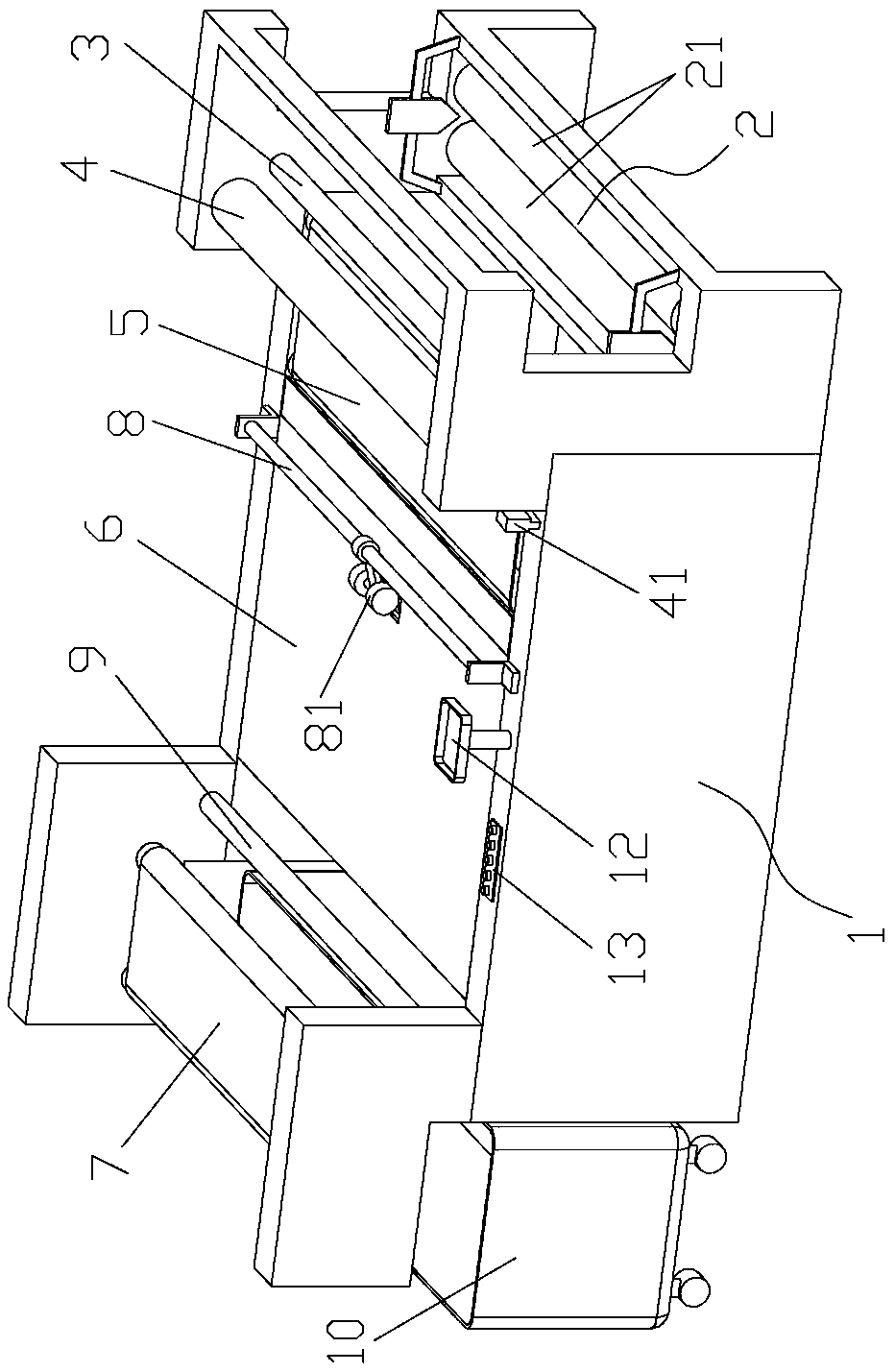

[0023] Such as figure 1 , 2 As shown in , 3, the automatic cloth measuring machine includes a main frame 1, and the main frame 1 is sequentially provided with a cloth ejecting mechanism 2, a cloth guide roller 3, a driving roller 4, a conveyor belt device 1 5, and a platform plate along the cloth feeding direction 6 and the conveyor belt device 2 7; the cloth ejection mechanism 2 includes two cloth ejection rollers 21, and the two cloth ejection rollers 21 are horizontally installed on the main frame 1, and the cloth roller 11 to be measured is placed between the two cloth ejection rollers 21; The roller 4 is driven by an independent driving device, and the active roller 4 is used to feed the cloth, so that the cloth naturally falls on the conveyor belt device 1 5, eliminating the influence of the elasticity of the cloth; the main frame 1 on the side of the active roller 4 is equipped with a photoelectric sensor Controller one 41, the other side of corresponding main frame 1 ...

Embodiment 2

[0034] Such as Figure 4 Shown, under the situation of lower cloth receiving frame 10 height, conveyer belt device two 7 and platform plate 6 are arranged in parallel, cancel cloth guide roller two 9, all the other settings are unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com